Aluminium composite panels in any design

Wide range of design possibilities with BEMO-BOND

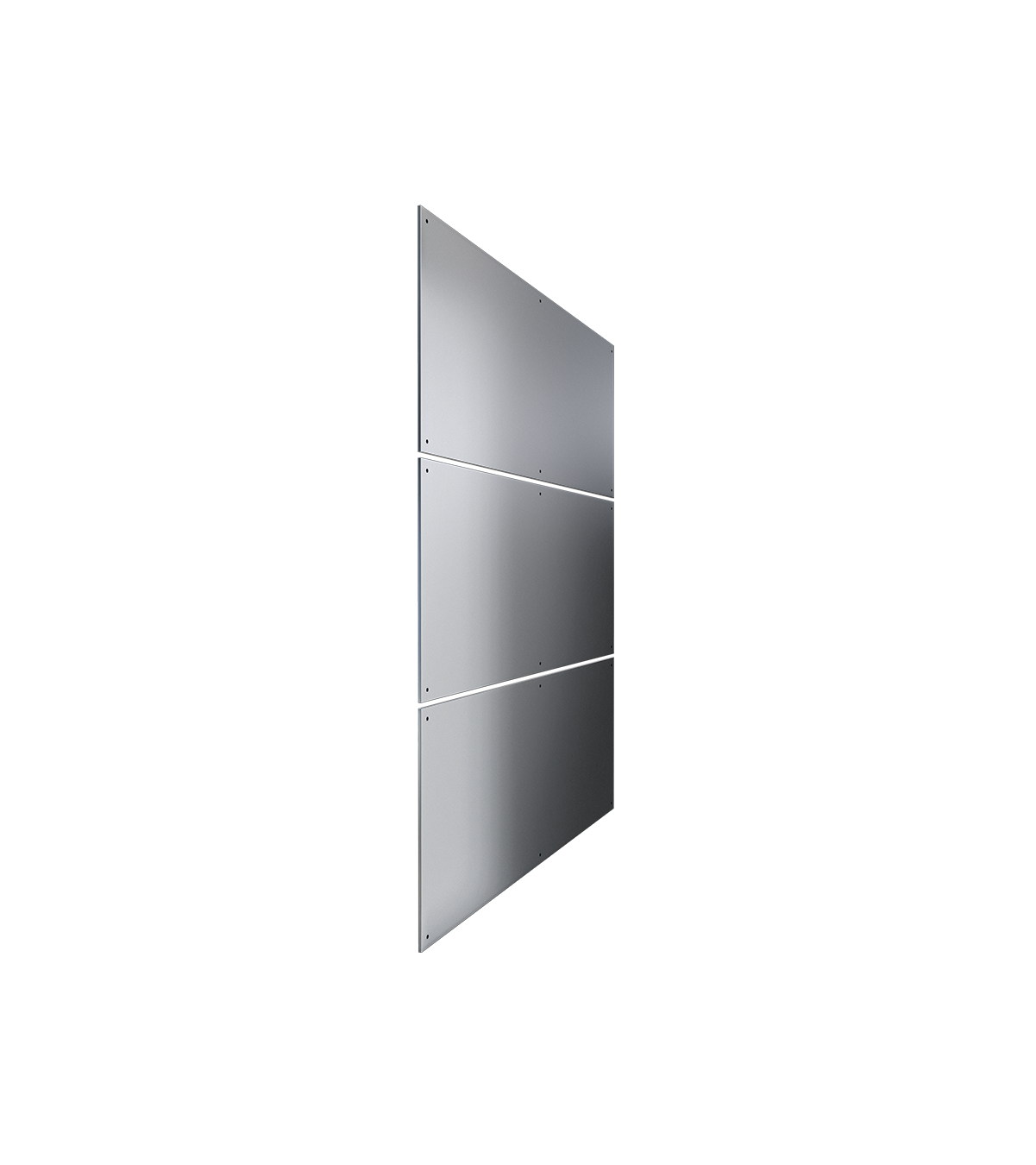

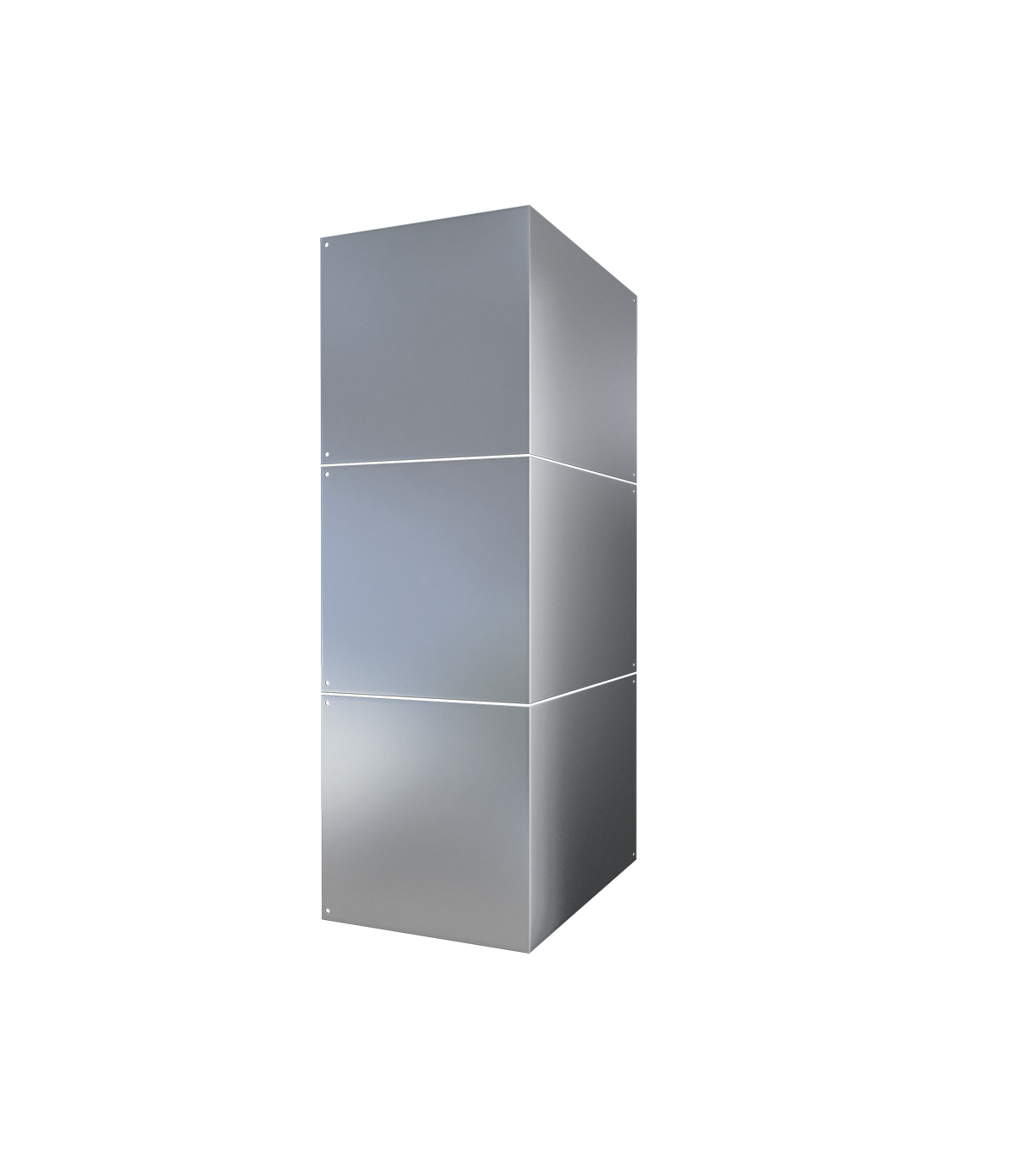

As a high-quality façade cladding for rear-ventilated curtain walls, BEMO-BOND aluminium composite panels can be used in a wide variety of designs. Visibly or invisibly fastened – in freely designable, different panel dimensions of 6,000 mm x 2,000 mm – with a wide variety of colours and individually designed detail solutions.

