Perforated façades

Playing with light and shadow

The areas of application and design options for our perforated façade products are almost unlimited – they are suitable for exciting shapes or energy-saving shading solutions on external façades, for unusual lighting effects or acoustic measures within buildings. The profile variants are ideally suited for individual and unique design options both indoors and outdoors.

Façades with perforated profiles change with the incidence of light, the position of the sun or special lighting. Built in lighting as a stylistic device can also highlight the characteristics of your transparent façade. There are hardly any limits to façade design with BEMO – develop your unique façade together with us.

-

Large selection of perforations

for standing seam and profile façades, façade panels and composite panel façades -

Countless design options

for material, colour, profile geometry and hole pattern -

Suitable for interior and exterior use

e.g. as an acoustic measure or shading element -

Quick and easy installation

of all perforated façade solutions

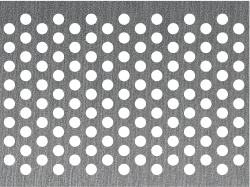

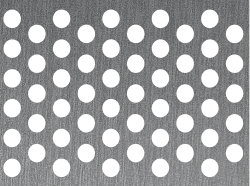

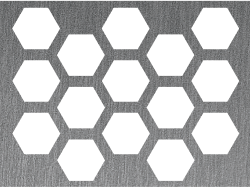

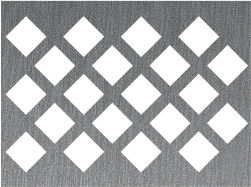

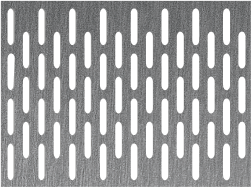

Examples of hole patterns:

The standing seam façade from BEMO makes smooth transitions and free forms possible

