BEMO standing seam roof

Versatile and sustainable metal roof system for almost any building geometry

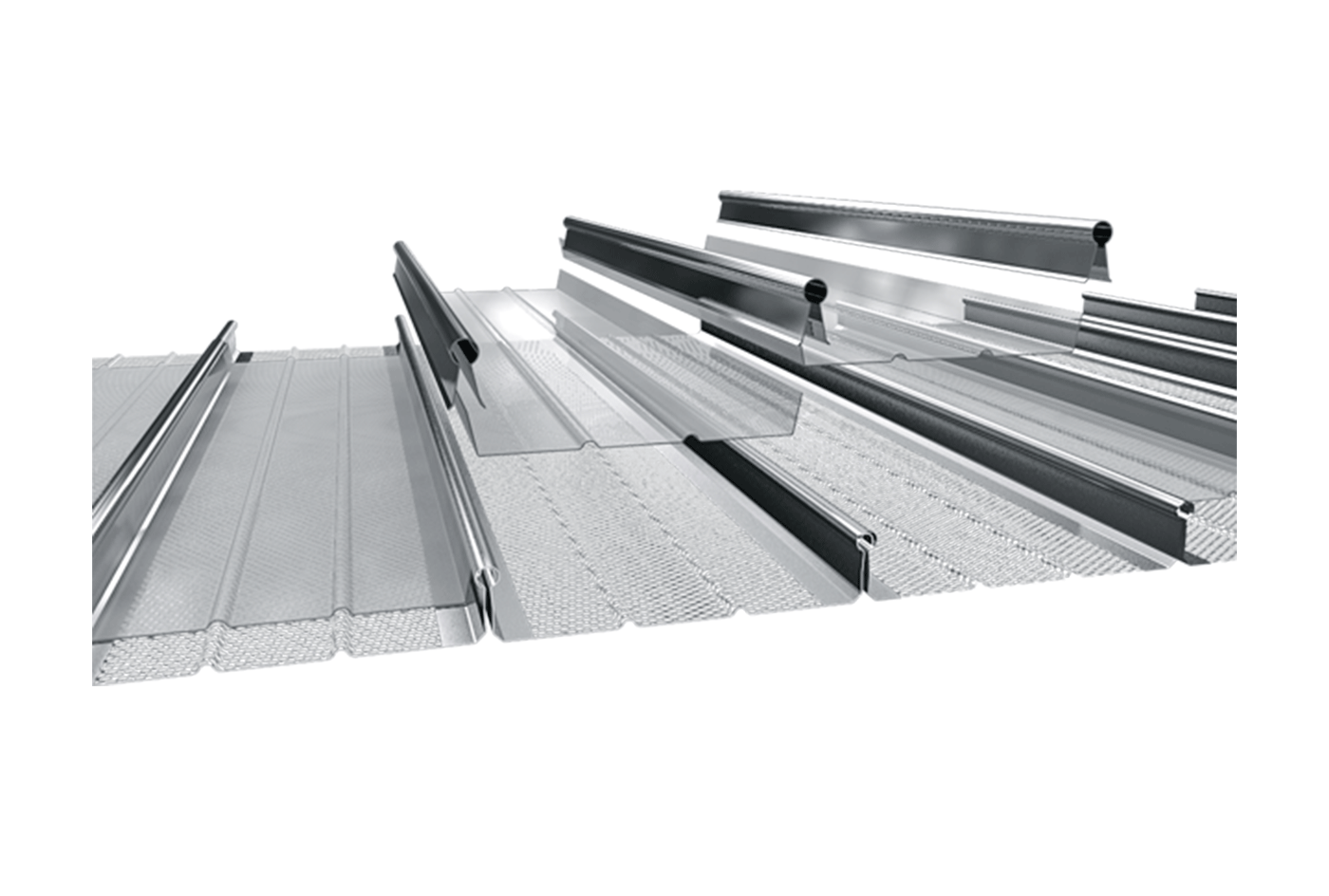

Few roofing systems can meet as many different requirements as a multi-skin metal roof system with standing seam profiles. Whether for new construction or renovation, the BEMO standing seam roof meets all the demands of modern architecture.

The profiles are self-supporting and are installed without penetration. The variable panel length of the standing seam roofing system eliminates cross overlaps and therefore reduces the risk of leaks. Connections are permanently welded. The BEMO system stands for flexible adaptability of metal roofing to almost any building geometry.

We offer a wide choice of standing seam roof structures, always designed to meet the requirements of the building. Very good thermal and sound transmission values can be achieved.

-

Penetration-free fastening

with BEMO substructure -

Variable profile lengths

up to more than 100 metres -

Flexible adaptability

to almost any building geometry -

Profiled tracks can also be rounded,

convex, concave and curved -

Extensive system accessories

can be retrofitted without penetration -

Very good thermal transmittance values

of < 0.15 W/(m²K) -

Sound transmission values of >50dB

with multi-layer roof structures -

Sustainable roof system

with 100% recyclable aluminium

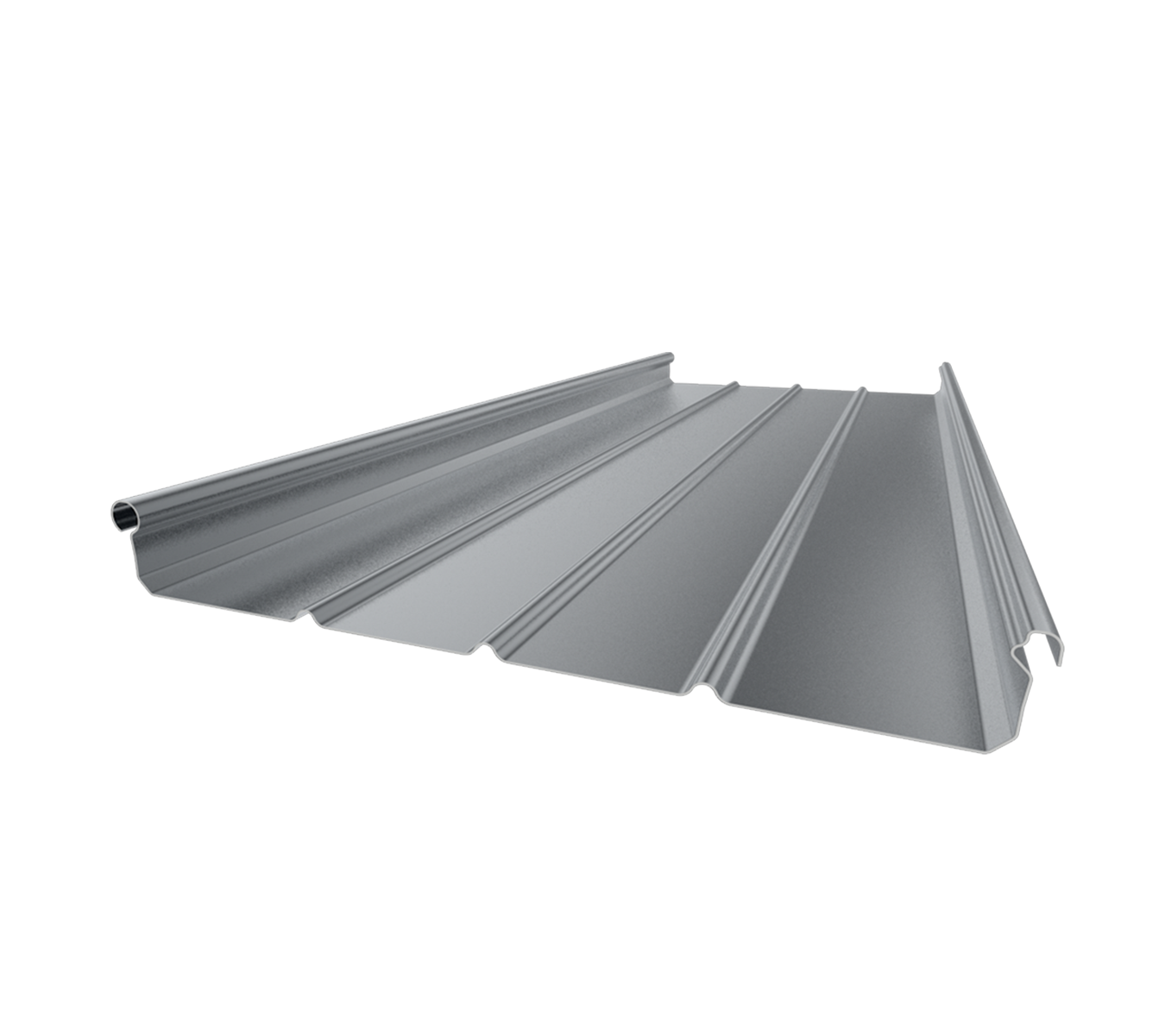

Standing seam roofing for the highest static requirements

High load-bearing capacity and good static values characterize the standing seam roofing system from BEMO

BEMO standing seam profiles guarantee maximum safety in roofing, even for large, flat pitched roofs and special shapes. A standing seam roof system meets the highest structural and acoustic requirements. It adapts to almost any building shape. The visual design freedom of metal roofing is almost limitless due to the free choice of profile shape, material and colour. It is installed without penetration by interlocking on special standing seam brackets.

