BEMO-MONRO®

A standing seam system for special building shapes

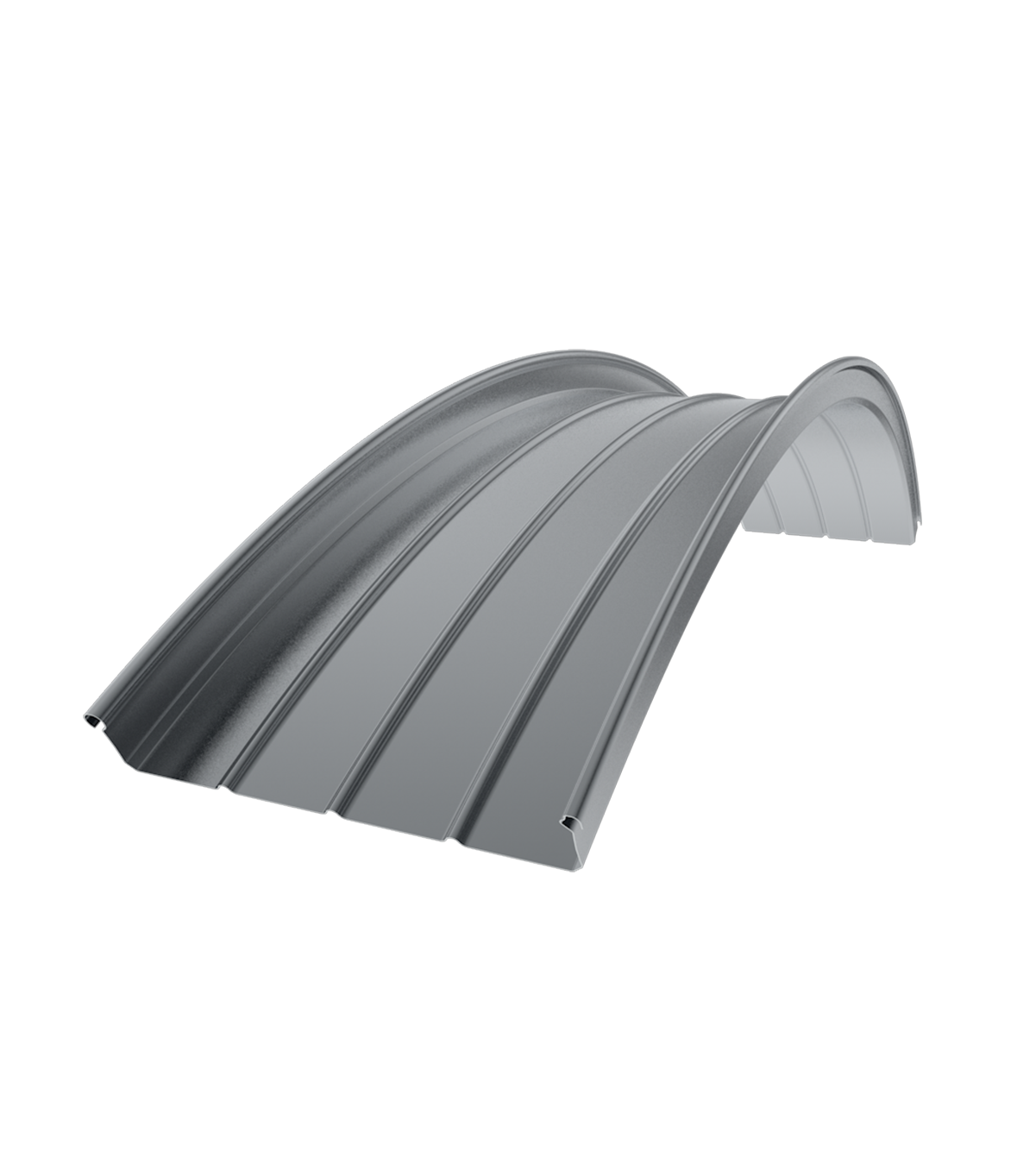

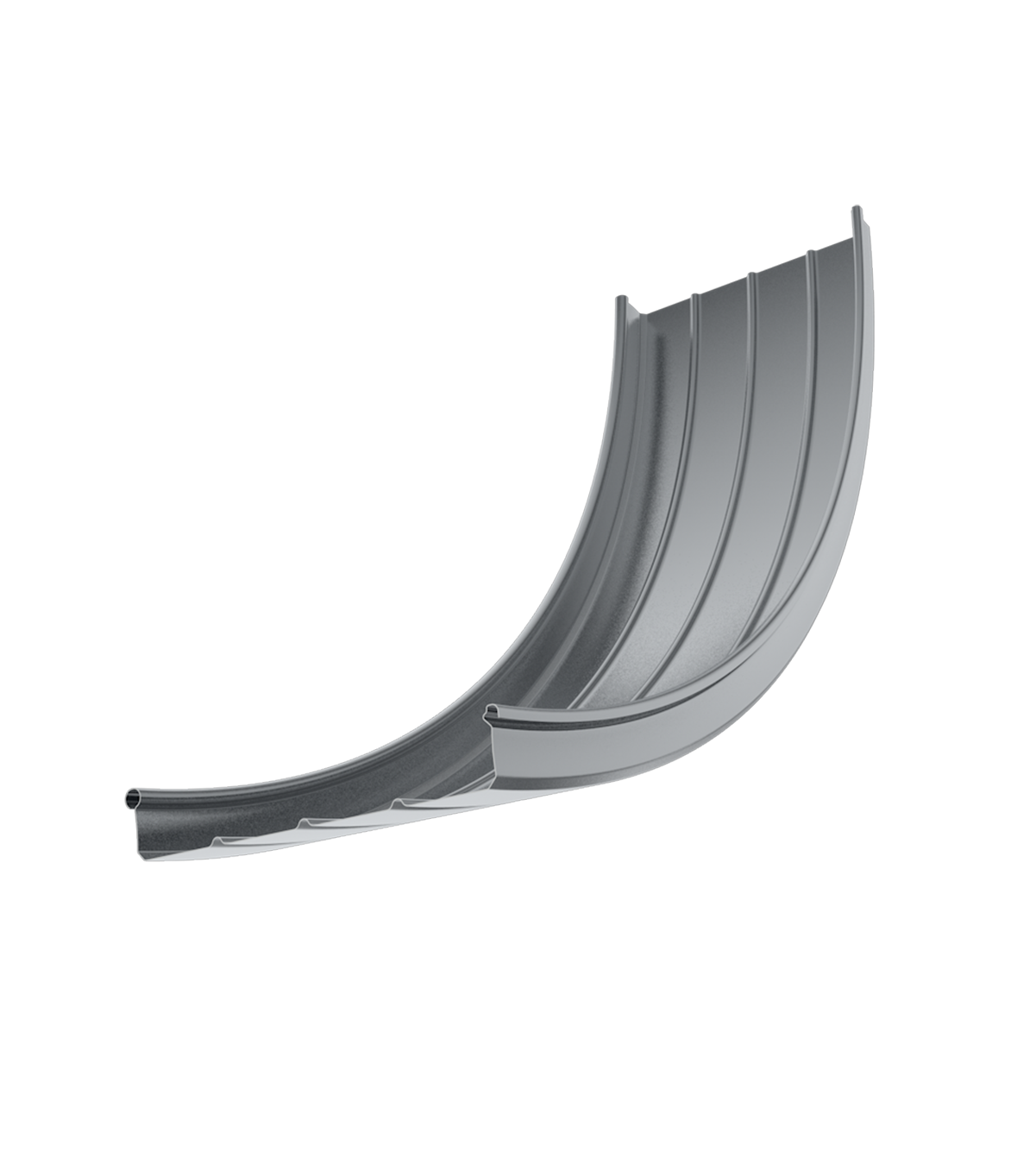

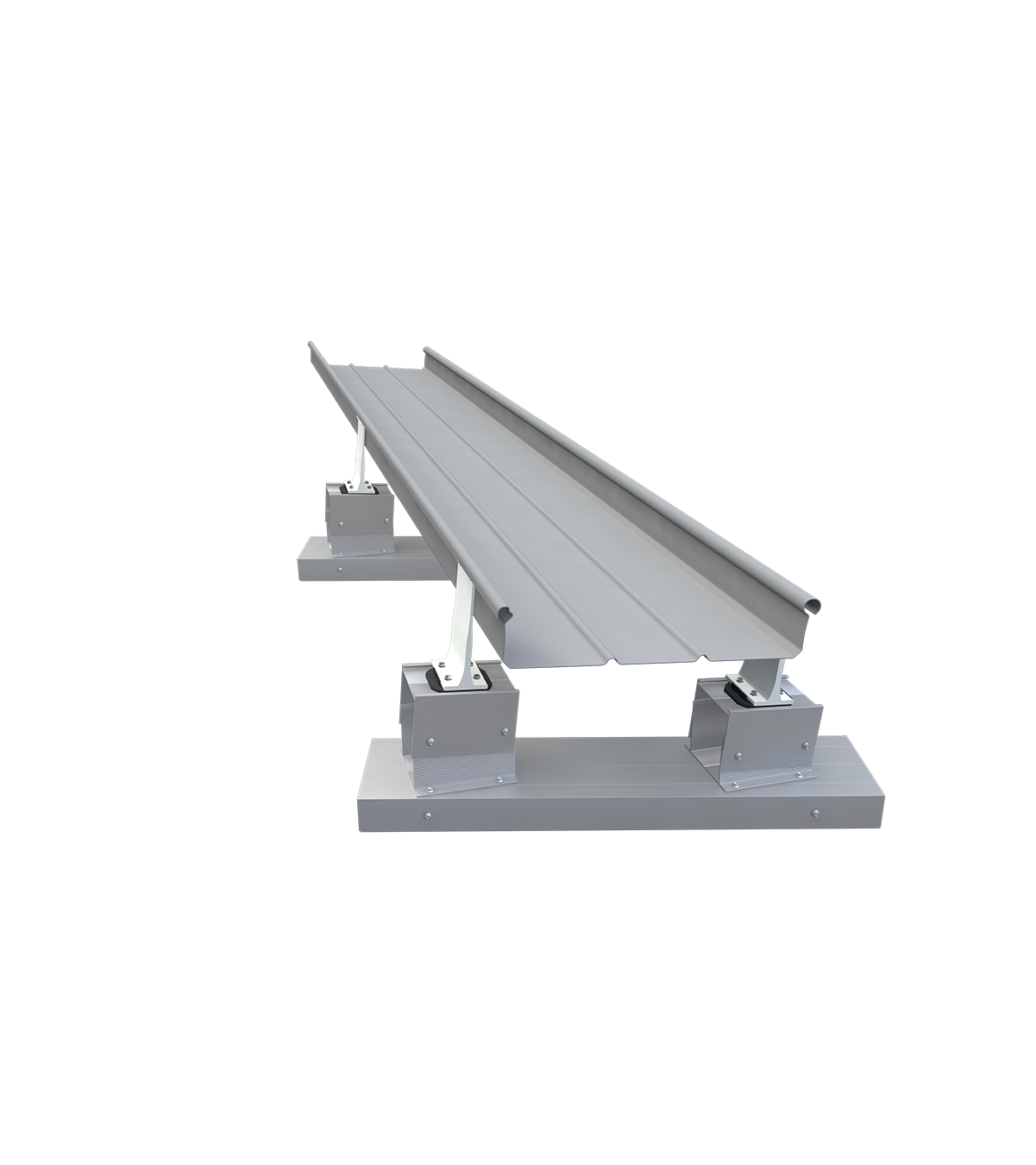

The patented BEMO-MONRO® system is BEMO’s standing seam system that stands for flexible adaptability of metal roofing to almost any building geometry. Here, each panel of a free-form building can often be unique. The