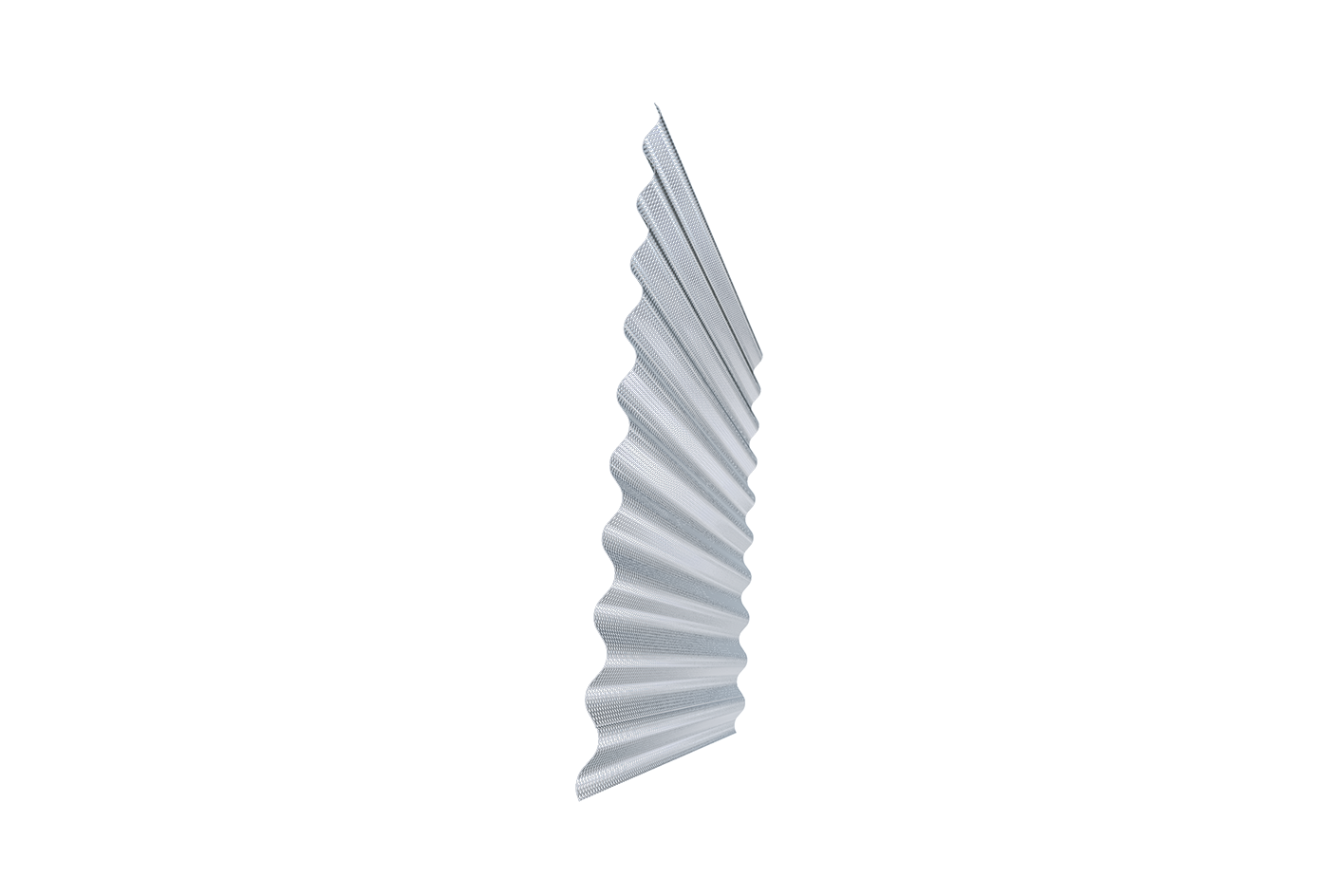

Straight or conical - Free choice of shape and material for perforated façades

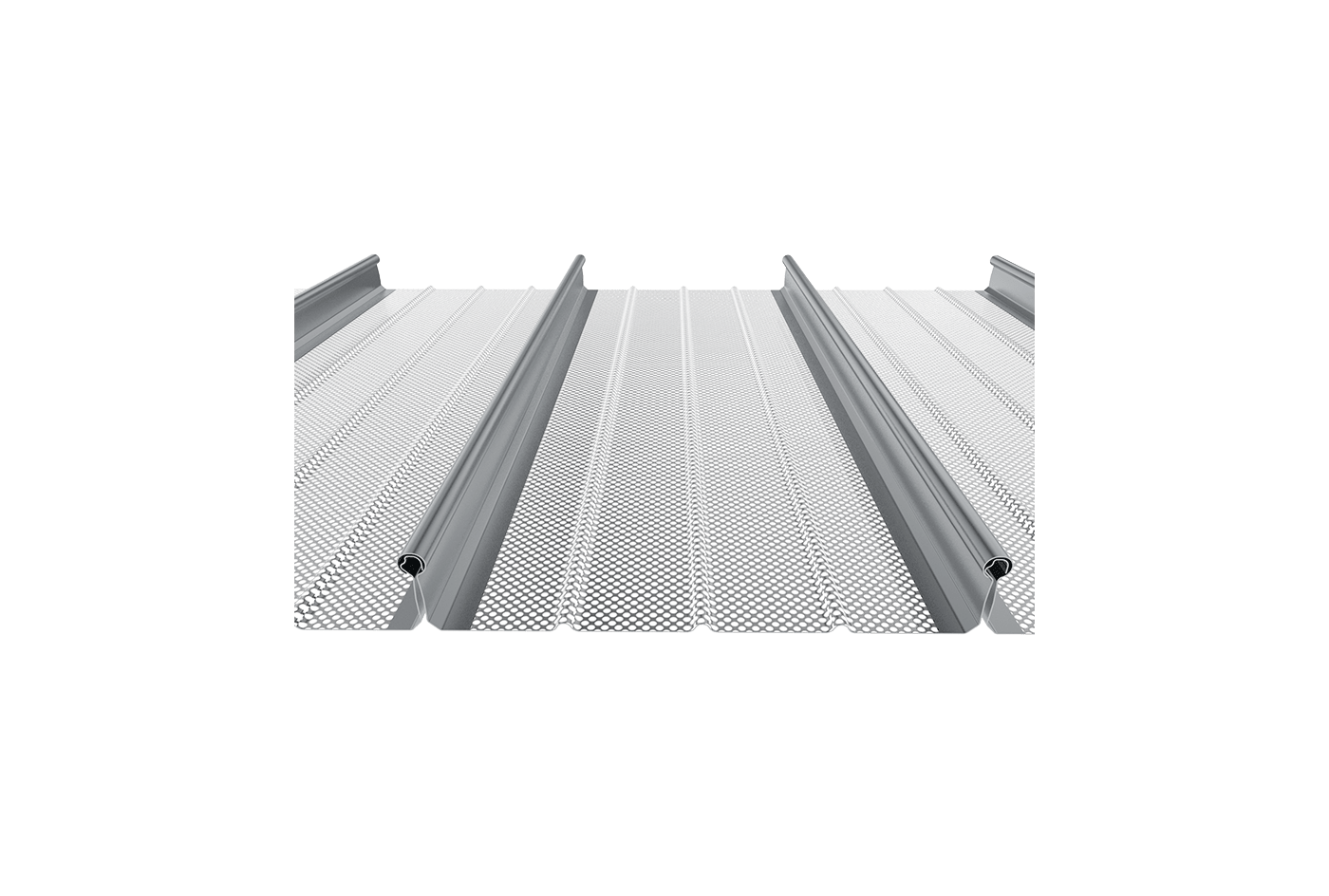

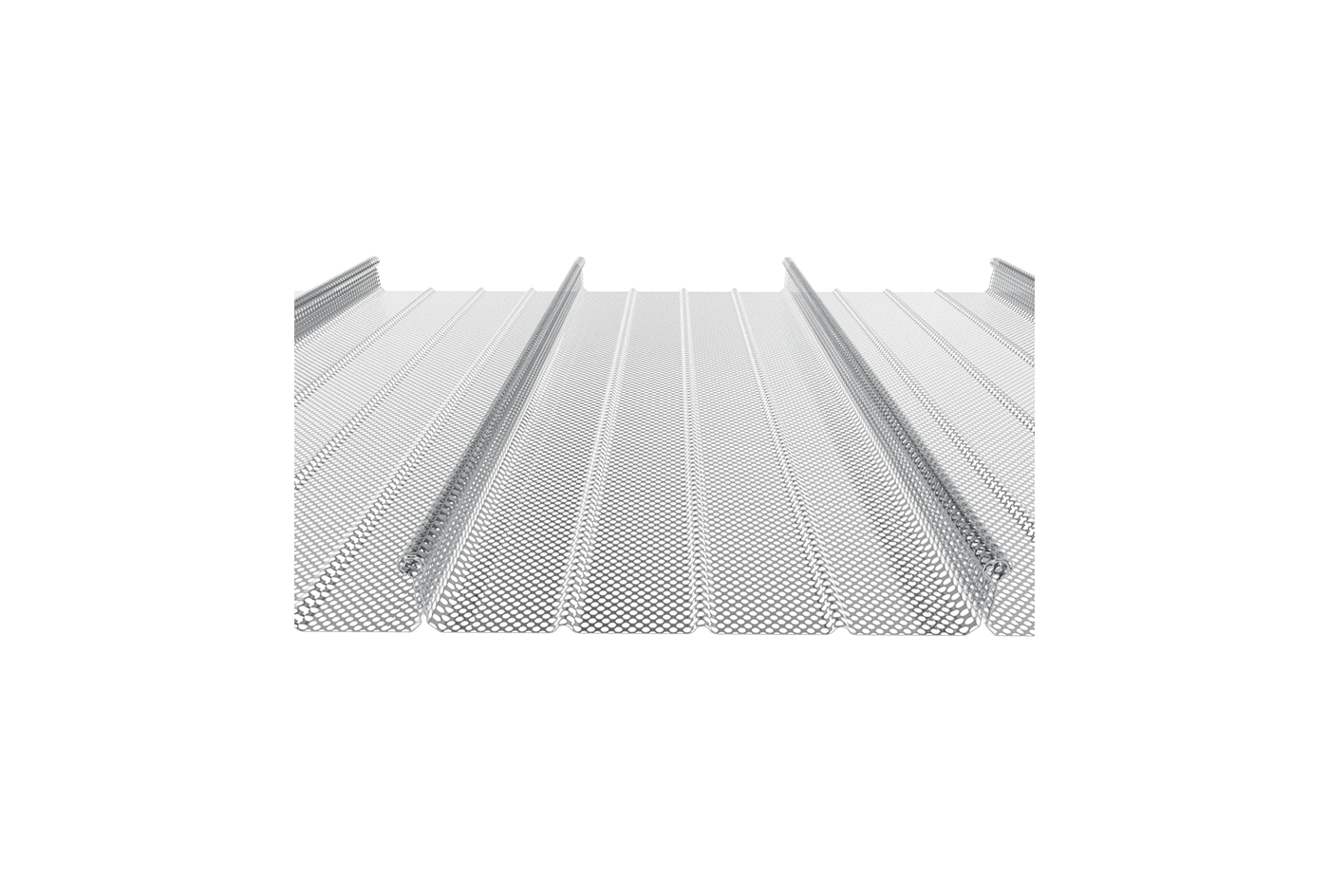

For the perforated façade large spans can be bridged easily with standing seam profiles. The variety of possible combinations is almost limitless. Thereby the profiles widths, the material thickness, the web heights, and the hole pattern influence the load-bearing capacity and the possible span. Thanks to the availability of flexible combinations, perforated standing seam profiles offer maximum freedom when designing the façade.

Perforated façades with BEMO standing seam profiles are perfect for the front of car parks. Standing seam profiles are only attached between floors. Then they easily span a vertical distance of up to 2.80 m. Pre-assembled and adjustable substructure systems complement the perforated standing seam profiles ideally – easy, quick, and economical. A great advantage: Perforated profiles have a positive influence on fire protection in multi-storey buildings thanks to the high smoke extraction option. In addition, fully insulated cassette solutions including a perforated inner shell can contribute to the acoustics in a car park.

Perforation with unperforated web | Full-surface perforation for conical and MONRO sheets