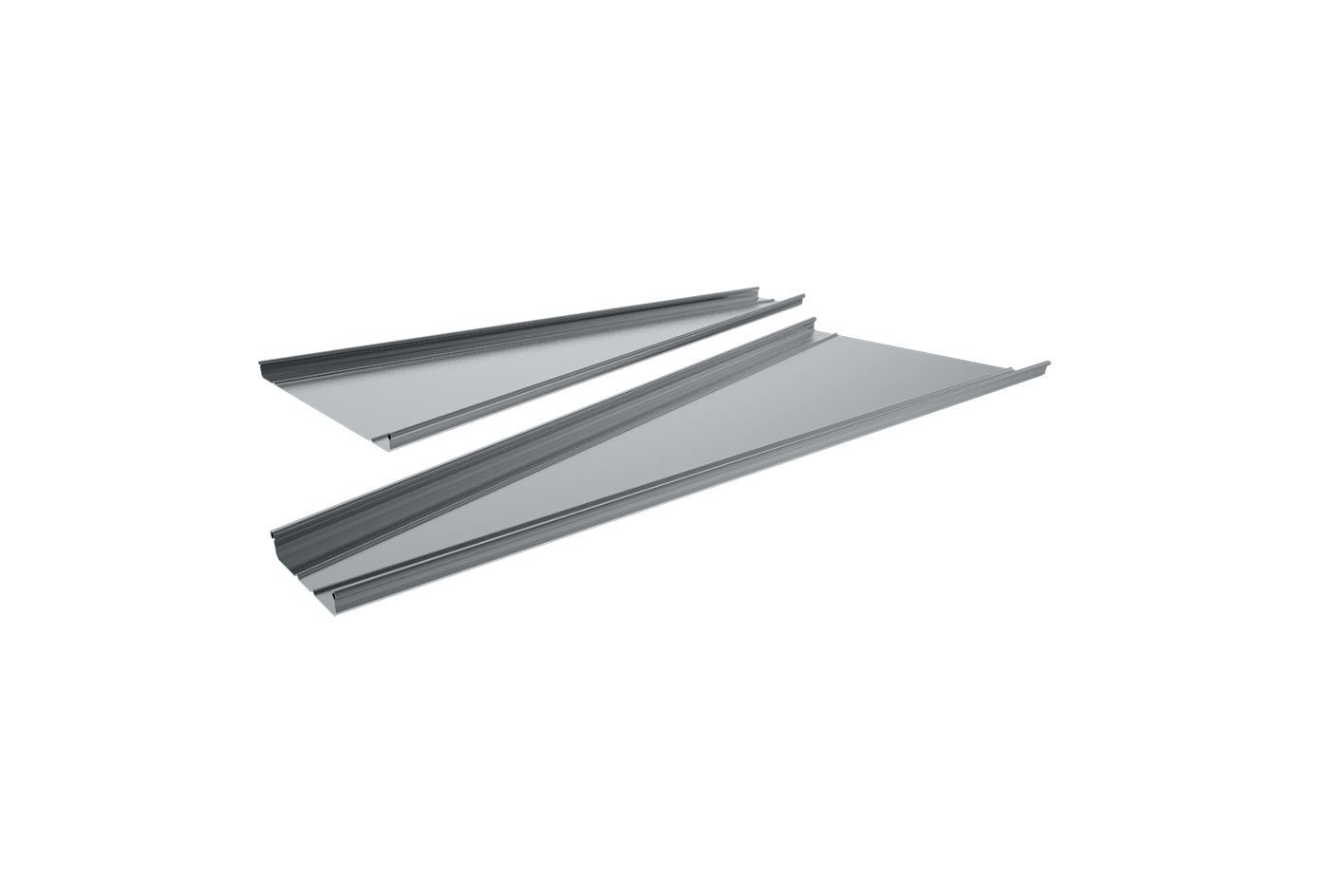

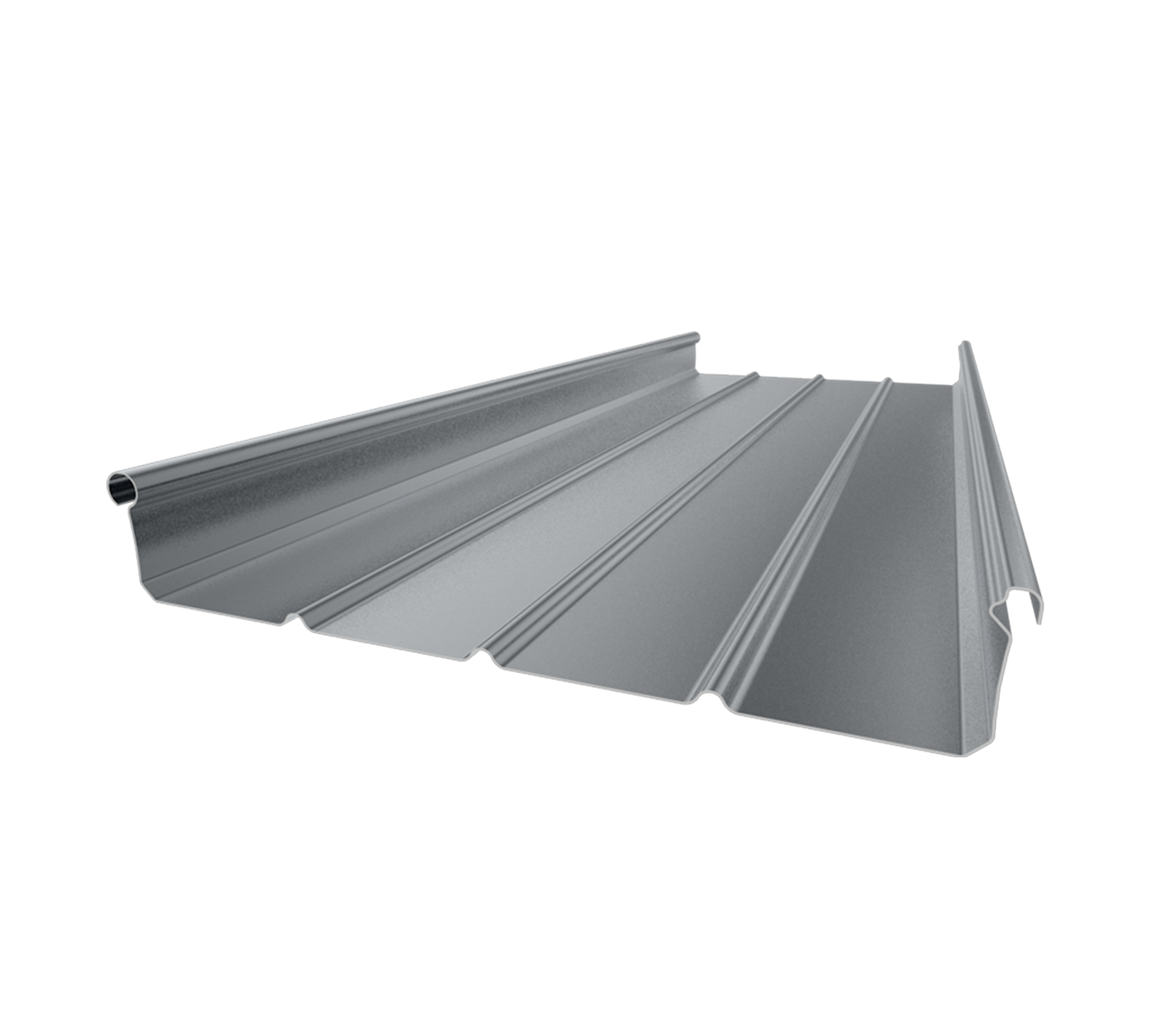

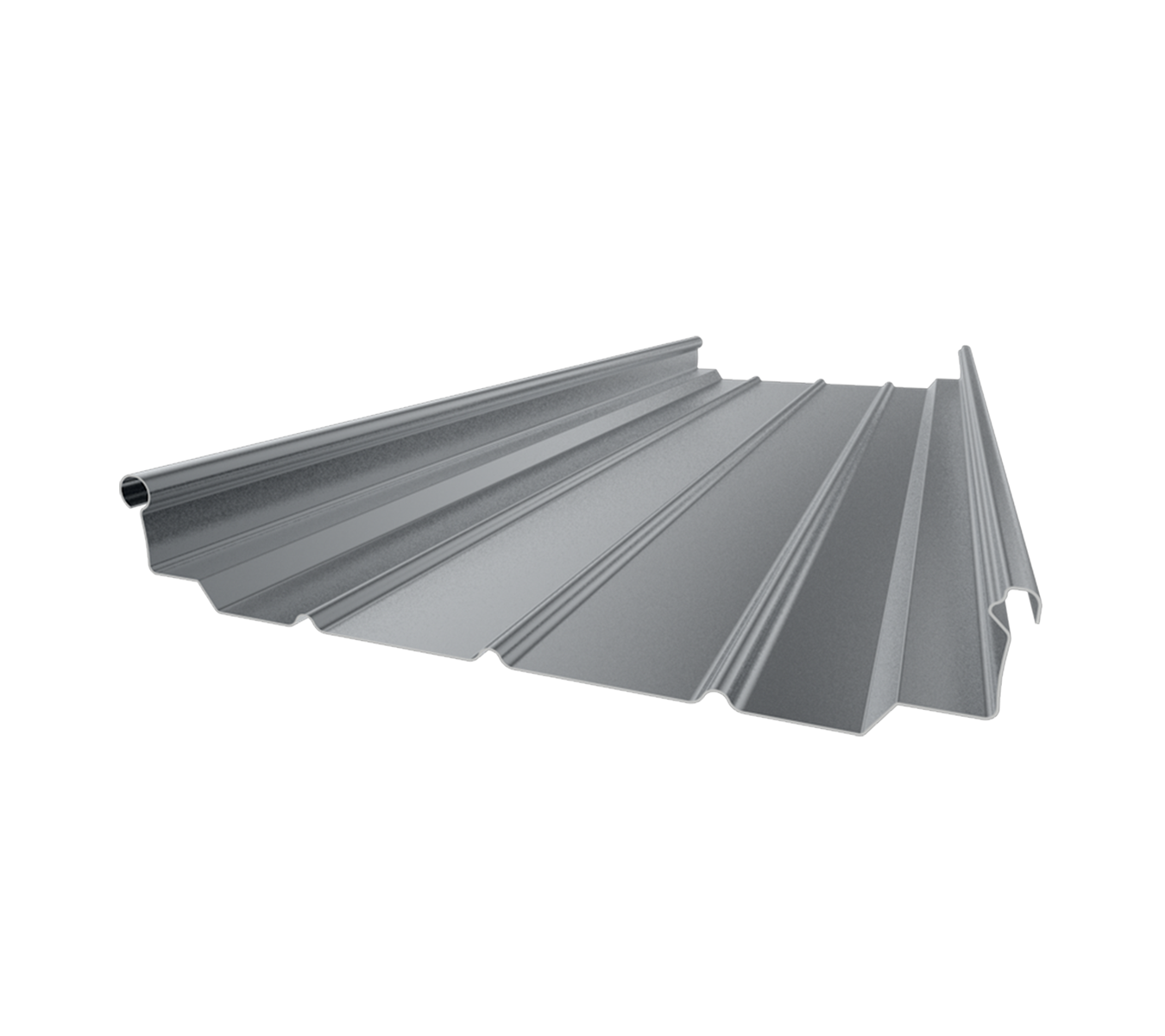

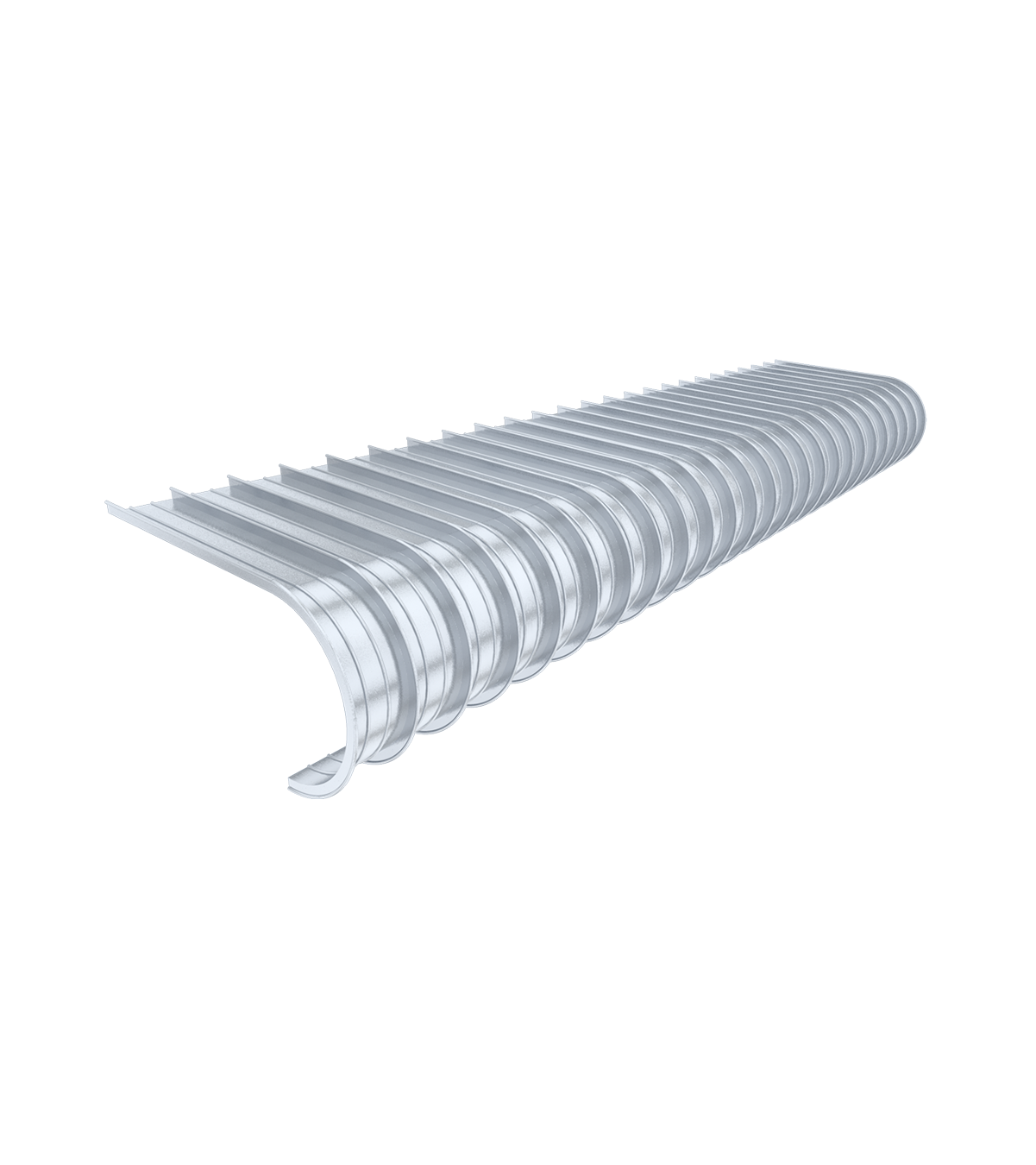

The three proven profile variants can be selected as standing seam roofing for all materials:

N 50 – with 50 mm seam height and variable profile widths. This profile has a delicate and aesthetic appearance and is often used for smaller roof areas such as mono-pitch roofs and residential buildings, as well as in industrial roofing without high snow loads.

N 65 – with 65 mm seam height and variable profile widths. This profile is ideal for flat sloping roofs due to the high seam. It is further distinguished by its very good load-bearing capacity and therefore good static values.

VF 65 – with 65 mm seam height and variable profile widths. When used on rigid insulation and timber boarding, the profile covers the entire surface. A special moulding accommodates the geometry of the bracket foot without imprinting.