metal panels are shaped a single work step with millimetre precision to suit the dimensions of the building.

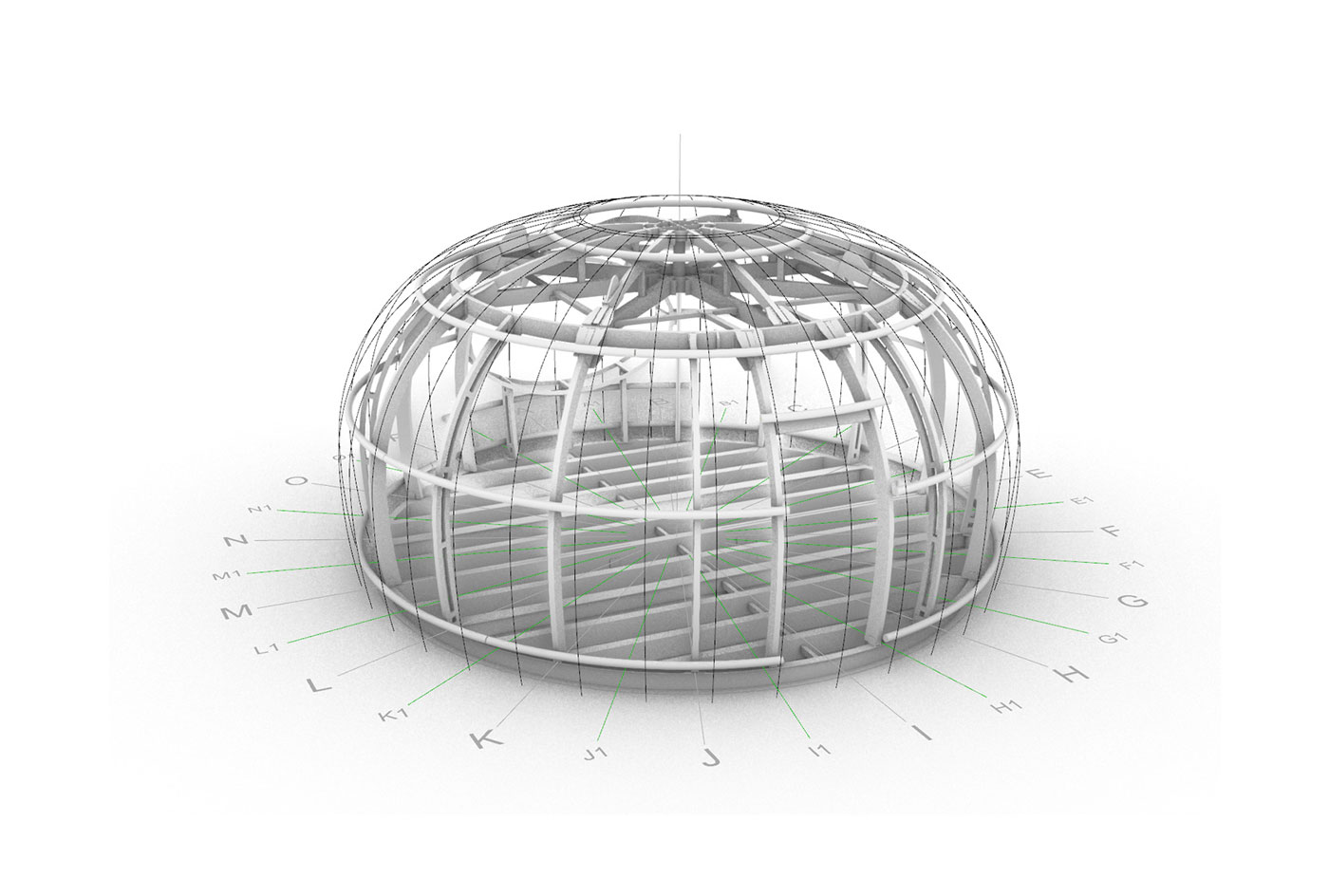

The MONRO® system is generally used in combination with a substructure that can be adjusted in three dimensions. Irregularities in the supporting structure can therefore be compensated easily and quickly. The BEMO 3D design plans the system ready for assembly.