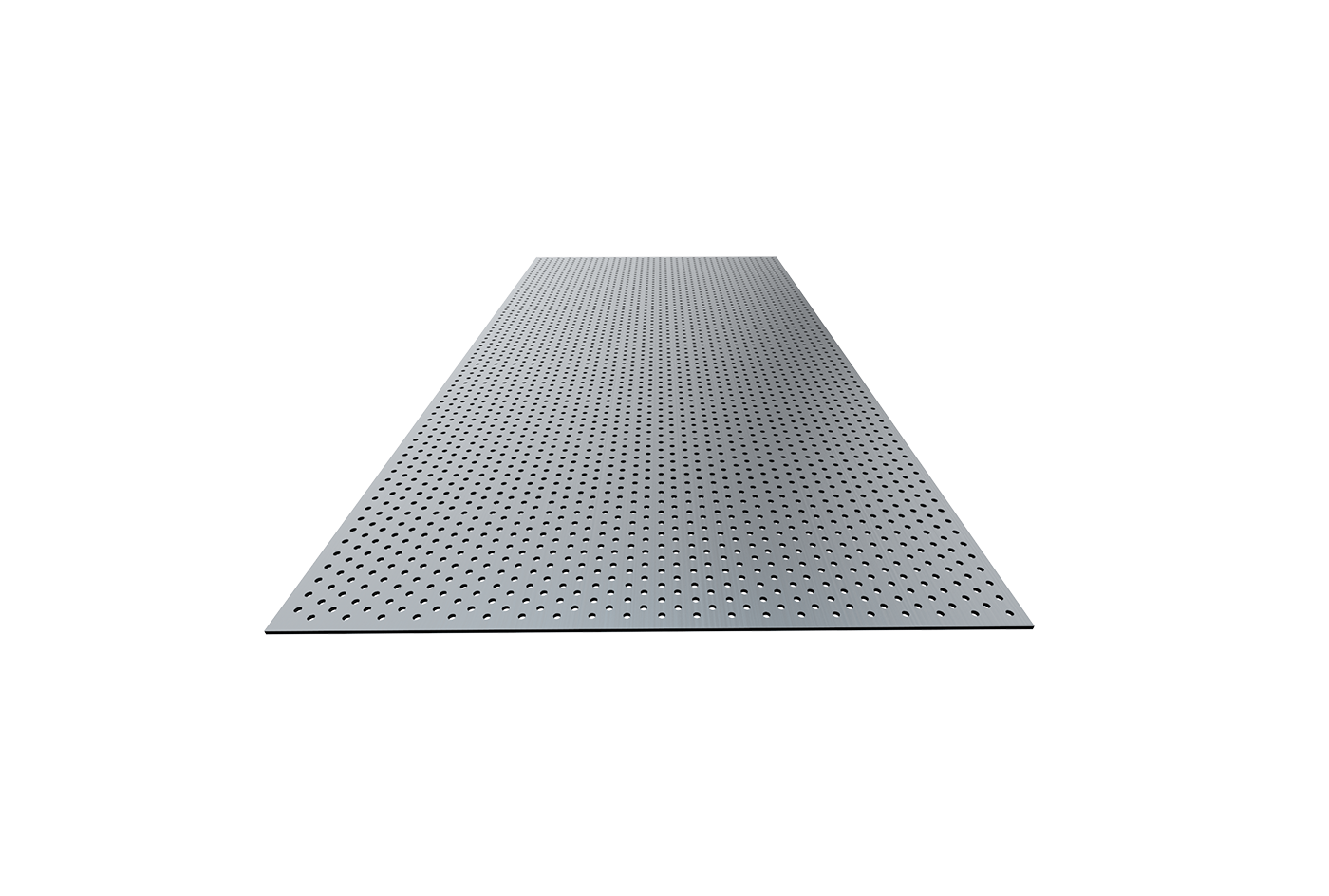

Perforated aluminum composite panels

Almost limitless variety of designs with BEMO-BOND

With the aluminum composite panels BEMO-BOND a wide variety of designs as high-quality façade cladding for curtain-type, rear-ventilated façades is possible. Whether visibly or invisibly attached, they are freely configurable, in different panel dimensions of 6,000mm x 2,000mm and with a wide variety of colours and individually designed detail solutions.

The design options with BEMO-BOND aluminum composite panels are almost limitless: Perforated, backlit elements if required, the possibility of integrating lettering, or coats of arms or logos. Also as a non-flammable composite panel in building material classification A2.

In-house individually manufactured aluminium composite panels

The processing of the aluminum composite panels takes place in our own processing centre. The preparation is based on the BEMO implementation planning. Therefore, the panels are pre-processed according to all requirements and delivered to the project just-in-time. The fire classifications include B-S1, dO and A2-S1, dO. The plate thickness can be 4 mm or 6 mm.