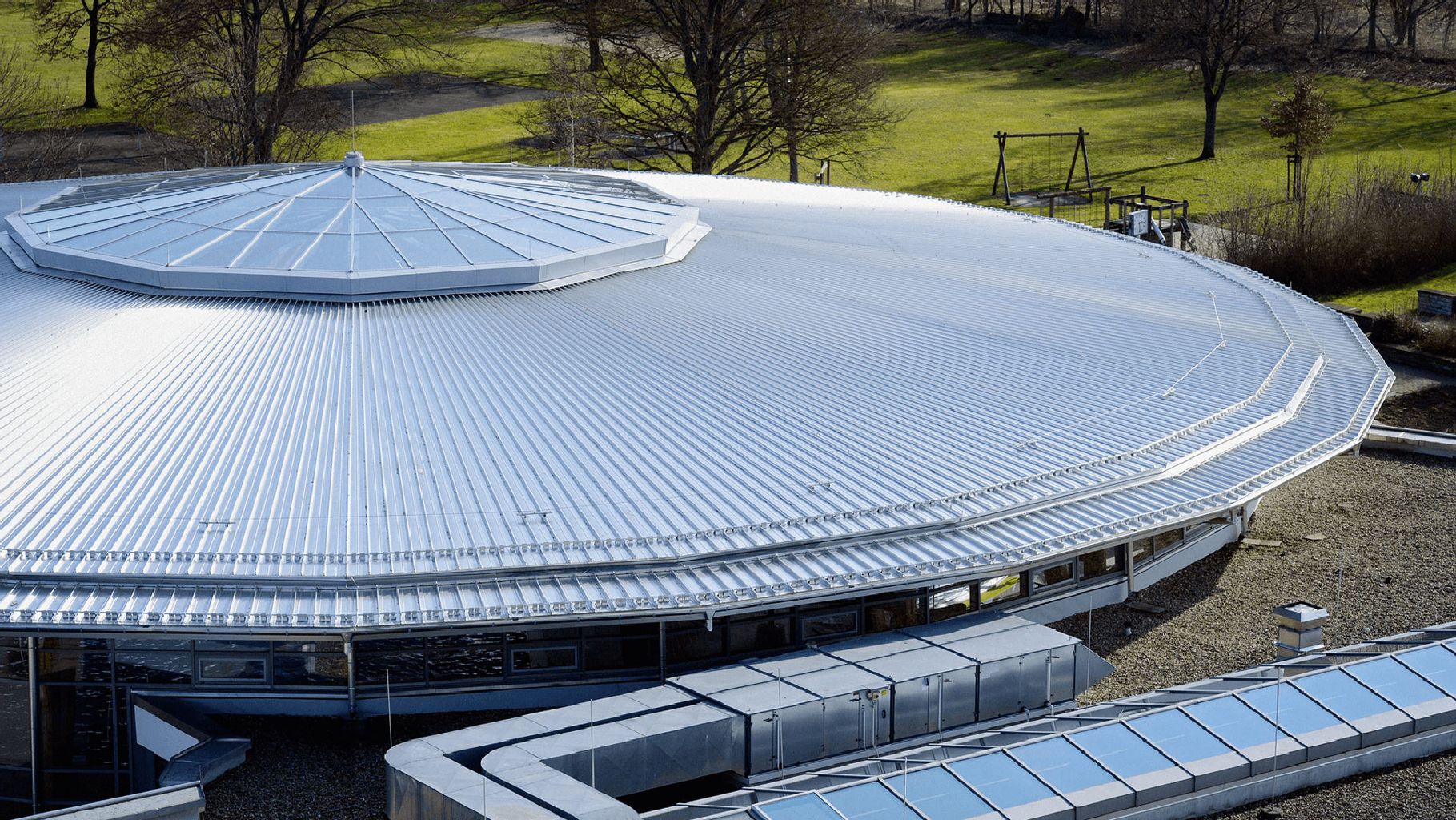

BEMO-MONRO® – Special building shapes with standing seam systems

Creation of individual and unusual building shapes

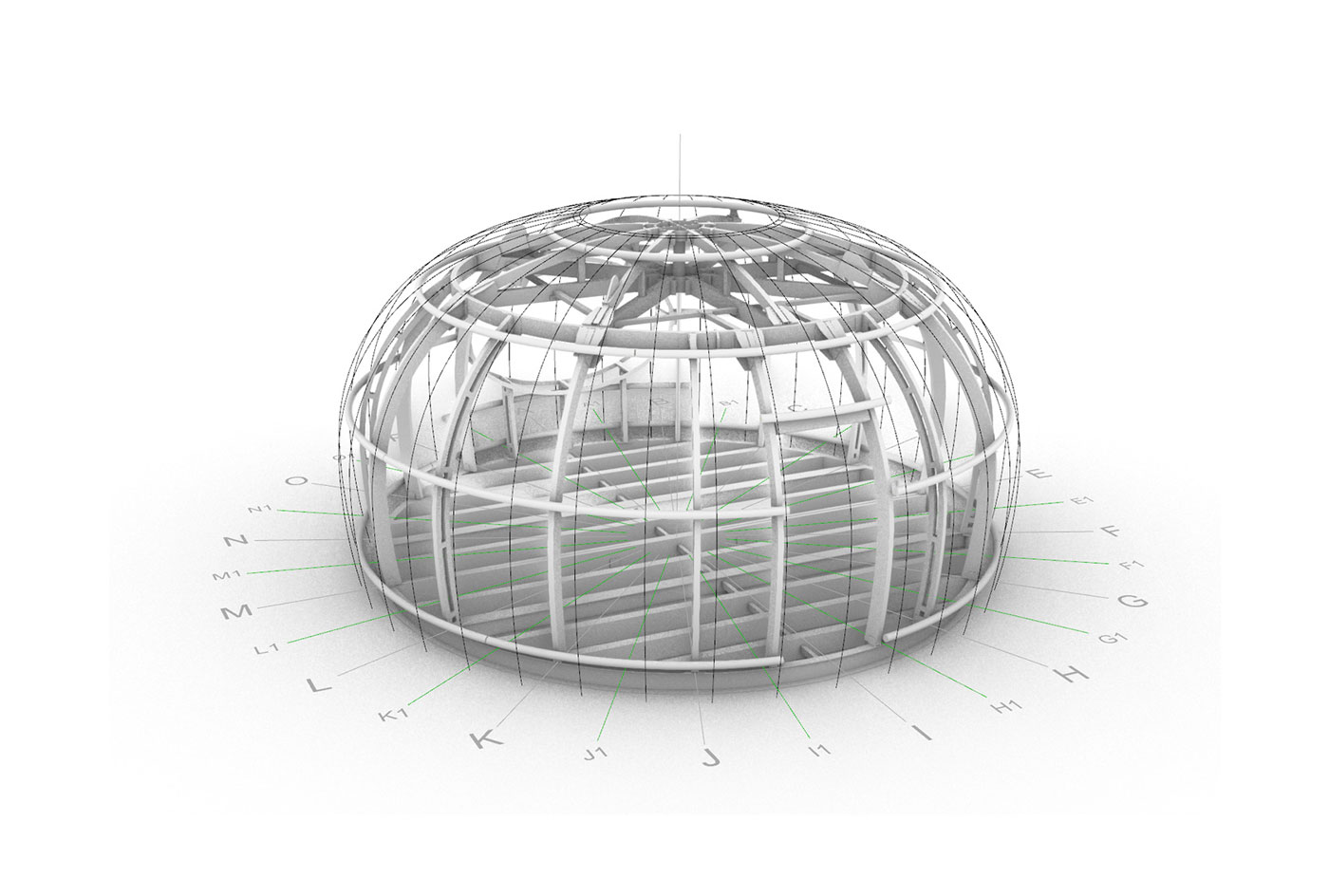

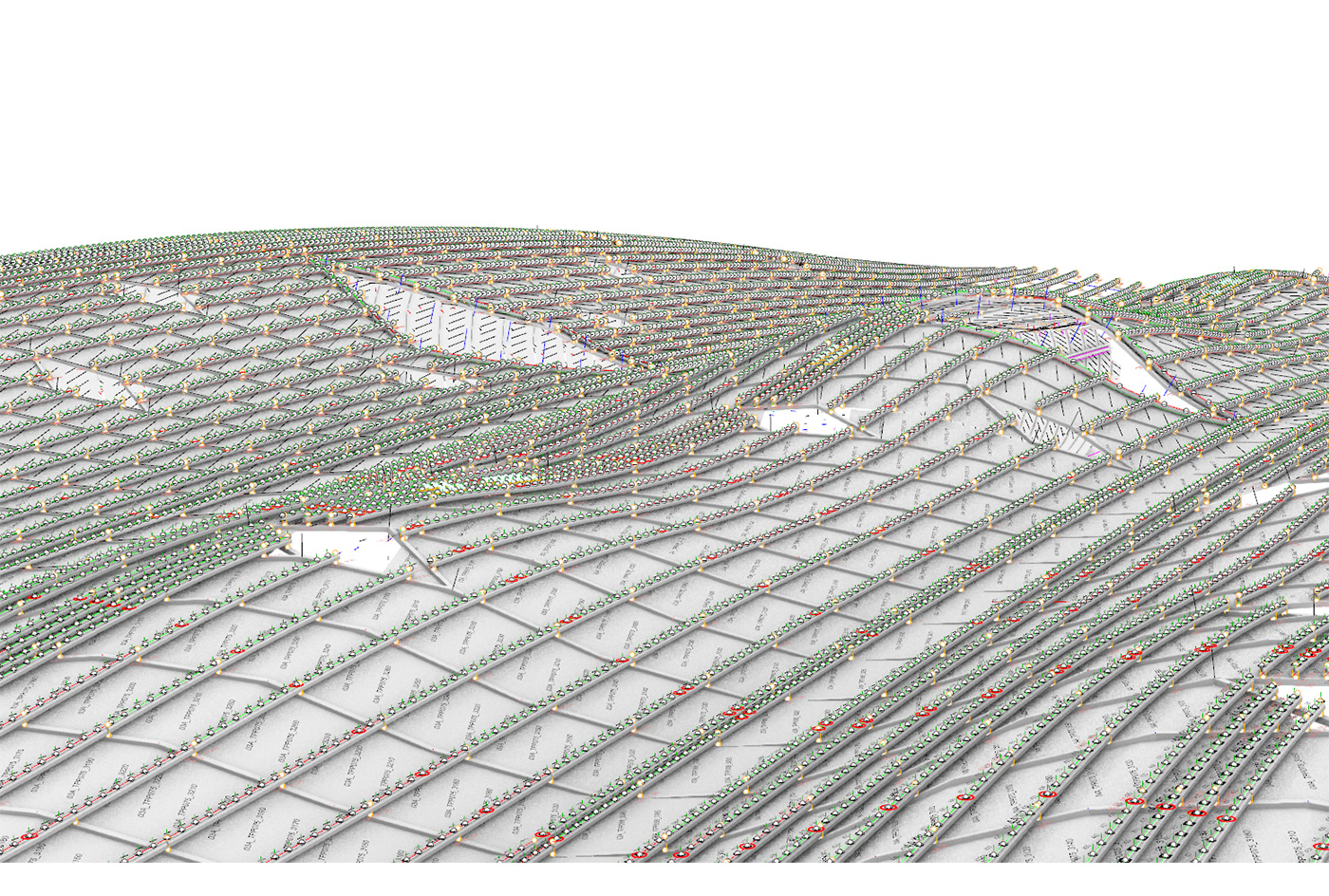

Generally, the MONRO® system is combined with a substructure which allows an adjustment in three dimensions. Unevenness in the supporting structure is no longer a problem, as it can be compensated quickly and easily with the standing seam system. Based on a 3D scan of the supporting structure, BEMO 3D construction plans the system ready for assembly.