Special conical profiles are used for larger circular and conical buildings. A minimum width of 100 mm and a maximum deck width of 800 mm allow the realisation of almost any requirement. All BEMO special profiles are also available in curved shapes and in all materials.

-

Patented BEMO-MONRO® standing seam system

can be adapted to almost any building shape -

Variable track lengths

up to more than 100 metres -

Compensation for unevenness in the supporting structure

through three-dimensionally adjustable substructure -

Millimetre-precise fit of the

of the metal tracks thanks to exact 3D dimensions

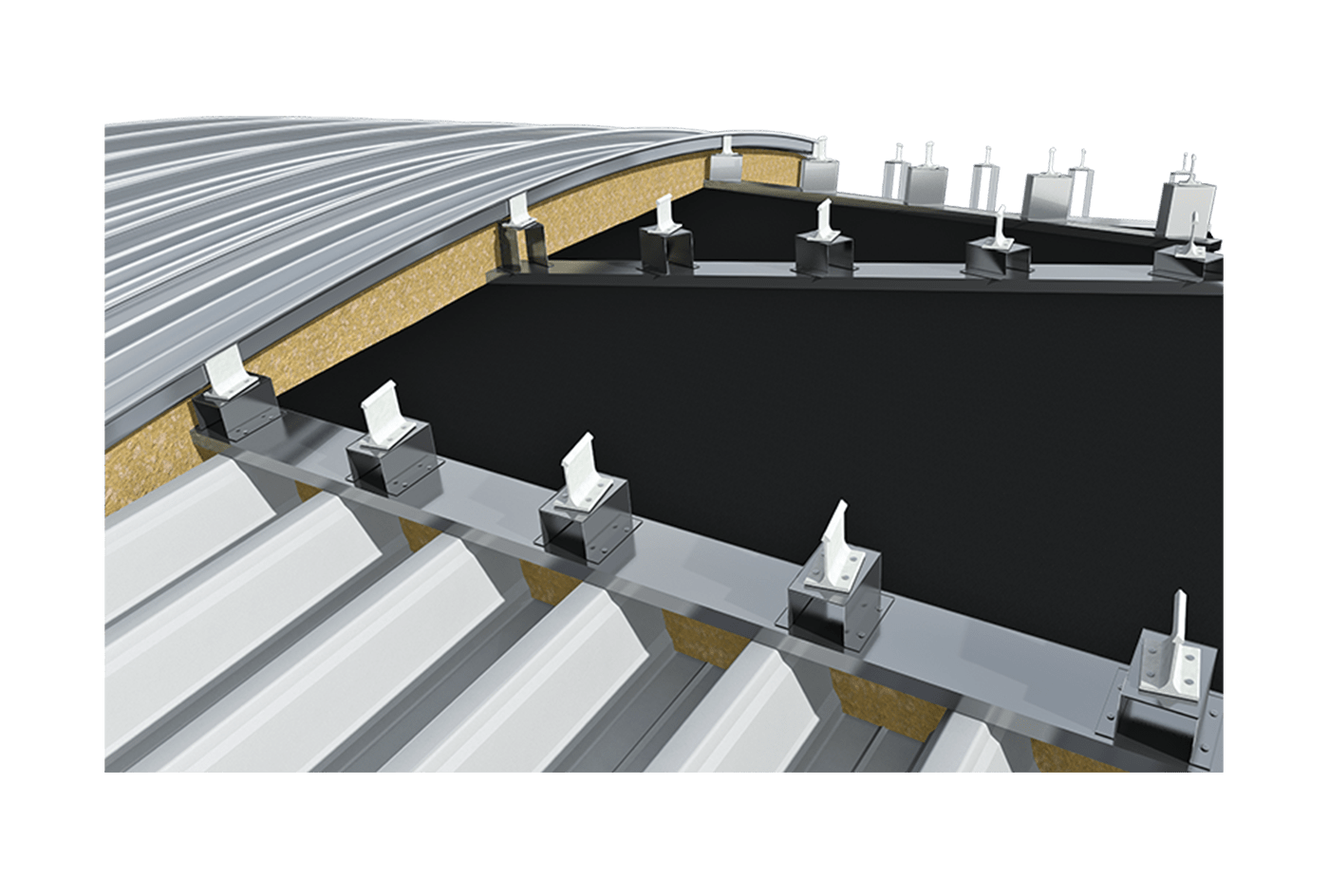

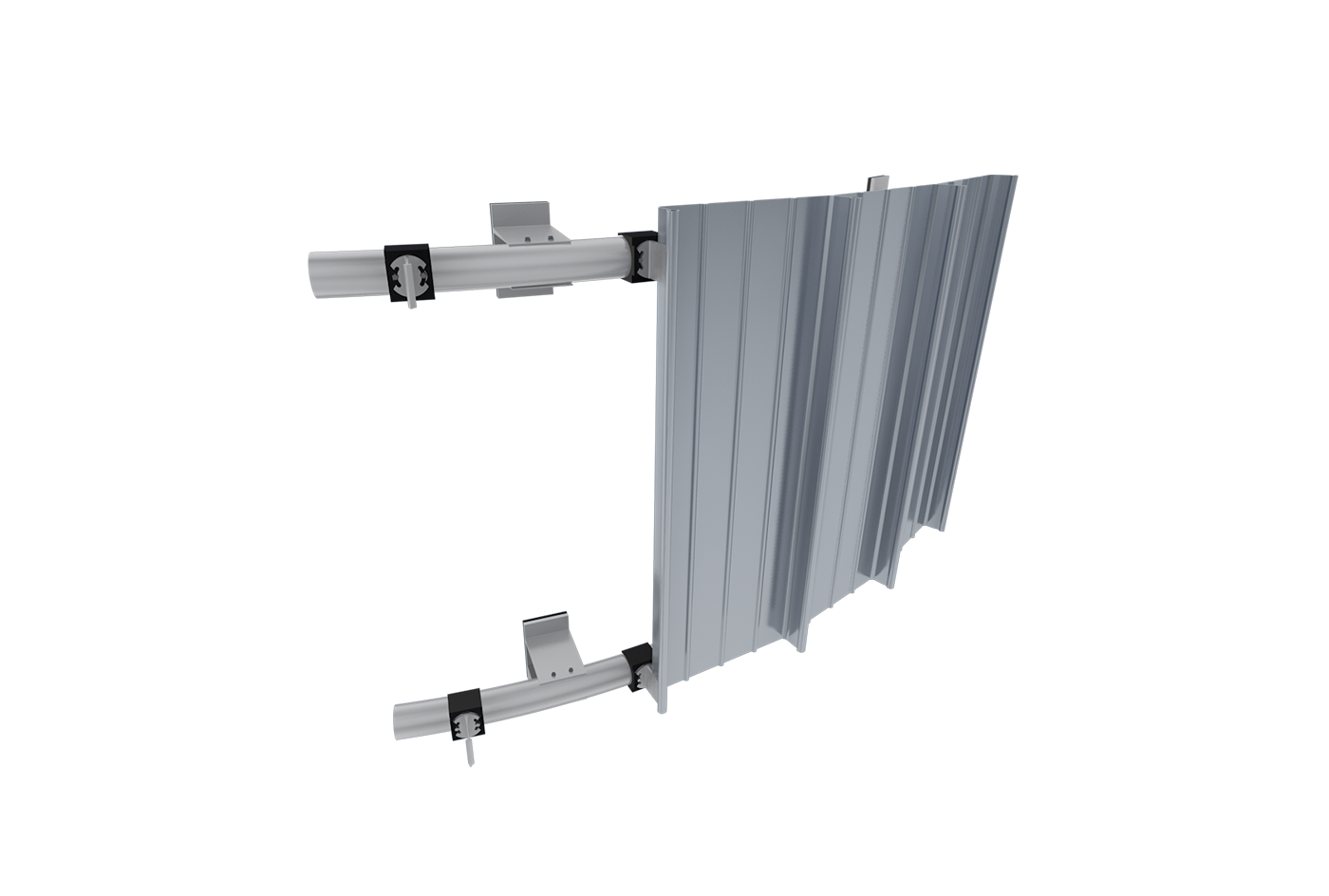

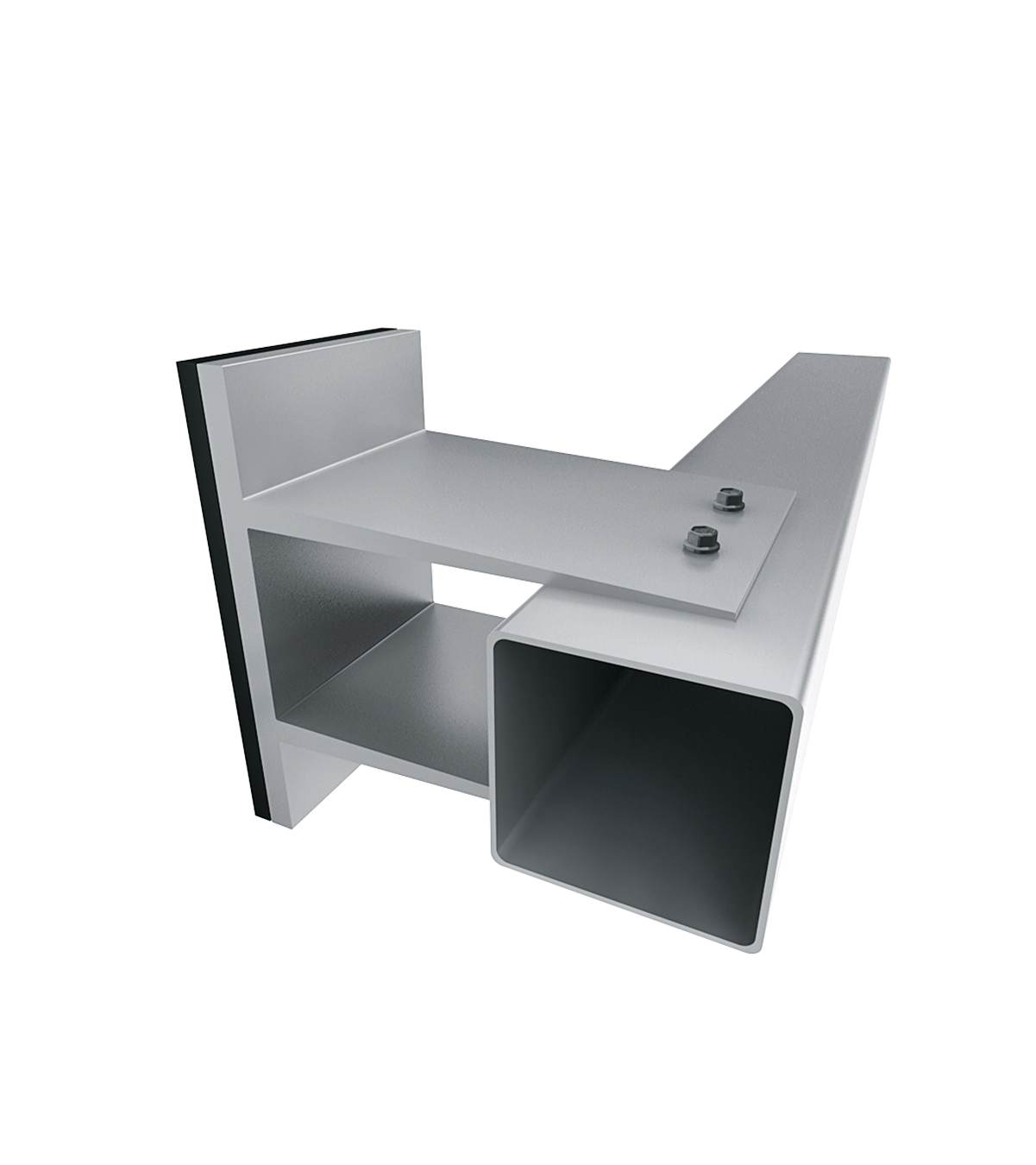

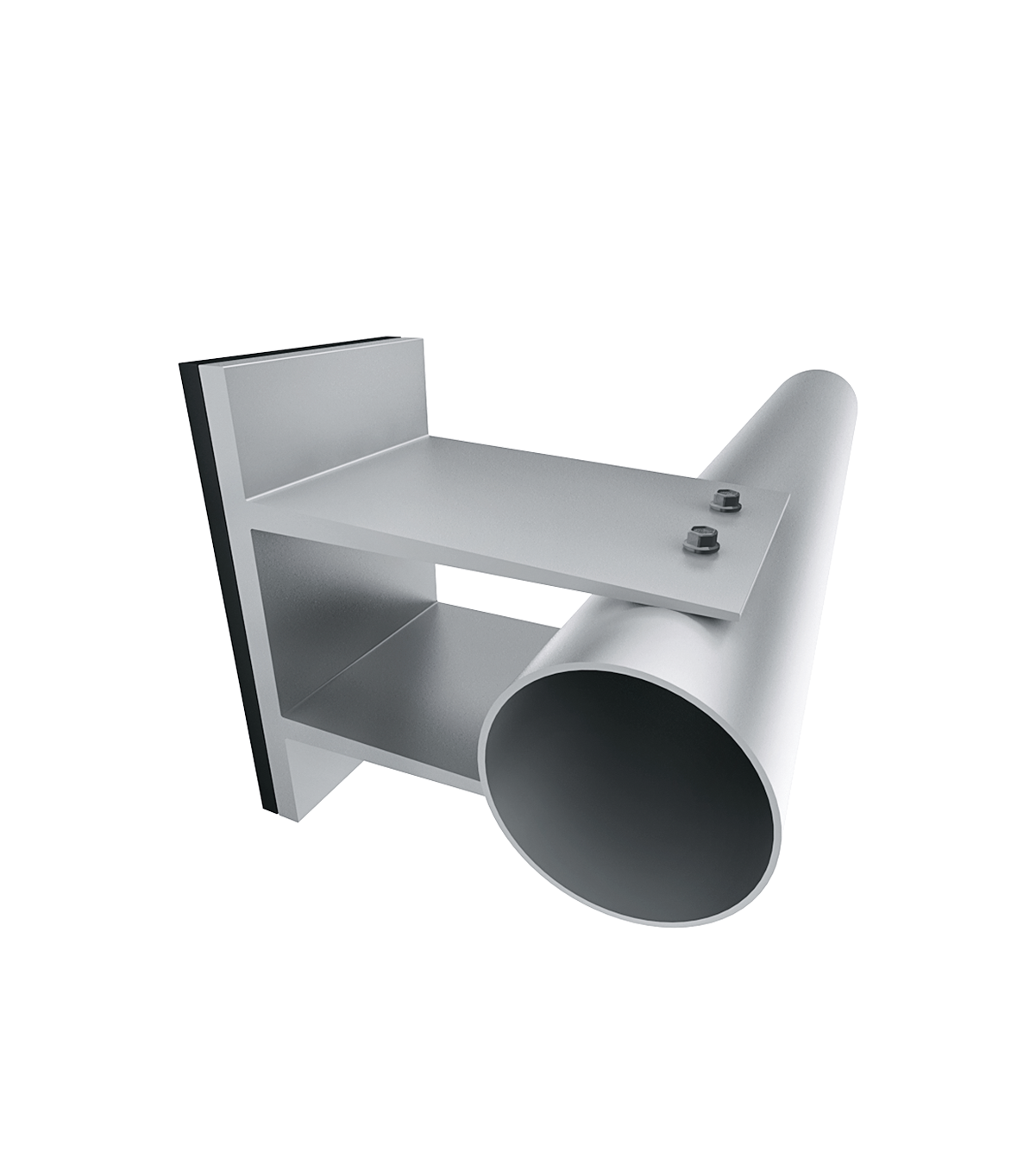

Standing seam roofs with support systems - no thermal bridges, optimal sliding properties, high load-bearing capacity