Perforated profile façades

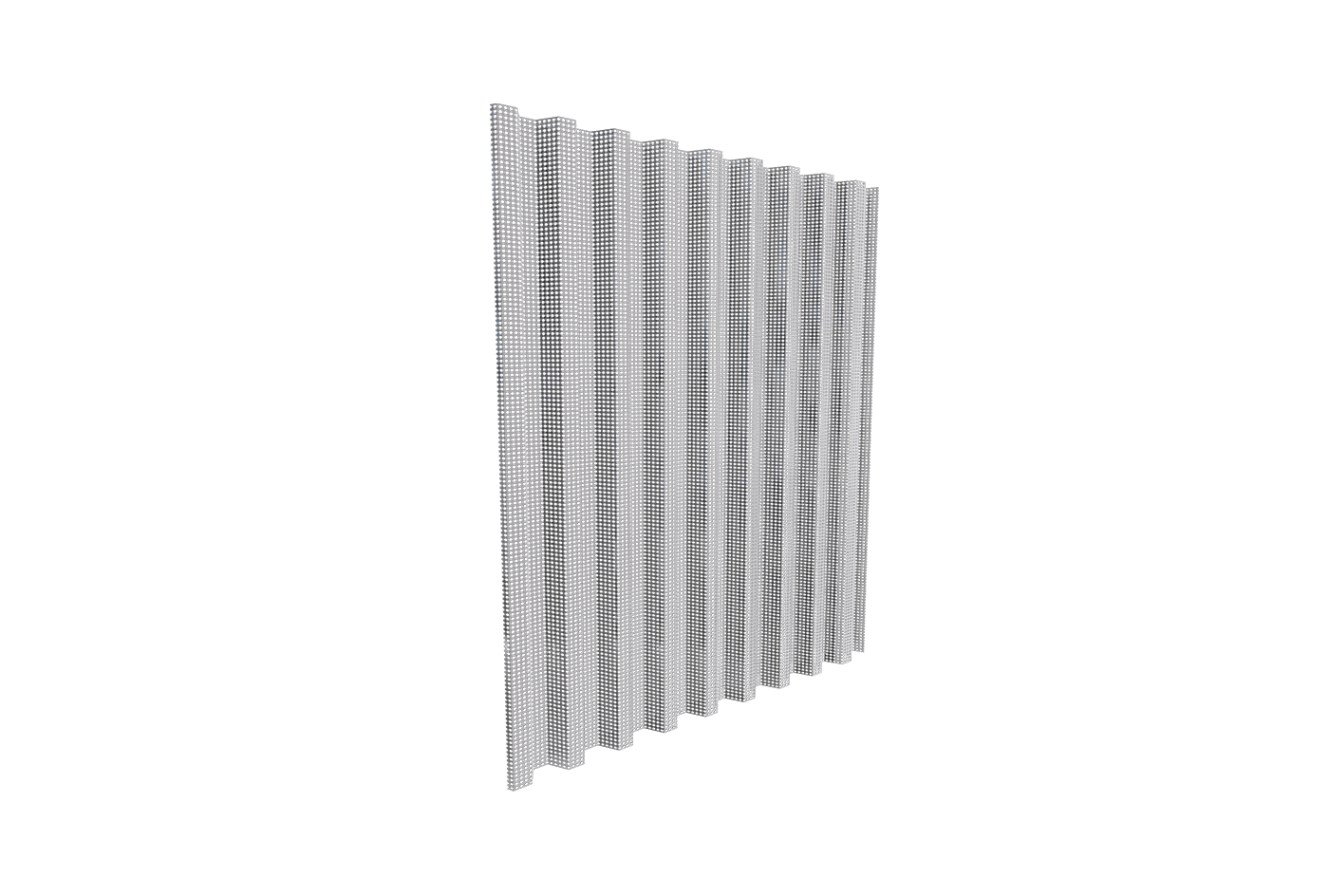

Façades with perforated trapezoidal and corrugated profiles

The BEMO trapezoidal profiles are also suitable for cladding cassette systems. Moreover, they can be used for direct assembly on the substructure in cold halls or as cladding for curtain-type, rear-ventilated façades. BEMO trapezoidal profiles represent a particularly economical façade system. Depending on the profile geometry, large distances can be achieved between the necessary fastening points. As a result, the work involved in the substructure is reduced. The different profile geometries offer many design variants. Evenly profiled geometries look harmonious from a distance whileunevenly profiled ones increase the surface effect.

Perforated façades with substructure system

To compensate for tolerances and to avoid thermal bridges

With the substructure the connection between the load-bearing wall and façade cladding is created. Thanks to its anchoring in the outer wall, the façades cladding weight lies on the structure of the building. We offer innovative substructure systems constructed for VHF façades that compensate for tolerances and are free of thermal bridges.

Considering all the circumstances and regarding which substructure fits which requirements, we would be happy to work out individual solutions in cooperation with you.

Inspiration

3 Sisters Reeseberg

Eislingen gym

Apartment building in Münchenstein

Elementary school Längenfeldgasse Vienna

Deggendorf river management office

360° Service

Best technical support

BEMO has its own planning office with system-experienced technicians and engineers – working with the most modern, partially self-developed, 3D planning technology. The services range from the initial consultation to the implementation of the desired design, the choice of materials and the design, the first technical details and static preliminary measurements to the complete implementation and workshop planning.

Cost estimates, technical optimizations or variant calculations help you to optimize your project economically. 3D measurements as the basis for our well thought-out and easy-to-assemble systems and implementation in 3D planning. We understand all of this by a comprehensive partnership with BEMO.