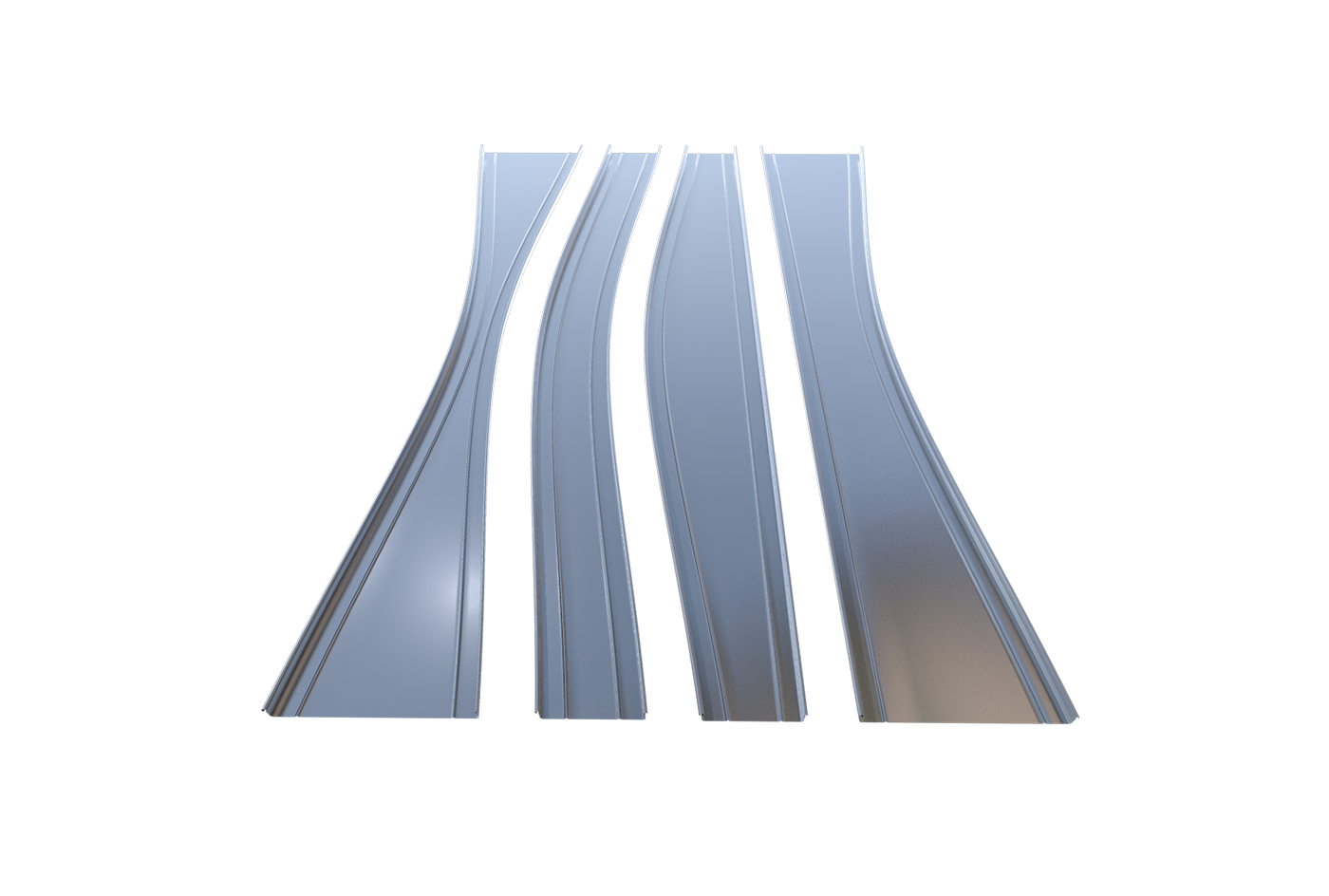

Special conical profiles are ideal for larger circular and conical buildings. With a minimum width of 100 mm and a maximum coverage width of 800 mm, almost any requirement can be met. Finally, the standing seam sheets are precisely formed in a single operation. This avoids time-consuming on-site cutting and makes the standing seam system easy to use.

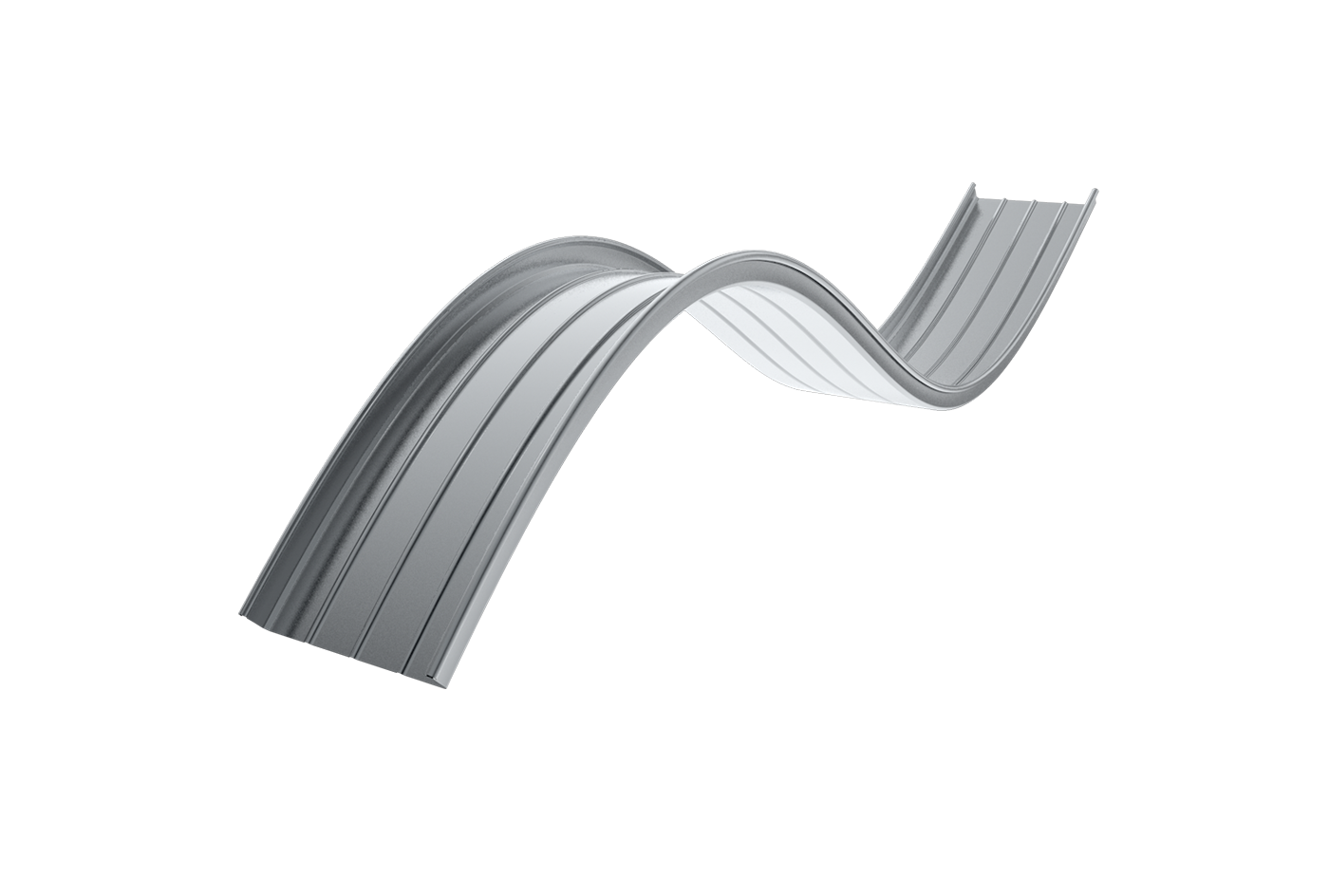

The special BEMO profiles are also available in a curved form and in various materials.

Planning free-form buildings sensibly

Our in-house planning office will be happy to support you in planning your free-form architecture project. Using comprehensive analyses and innovative 3D planning, our BEMO specialist planners create geometries and area optimisations of any roof shape.