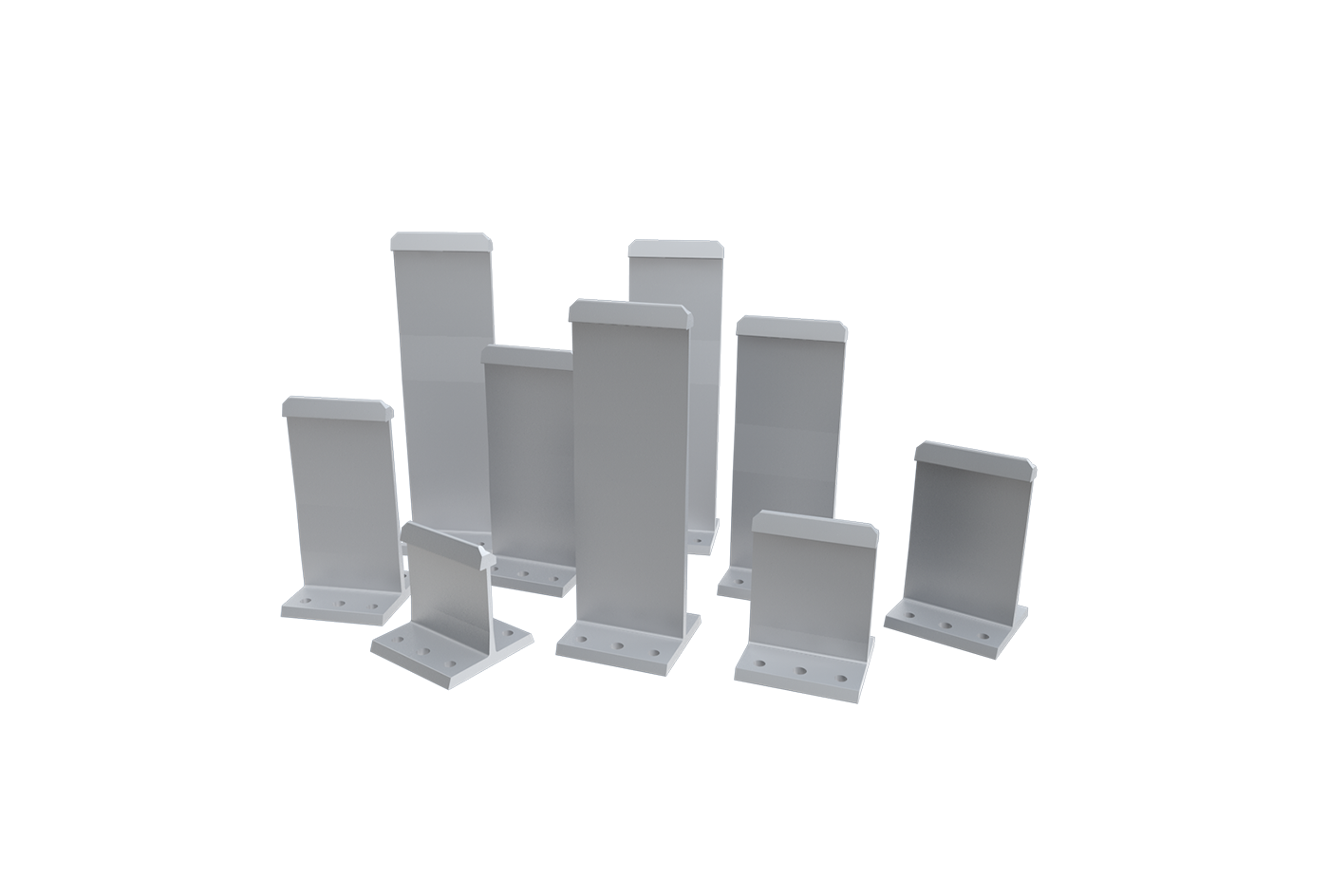

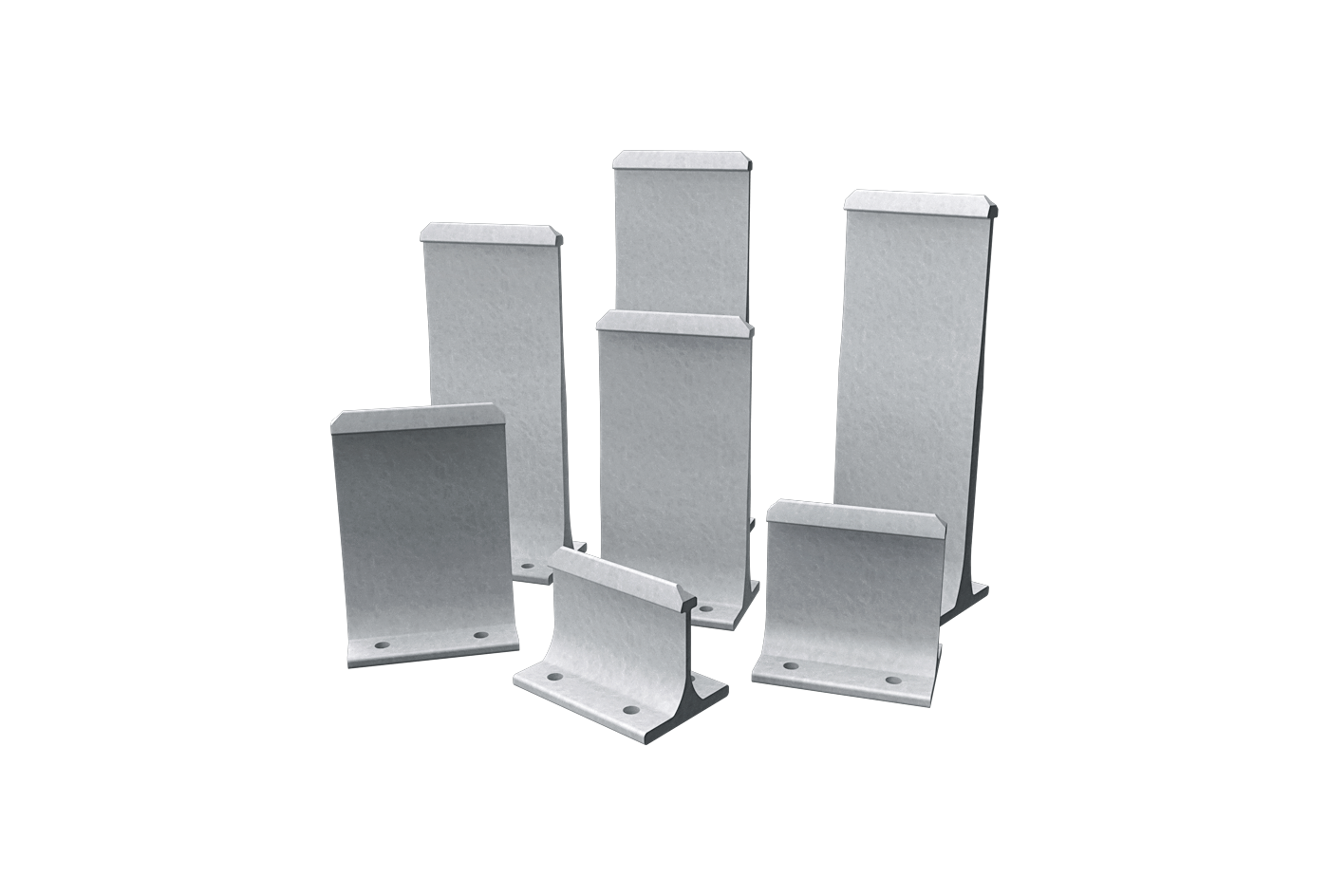

Aluminium or GFRP brackets for more load capacity of the roof

Roof bracket made of fibreglass-reinforced plastic for constructions free of thermal bridges (GFRP)

