Aiming high with aluminium façades from BEMO

Highest safety and fire resistance for tall buildings

Highest fire resistance and safety complemented by maximum recyclability and separate recovery. Aluminium façades 3 or 4 mm thick are completely non-combustible and are A-classified. Whether designed as cassettes or as concealed fastenings with the INVISIO system. The passive house-certified substructure TEKOFIX A++ can also be used. Maximum thermal protection combined with the highest fire resistance: a façade system for the highest demands and skyscrapers.

-

Highest fire resistance

with A1 classification -

Passive house certified substructure

for maximum energy efficiency -

100 % recyclable

thanks to aluminium panels -

Large panel formats also possible

with the BEMO-INVISIO system

Aluminium façade panels in large sizes

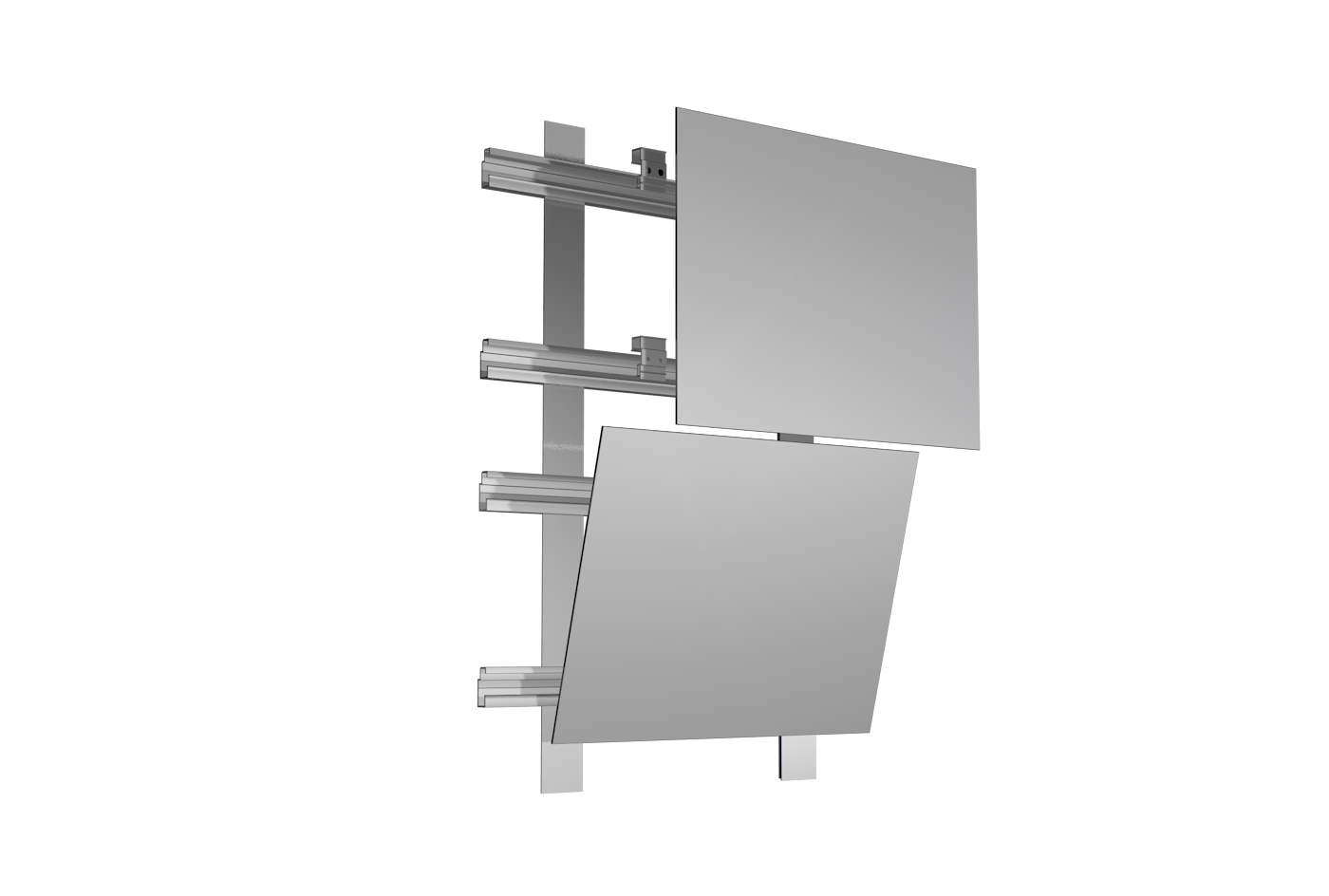

BEMO-INVISIO with all-aluminium panels makes innovations possible

The BEMO-INVISIO concealed fastening solution for large-format façade panels is also ideal for use in combination with A1-classified all aluminium façade panels. The panel undercut is CNC-controlled. BEMO’s patented system guarantees that no impressions from the undercuts are visible on the front of the panels. The anchoring in the aluminium panel is extremely sturdy and permits large panel formats without additional bracing, even within areas of the building subjected to high winds.