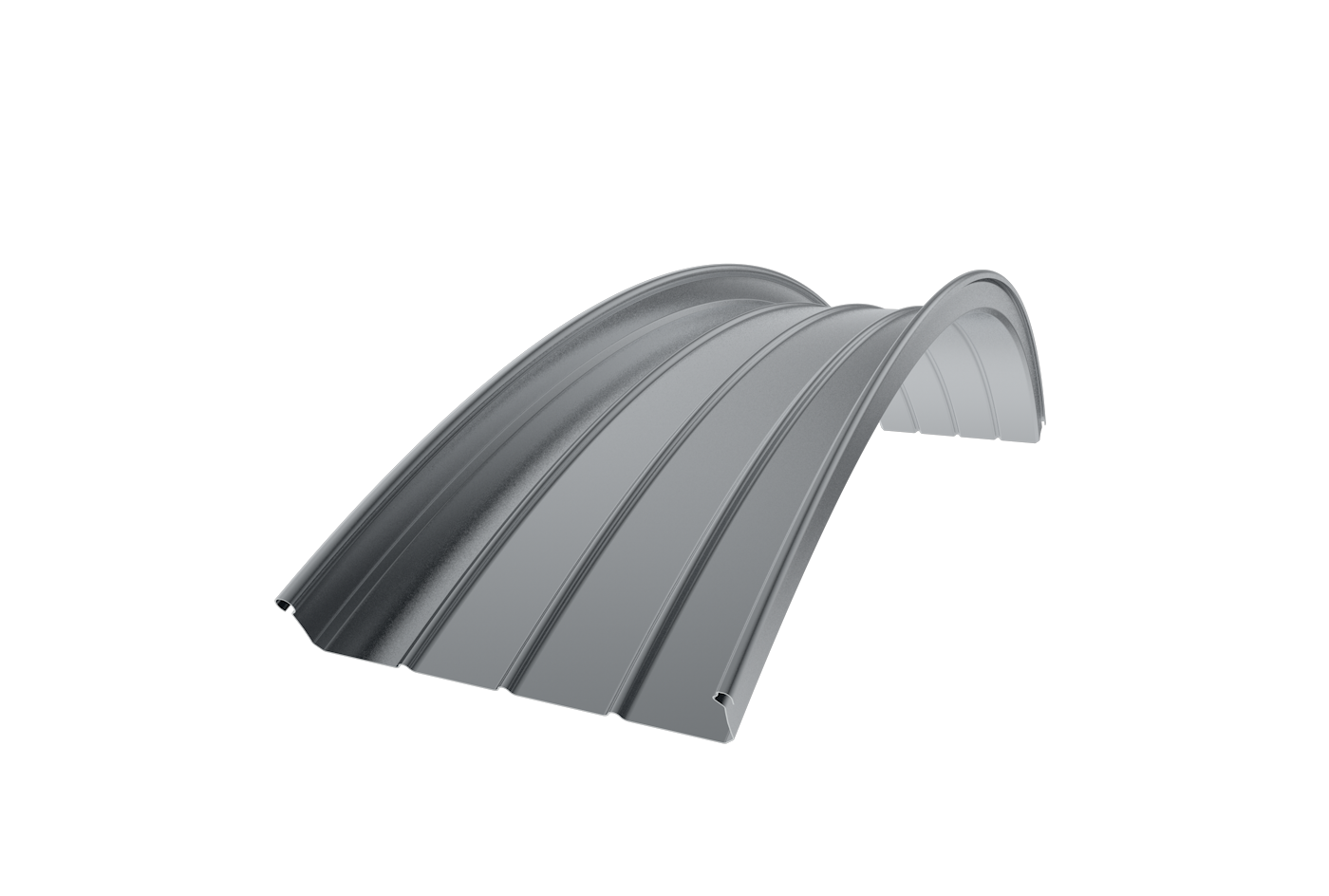

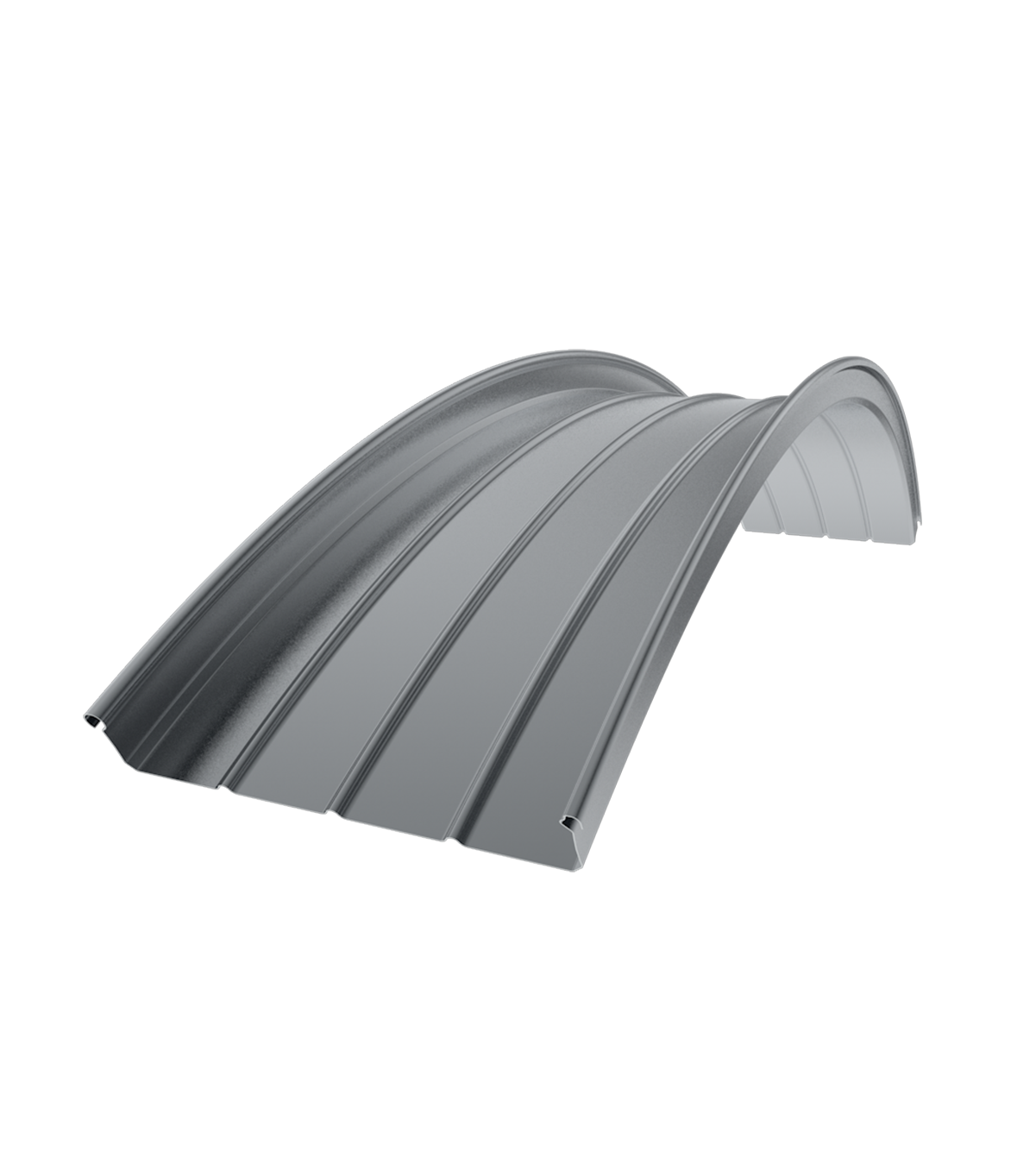

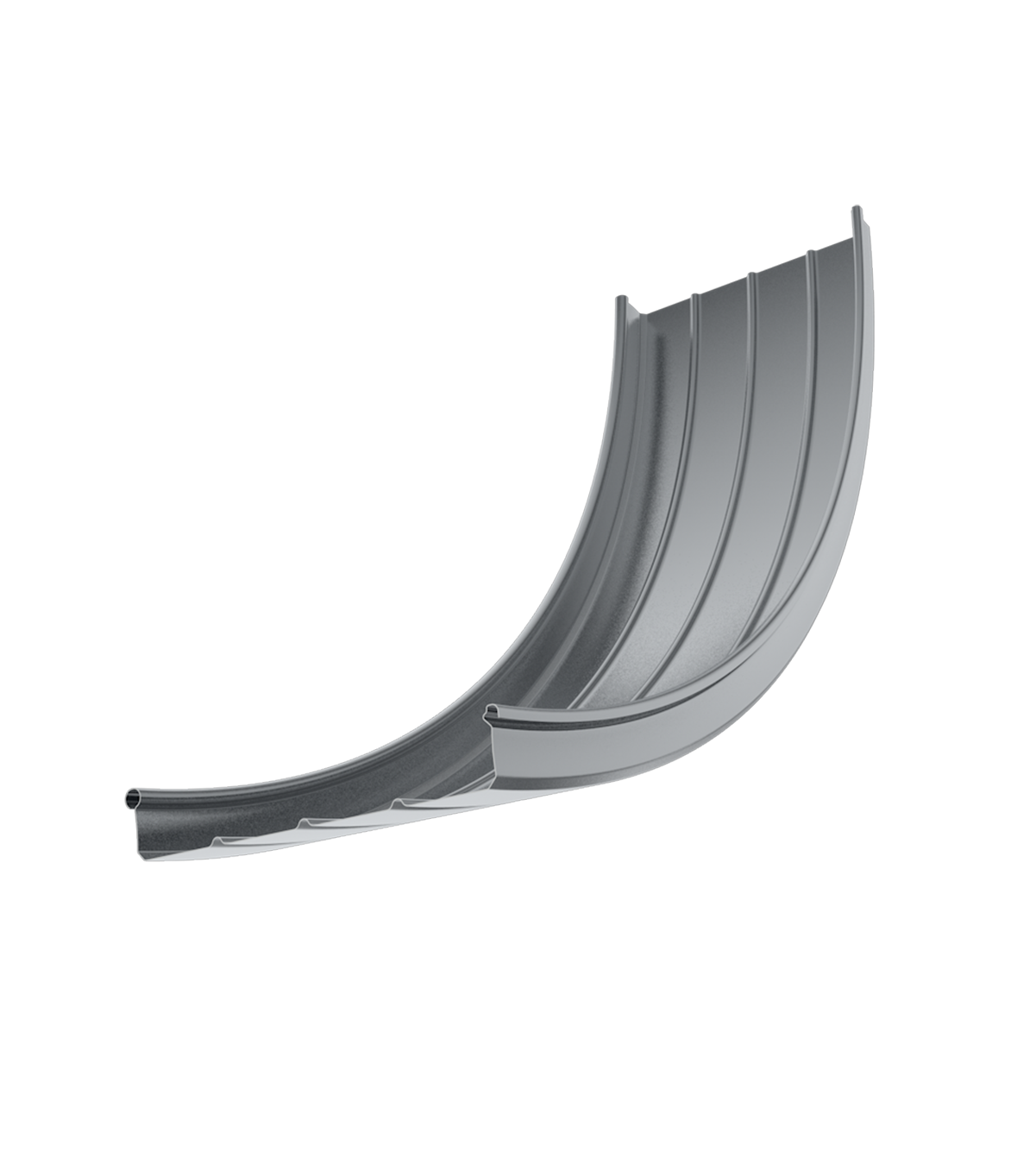

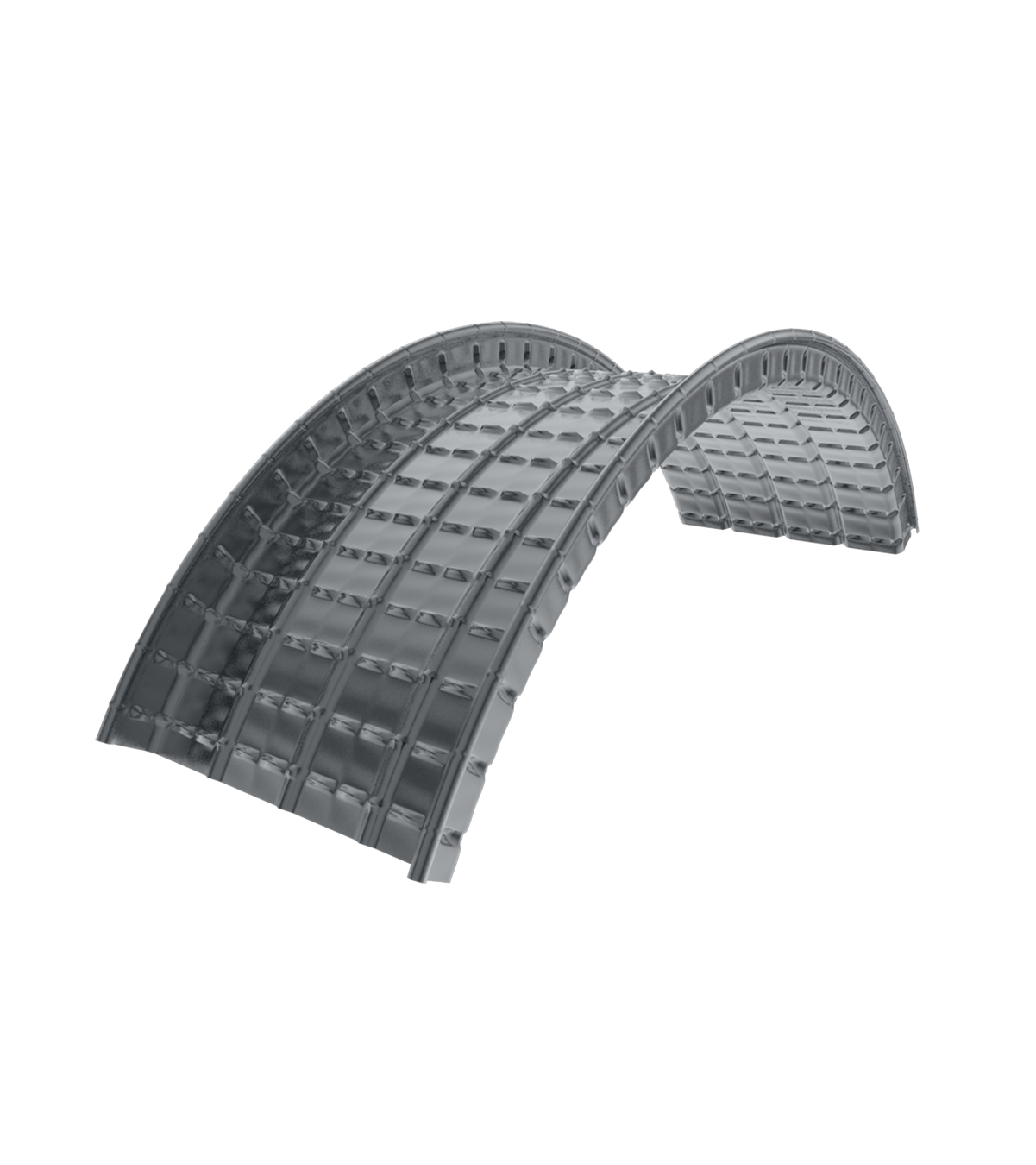

A metal roof curved to the smallest radii for flowing building forms

Precisely fitting, curved shape for maximum functional reliability with BEMO

The curvature can be either concave, convex or concave-convex – the standing seam sheets can be curved to the smallest radii. Depending on the material and profile, minimum radii of less than 800 mm are possible.

All BEMO standing seam roof profiles are suitable for subsequent curving. The functional safety of the products remains guaranteed even when curved. To ensure tolerance compensation, we recommend the installation of BEMO substructure systems BEMO-DOME or BEMO-FLEX. A 3D survey of the building form in its as-built condition is recommended, as is the use of BEMO’s 3D execution design.

Let the sun in and make your roof transparent with monoSKY®

Roof system with transparent layer and free design

The roof system is mounted on brackets as a proven standing seam roof. The transparent layer is inserted into the standing seam roof profiles from above and fastened without penetration using a special mounting rail. So, you can design your roof transparently and cleverly hide the fitting – for every shape of building.

The entire structure is transparent to a light spectrum of wavelengths between 435 nm and 660 nm, which are necessary for plant growth.