Building without thermal bridges to sustainably reduce energy costs

High-quality building shells with substructures from BEMO

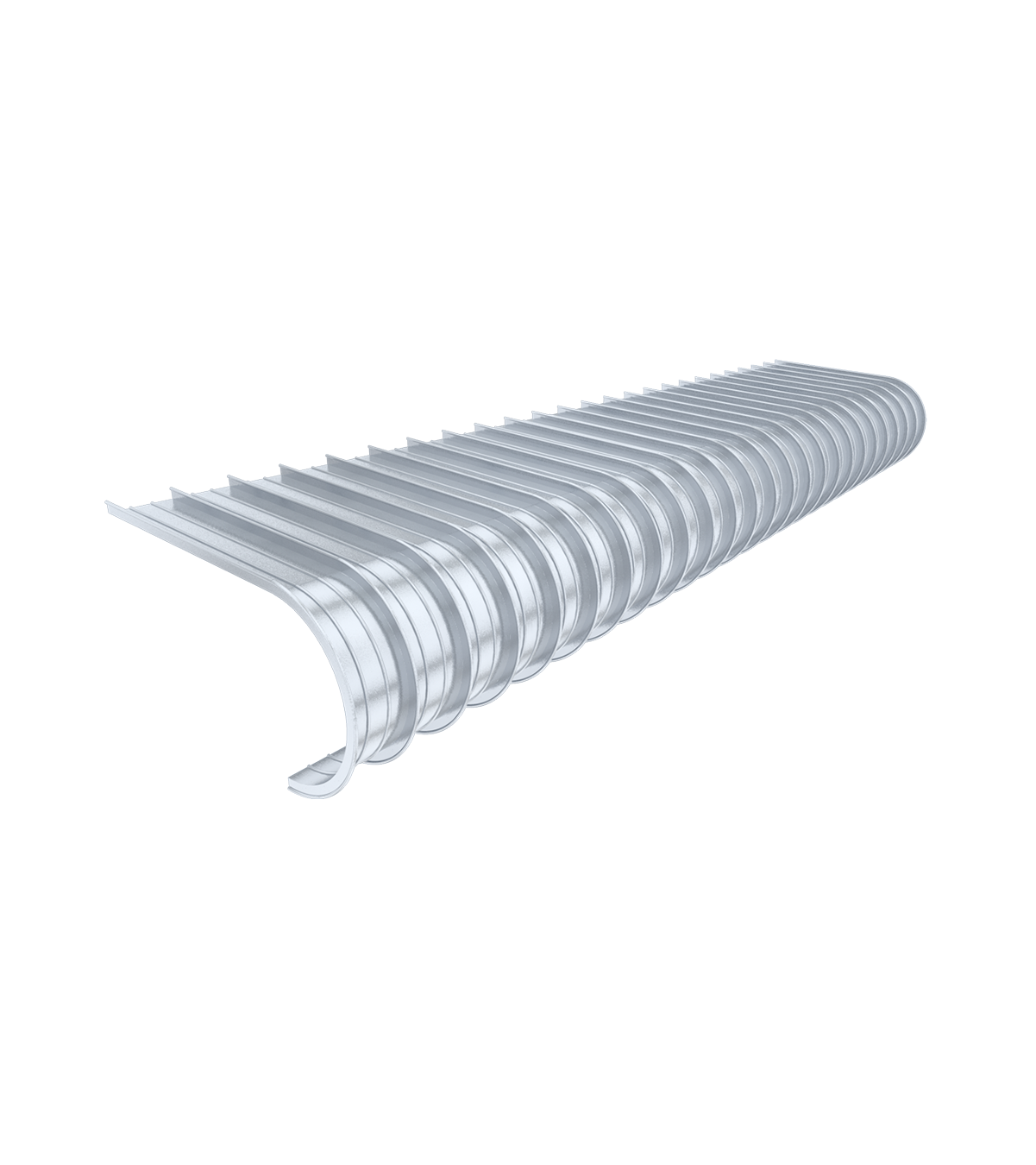

Custom-fit roofing with easy installation thanks to BEMO-FLEX

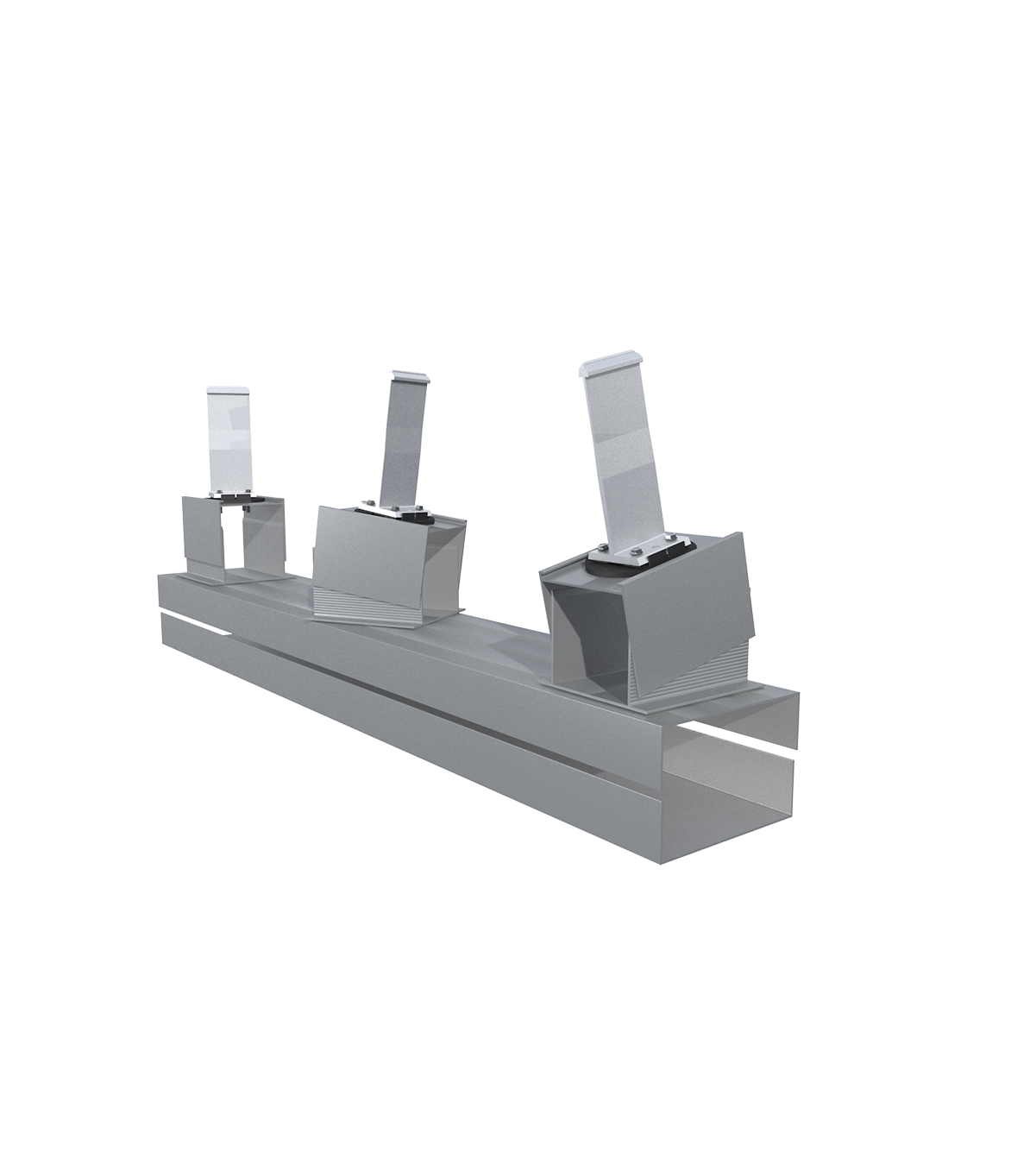

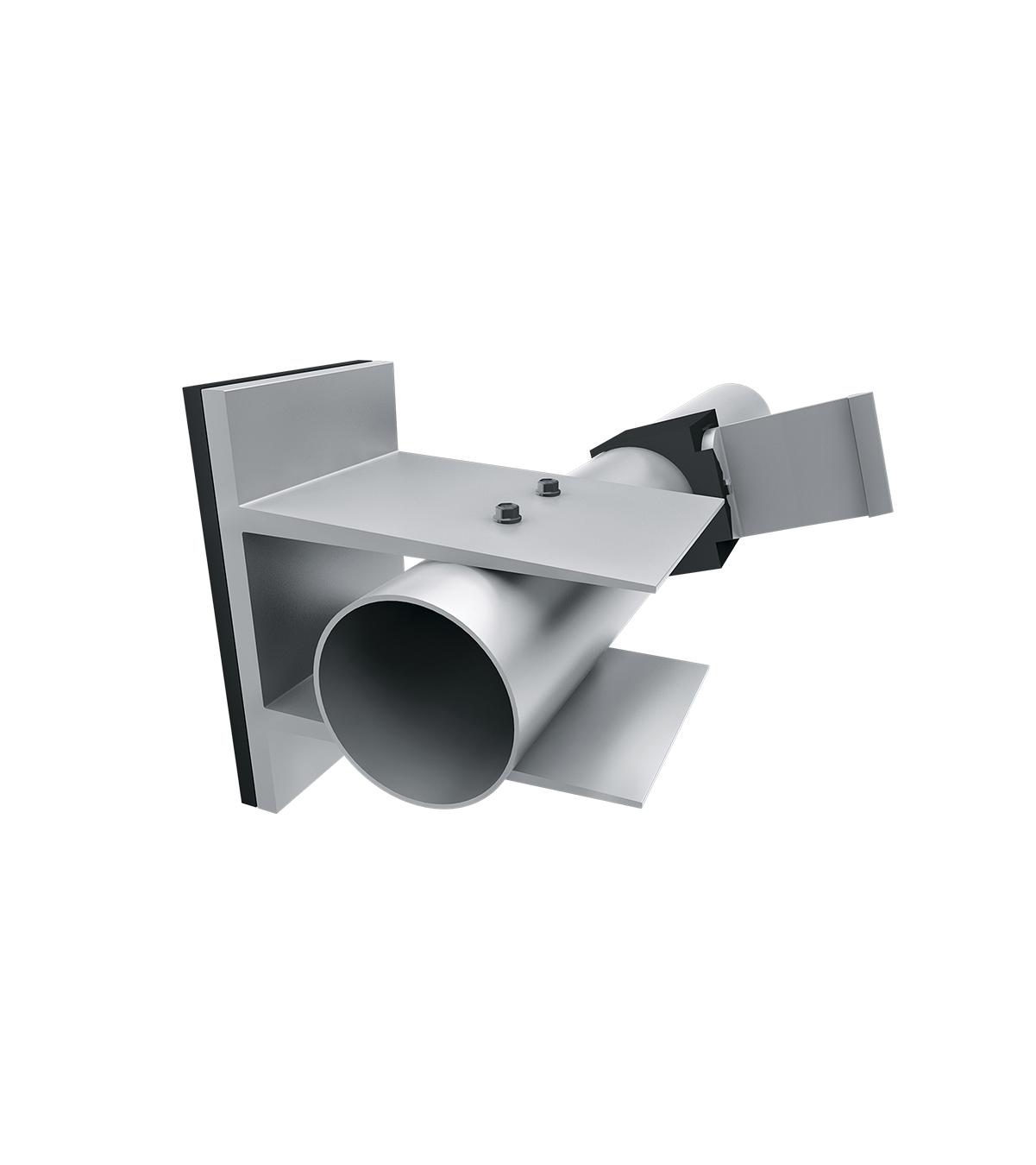

Modern computer design methodology combined with an inventory of current structures ensures that BEMO-FLEX can be used anywhere and that it is suitable for all our cladding profiles in roofs and façades. The installation of the lower U-profiles of the FLEX-SYSTEM is based on static specifications. For this purpose, the installation position of the U-profiles is recorded in a 3D scan. Thus, the necessary position and height of each BEMO roof holder can be derived. This is followed by the pre-assembly of the upper U-rail together with the positioning brackets in the workshop. In a final step, these are then screwed to the lower U-rail to complete the roof substructure.

With the appropriate design of the roof substructure, it is also possible to compensate very high tolerances or design new building shapes.