The surfaces of the façade are coated, powder-coated or anodised. Adjustable and year-round installation completes the ingenious system and sets new possibilities in the high-rise sector as well.

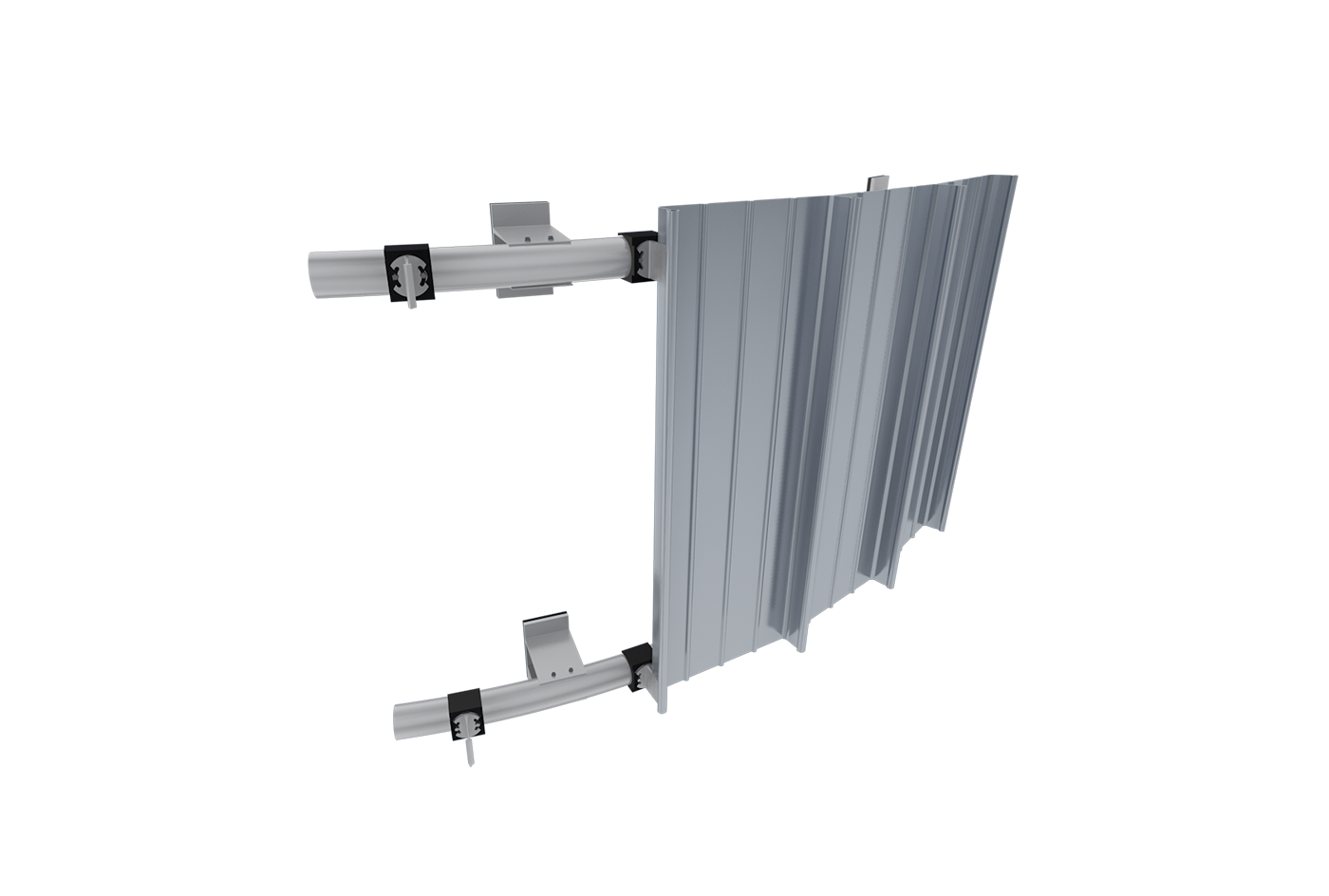

Substructure systems for façades with aluminum composite panels

The link without thermal bridges

The substructure forms the connection between the load-bearing wall and the façade cladding. It is attached to the outer wall and transfers the weight of the façade cladding to the structure of the building. Tolerances are compensated with the innovative substructure systems from BEMO for rainscreen façades or aluminium façades. It is also ensured that the façade is installed without thermal bridges. We will work with you individually to determine which design fits which requirements. We work closely with you, taking all the circumstances into account, and design the ideal aluminium façade cladding with the right façade system with you.

360° Service

From measurements to complex 3D planning

In BEMO’s own planning office, an expert team of technicians and engineers works on the implementation of your project – equipped with the latest 3D planning technology, some of which has been developed in-house. This team accompanies you in all project phases: After the initial consultation, it goes into the implementation of the desired design, the choice of materials and the design. We carry out the first technical details and static preliminary measurements and take over the complete implementation and workshop planning.

Cost estimates, technical improvements or variant calculations help you to improve your project economically. 3D measurements are the basis for our assembly-friendly, well-thought-out systems and for implementation in 3D planning. This is what a synergetic partnership with BEMO looks like.