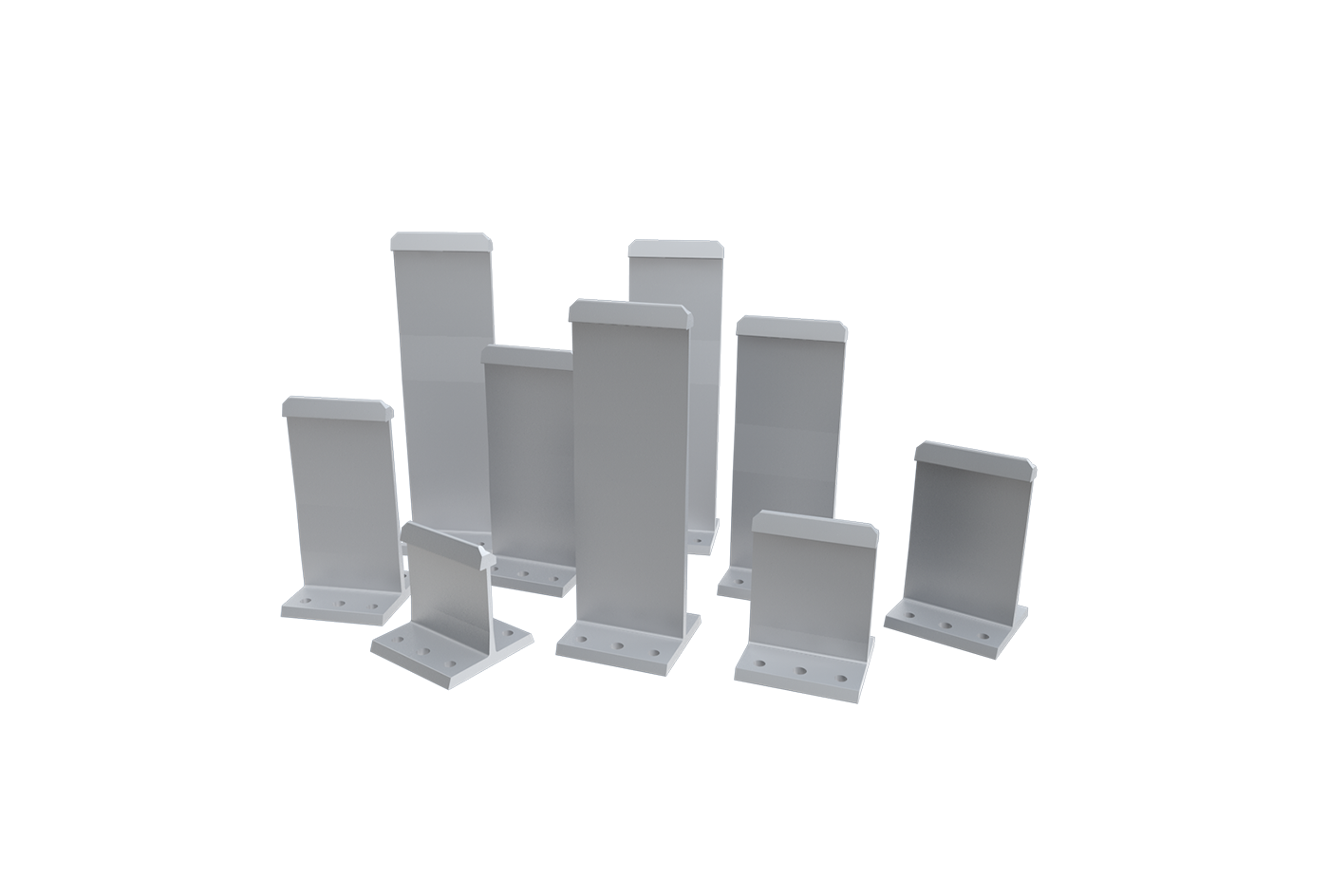

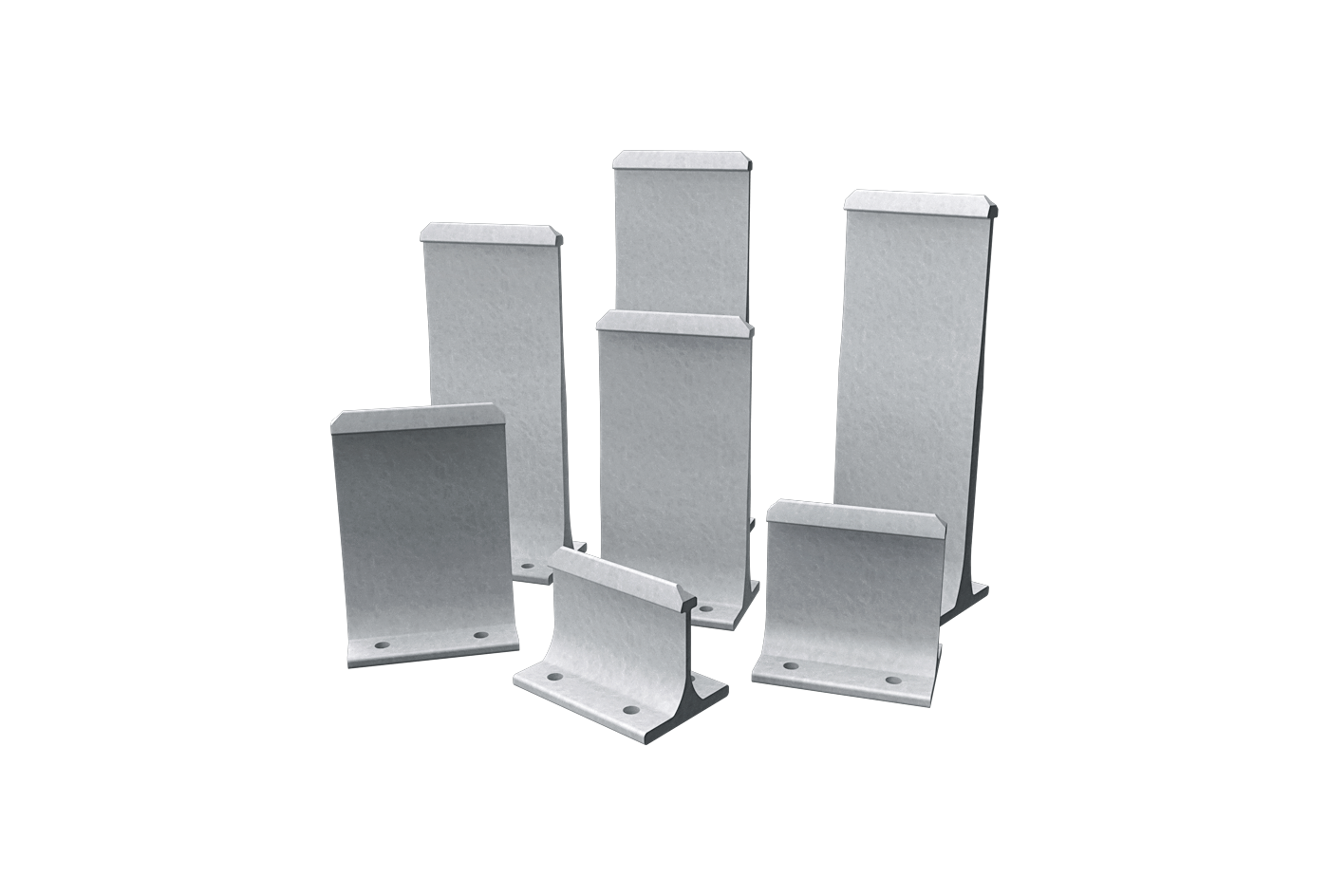

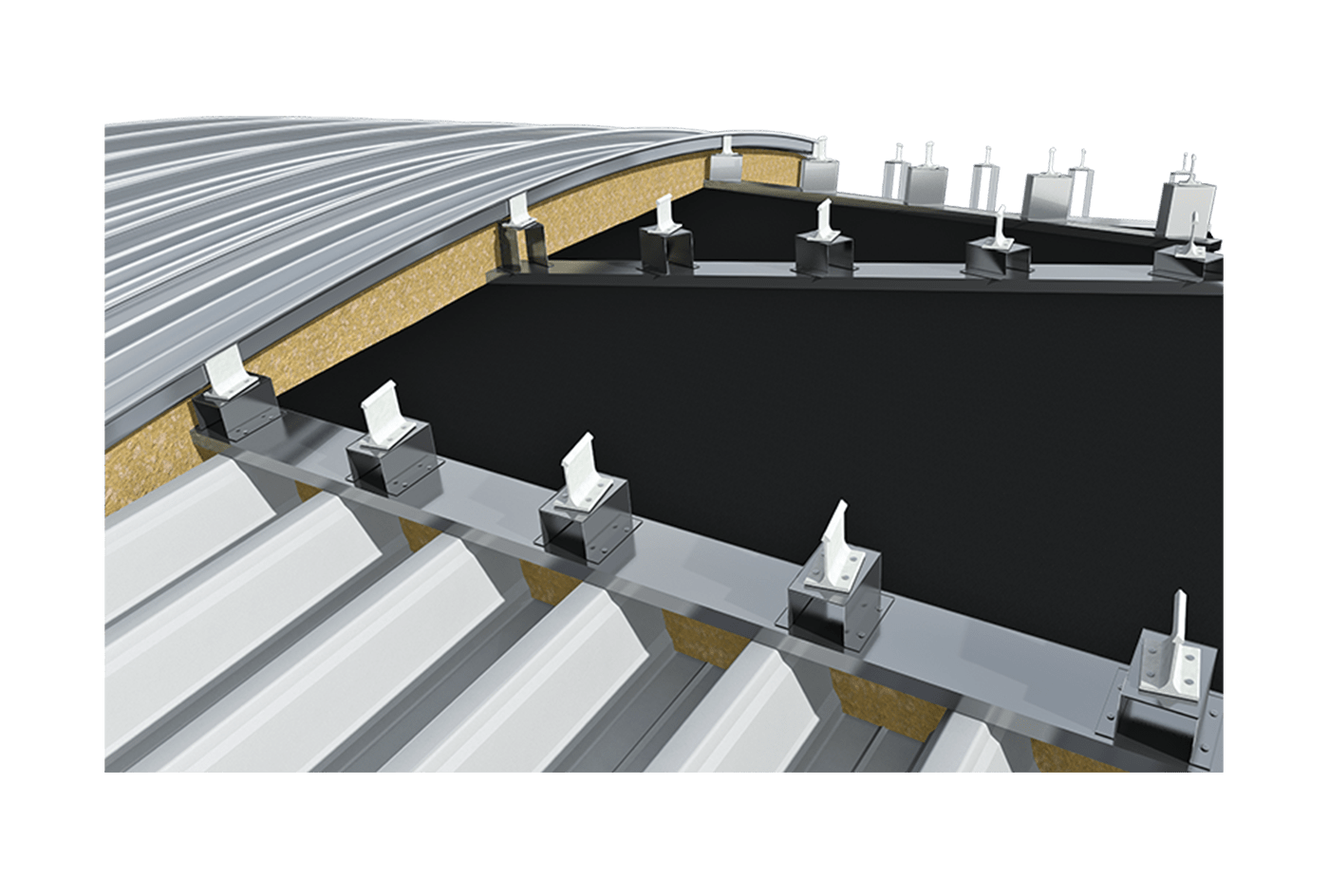

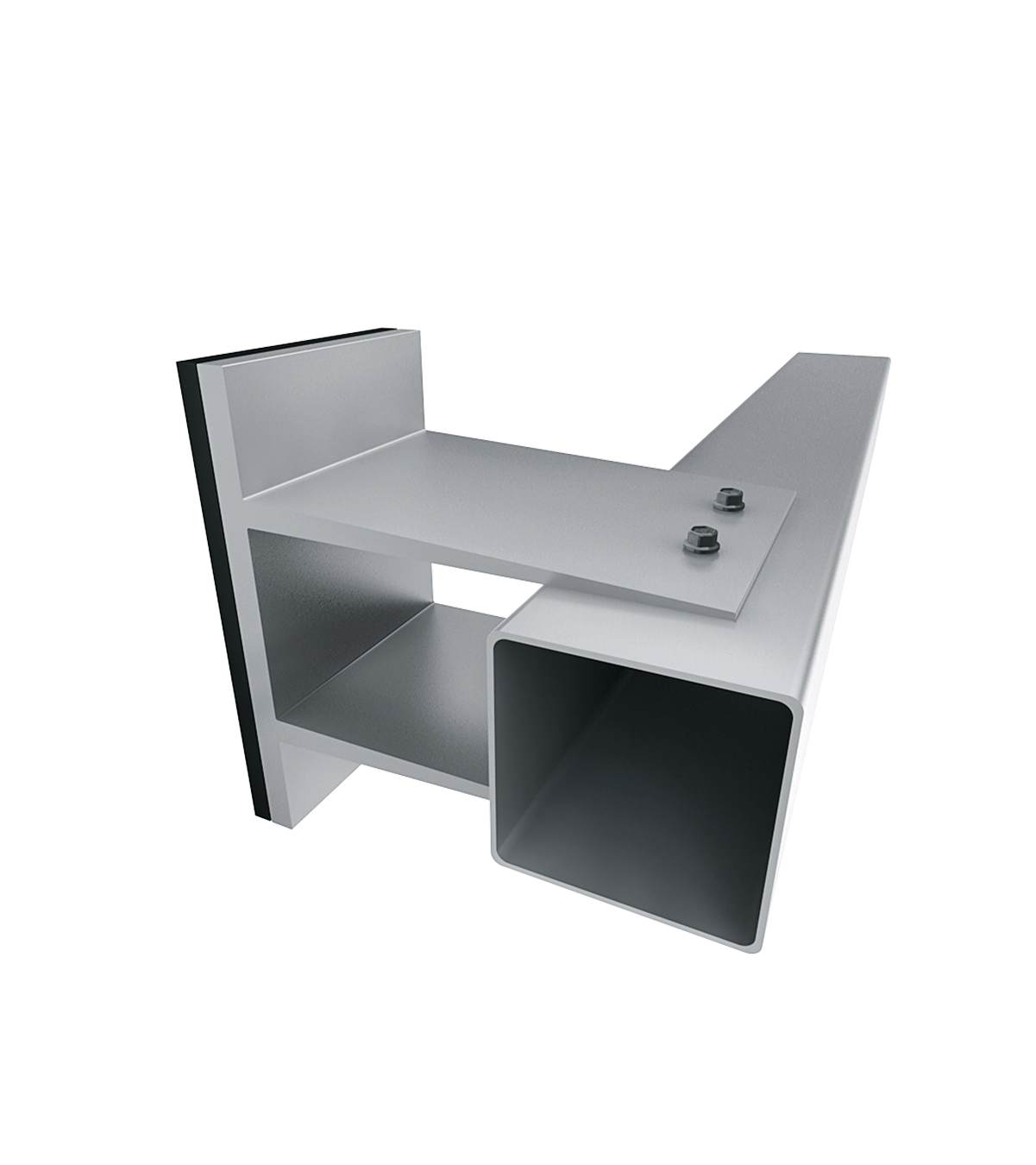

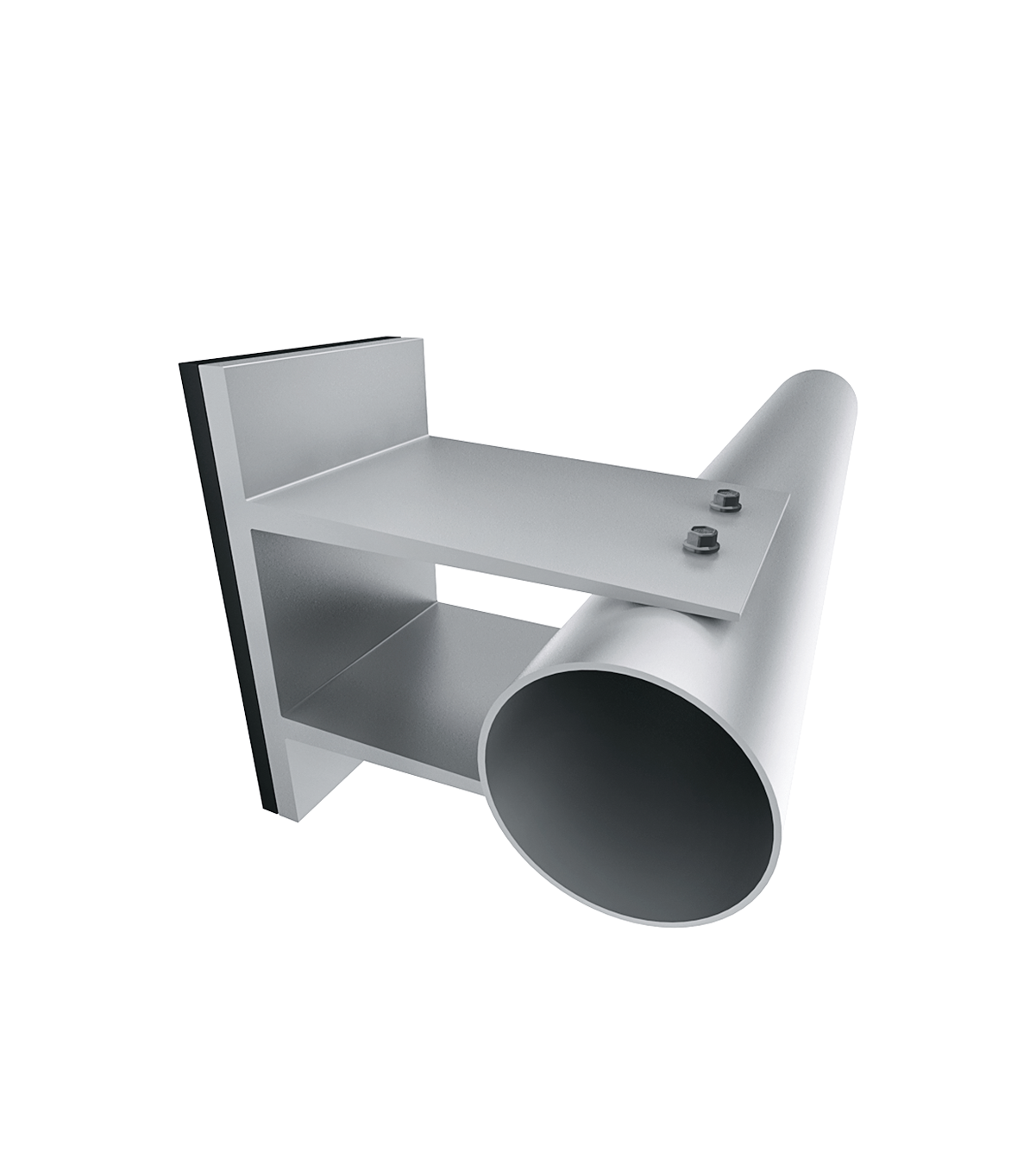

Support systems for standing seam roofs – free of thermal bridges, optimum sliding behaviour, high load-bearing capacity

High load-bearing capacity for the roof with aluminium or GFRP brackets

One of the most important characteristics of a BEMO standing seam roof is the free sliding movement of the standing seam panels during thermal linear expansion. For this purpose, the roof needs halters that ensure optimum load-bearing capacity. BEMO aluminium brackets are specially designed for optimum sliding behaviour due to their chamfered corners. BEMO thermal caps TK 5 and TK 15, which are attached to the base of the bracket, provide thermal decoupling.

Thermal bridge-free for the roof bracket in fibreglass-reinforced plastic (GFRP)

For a thermal bridge-free structure that sustainably reduces energy costs

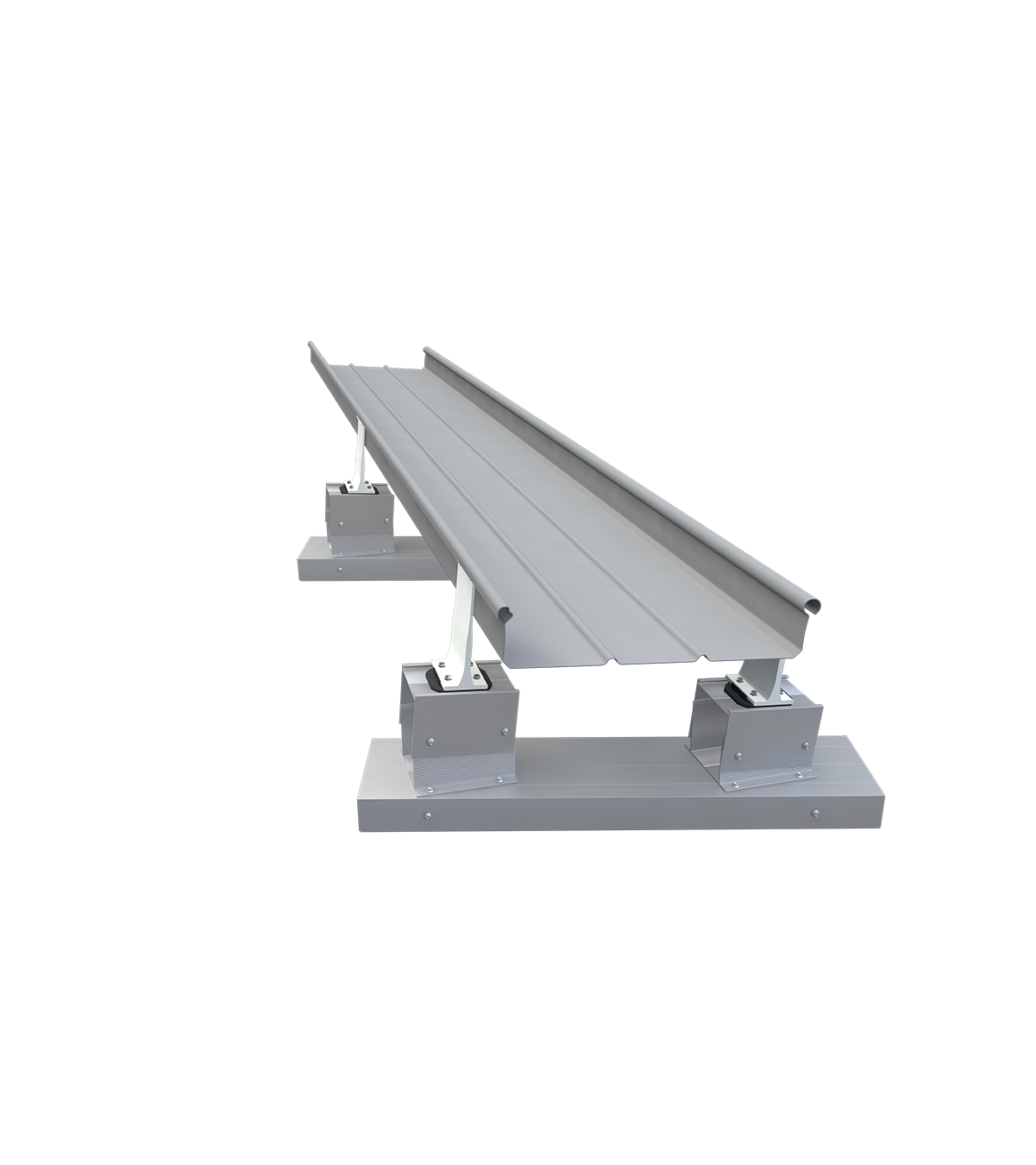