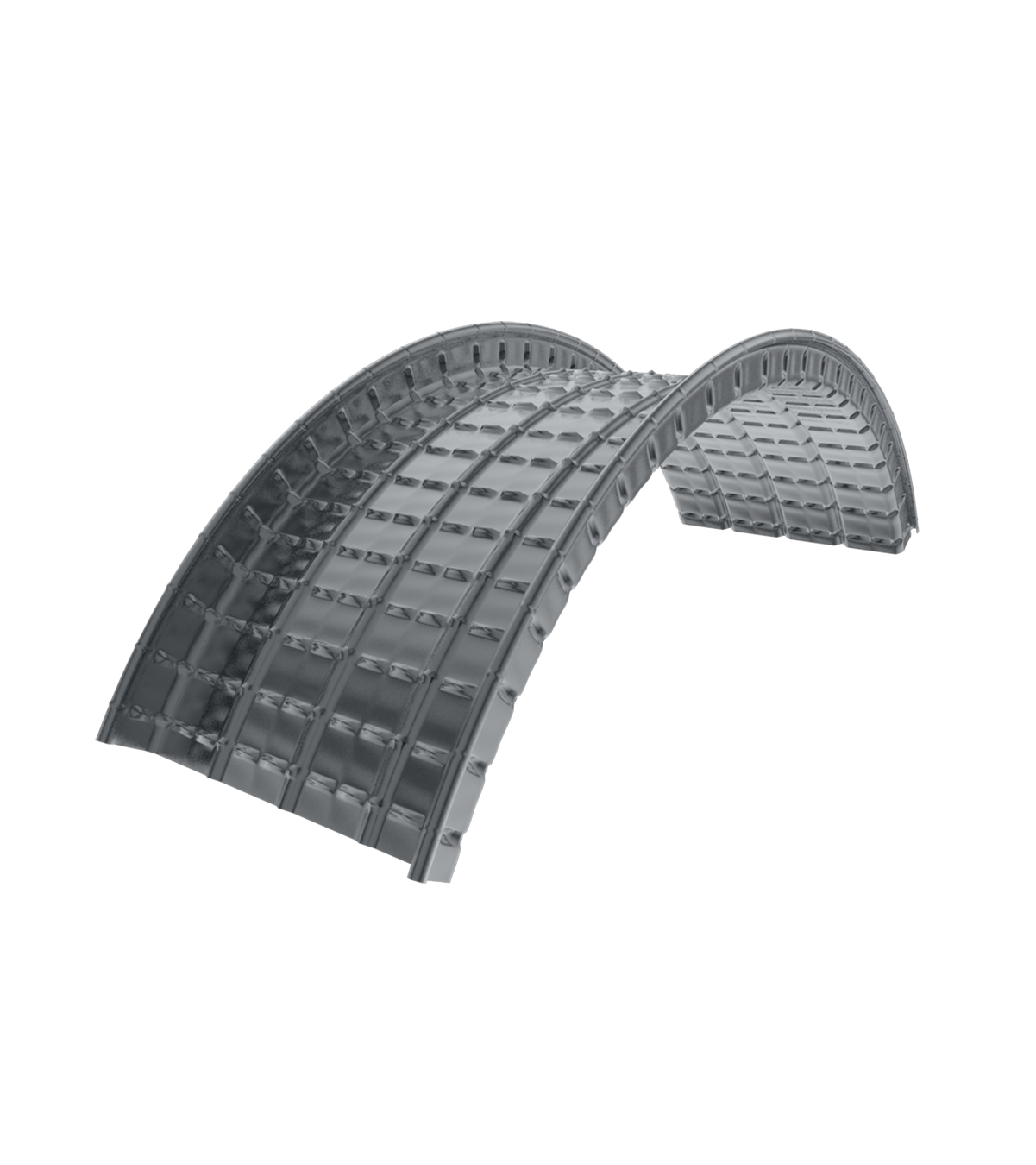

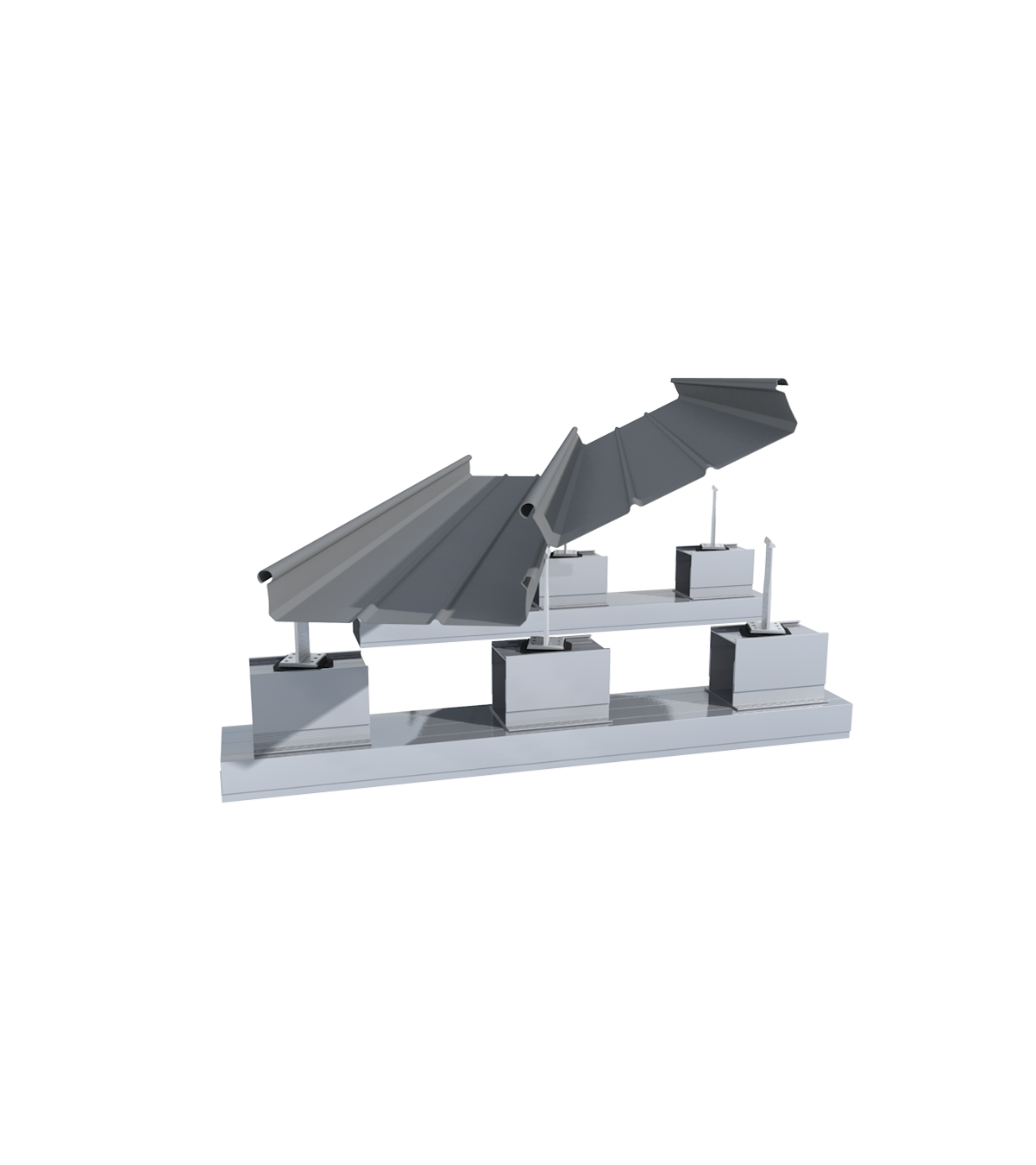

Curved building shapes with BEMO-DOME as substructure

The BEMO-DOME substructure is a suitable, highly flexible substructure solution, especially for cylindrical or biaxially curved building shapes and for standing seam systems. BEMO-DOME is mainly designed for facades of silo buildings, stadiums, oval towers (e.g. fermenters) or for transition areas from roofs to facades. The system meets all requirements, whether ventilated or non-ventilated construction of the metal roof structures.

For this substructure system, we recommend using a 3D scan as an on-site recording and BEMO execution planning in 3D in order to obtain a perfect surface of the metal profiles. As a result, you will receive a grid design with suggested attachment points and their distance and position to the supporting structure.

Inspiration

Casals Forum, Kronberg Academy

Trabzon Bus Terminal

Hotel L’EssenCiel

Novartis Pavillon

Garagum Hotel & Business Center

360° Service

Passion for innovation in roofs and facades. That is what sets us apart.

It is our passion to turn your individual idea into an innovative project. We work every day with joy and passion on the implementation. Our goal is clear: to create something unique and inspire with innovation. To ensure that this succeeds, our experienced project consultants work with you from the conception phase and support you with patented solutions from standing seam profiles to roofing membrane. No challenge is an obstacle for us. We always have a solution and, if necessary, even carry out measurements directly on site. Our global network is an enormous support for us. Reliable partnerships have been established and proven over the years. We can count on the good cooperation of our partners, especially in delivery logistics and material provision.

BEMO stands for synergetic partnership. This is our promise.