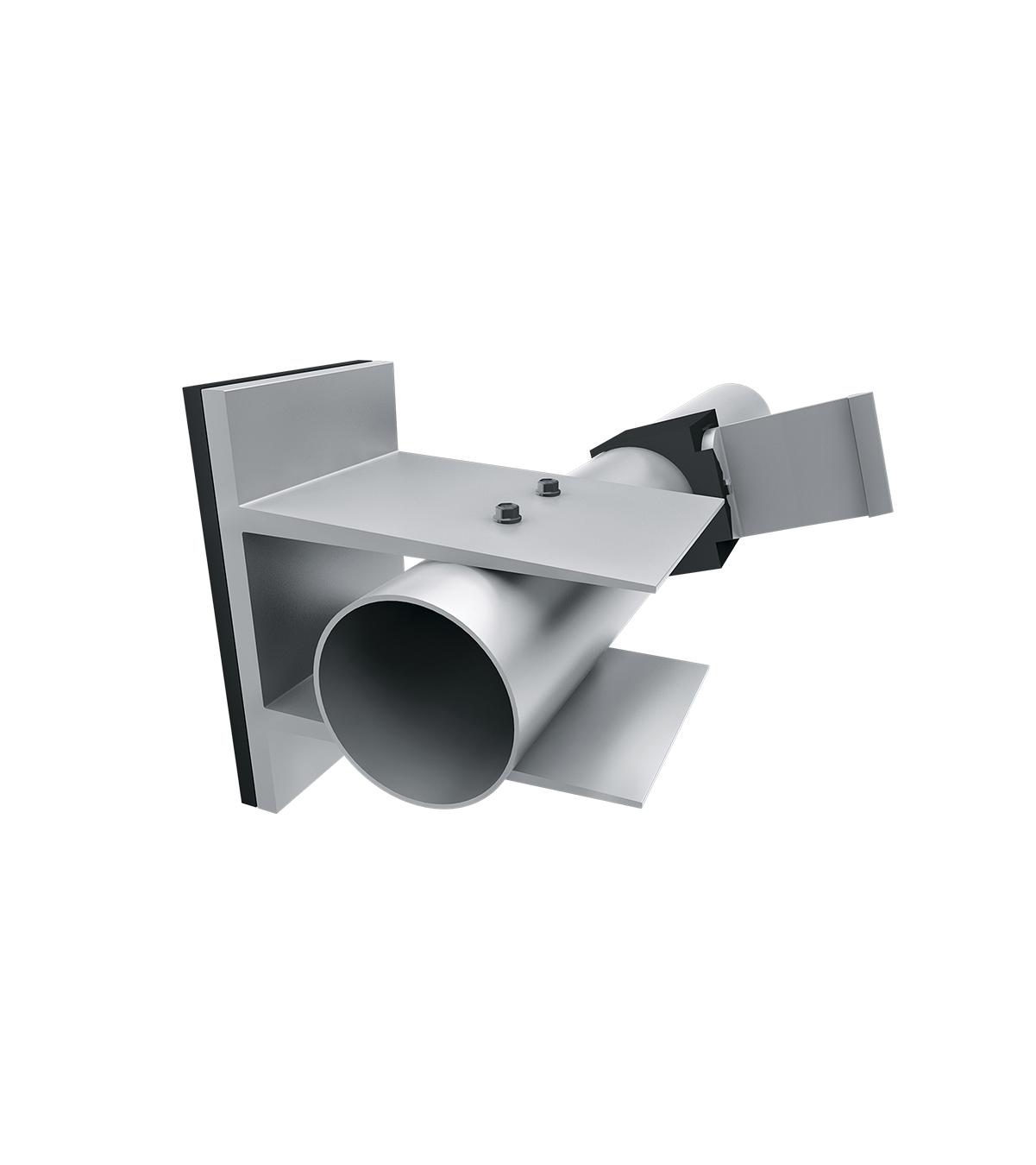

Level any substrate with the BEMO substructure

Ideal solution for uneven surfaces and curves

The 2-part BEMO substructure is the perfect solution for standing seam roof installations on uneven substrates such as concrete ceilings or old supporting structures. Here, a base profile with the geometry of a hat or U-profile is fitted. A 2nd, adjustable profile is mounted on it. Tolerances of several centimetres can easily be compensated and adjusted by changing the height. The upper profile can also be supplied pre-assembled with BEMO brackets for quick and economical installation. Besides the uneven substrates, the solution is also ideal for curves that need to be created with parallel crowned panels.

A 3D scan of the assembled lower base profiles and an evaluation of the scan data by the BEMO 3D service is recommended. As a result, you get an exact design of the necessary installation position of the upper profiles. The upper profiles can be precisely pre-assembled in the workshop.

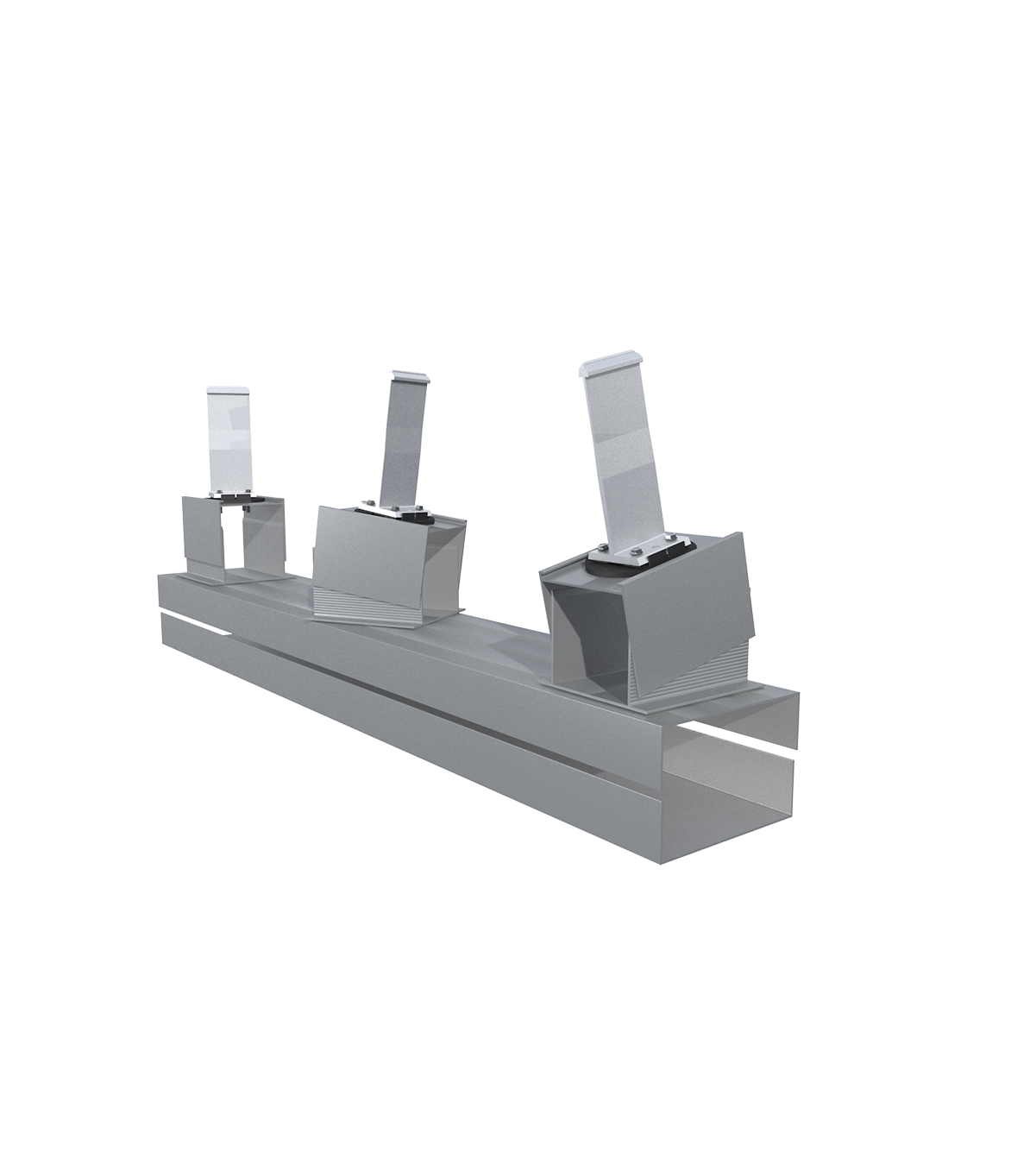

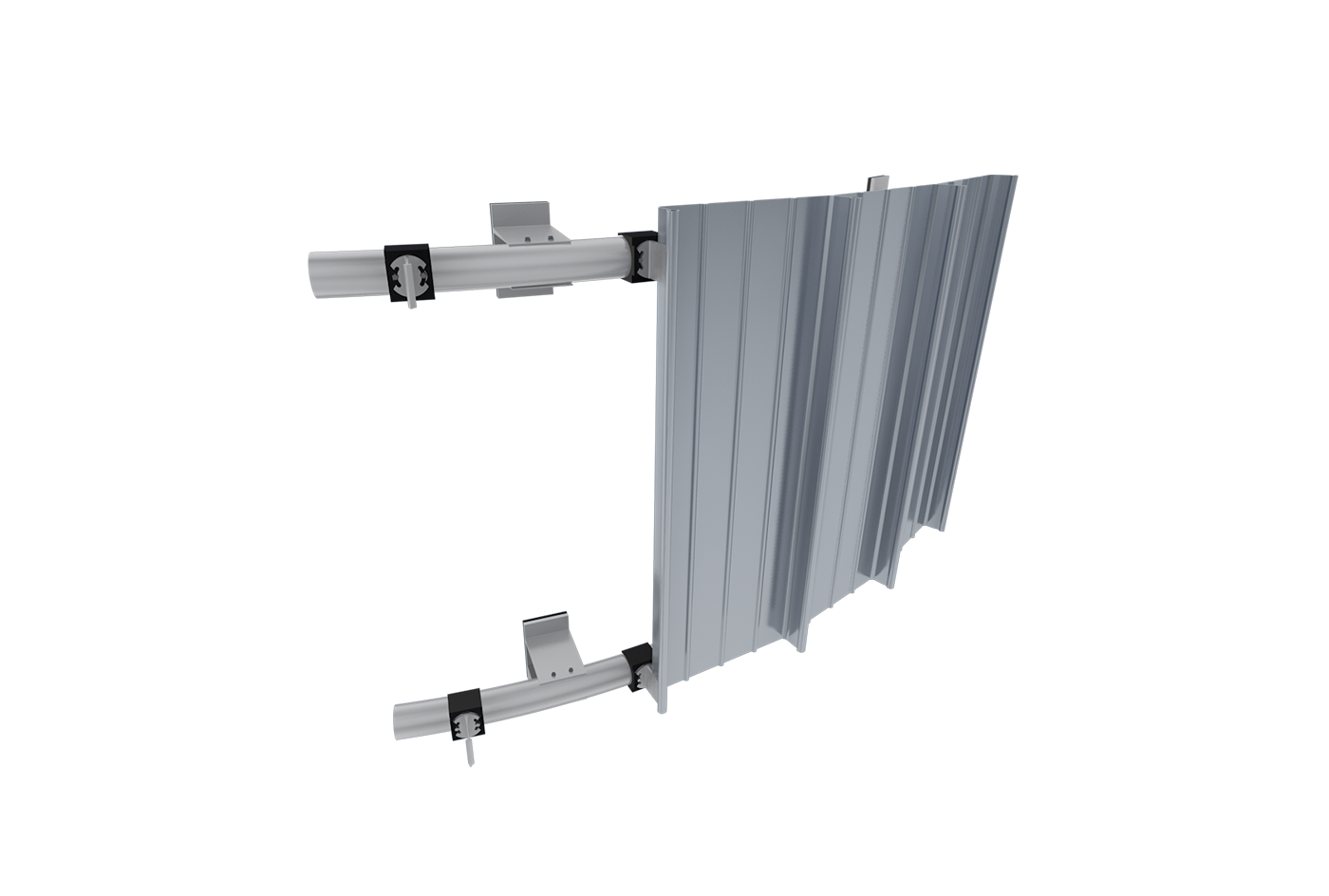

Roof substructures from BEMO for high-quality building envelopes

BEMO-FLEX substructure for precisely fitting roofing and easy installation

The combination of modern computational design methodology with a survey of the existing structure makes BEMO-FLEX easy to use everywhere and for all our cladding profiles in roofs and façades – also for standing seam roofs. The lower U-profiles of the FLEX-SYSTEM are mounted according to static specifications. The mounting position of the U-profiles is captured in a 3D scan. From this, we derive the necessary position and height of each BEMO halter. The upper U-rail is then pre-assembled in the workshop together with the positioning brackets and bolted to the lower U-rail in a final work step to complete the standing seam roof substructure.

Designing the roof substructure appropriately allows even very high tolerances to be compensated or new building shapes to be designed.

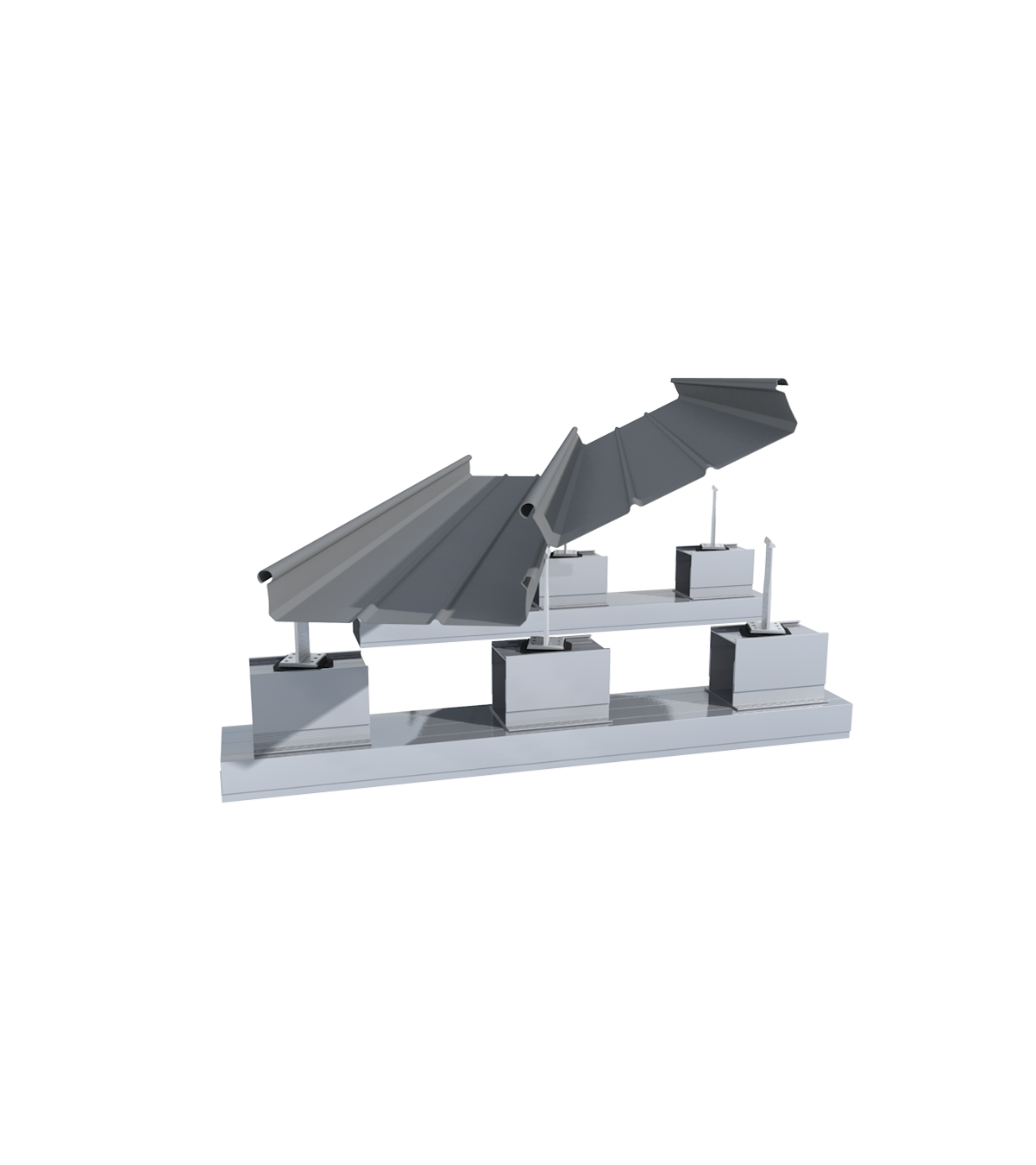

BEMO-DOME as substructure for curved buildings

The BEMO-DOME substructure offers the right, highly flexible substructure solution for cylindrical building shapes or those curved in two axes. BEMO-DOME is primarily used for the façades of stadiums, silo buildings, oval towers (such as digesters) or in the transition area between roofs and façades. Whether for a rear-ventilated or non-ventilated wall structure, BEMO-DOME meets all requirements.

We recommend the use of a 3D scan as an on-site survey and BEMO execution design in 3D for this substructure system to obtain a perfect surface of the metal profiles. As a result, you get a grid design with proposed mounting points and their distance and positions from the supporting structure.

Inspiration

Casals Forum, Kronberg Academy

Trabzon Bus Terminal

Aviva Studios (Factory International)

Knutwil depot and fire brigade

Sagi Centre

360° Service

BEMO stands for passion and enjoyment of challenges. In every project and beyond.

BEMO stands for a lot – but above all for passion and joy in every project. No matter what challenge may arise. Rather, we respond to this with new ideas and therefore create individual projects with unique standing seam roof systems. And that from the first moment: We are at your side as experienced project consultants from the conception phase. We are your partner for all system-relevant questions in the planning phase and take responsibility so that your standing seam roof is in professional hands. This may also include measurements on site. All-round service not only means planning and security for you, but also for us. To give you the best service, your project benefits from our global network and international experience, especially when it comes to delivery logistics and material provision.

BEMO stands for teamwork and trustworthy partnership with 360 ° service in every respect.

We promise.