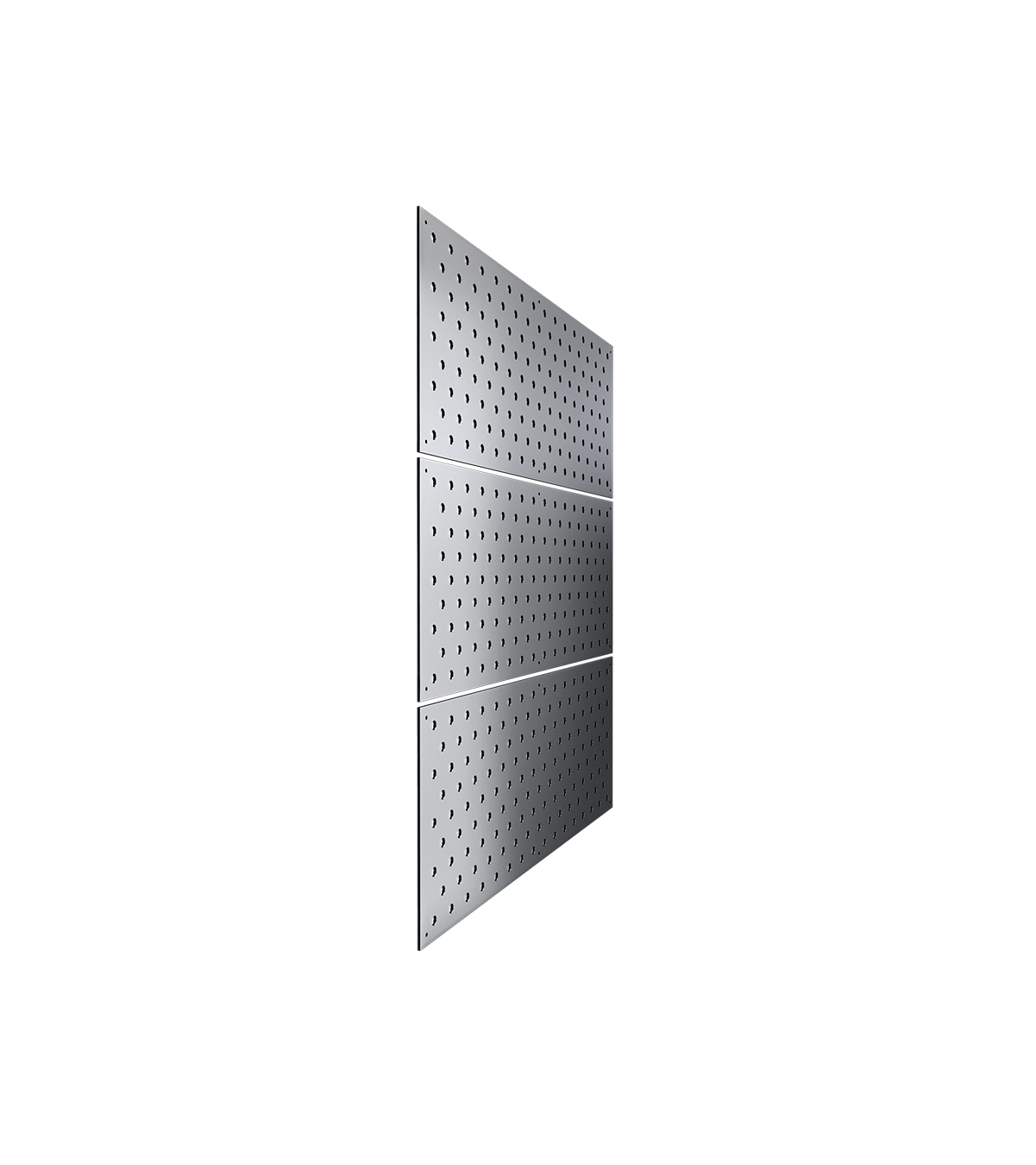

Perforated backlit elements on request, the possibility to integrate lettering, coats of arms or logos – the design possibilities with BEMO-BOND aluminium composite panels are almost limitless. Also available as non-combustible composite panel in building material classification A2.

-

Freely designable, different panel dimensions

of 6,000 mm x 2,000 mm possible -

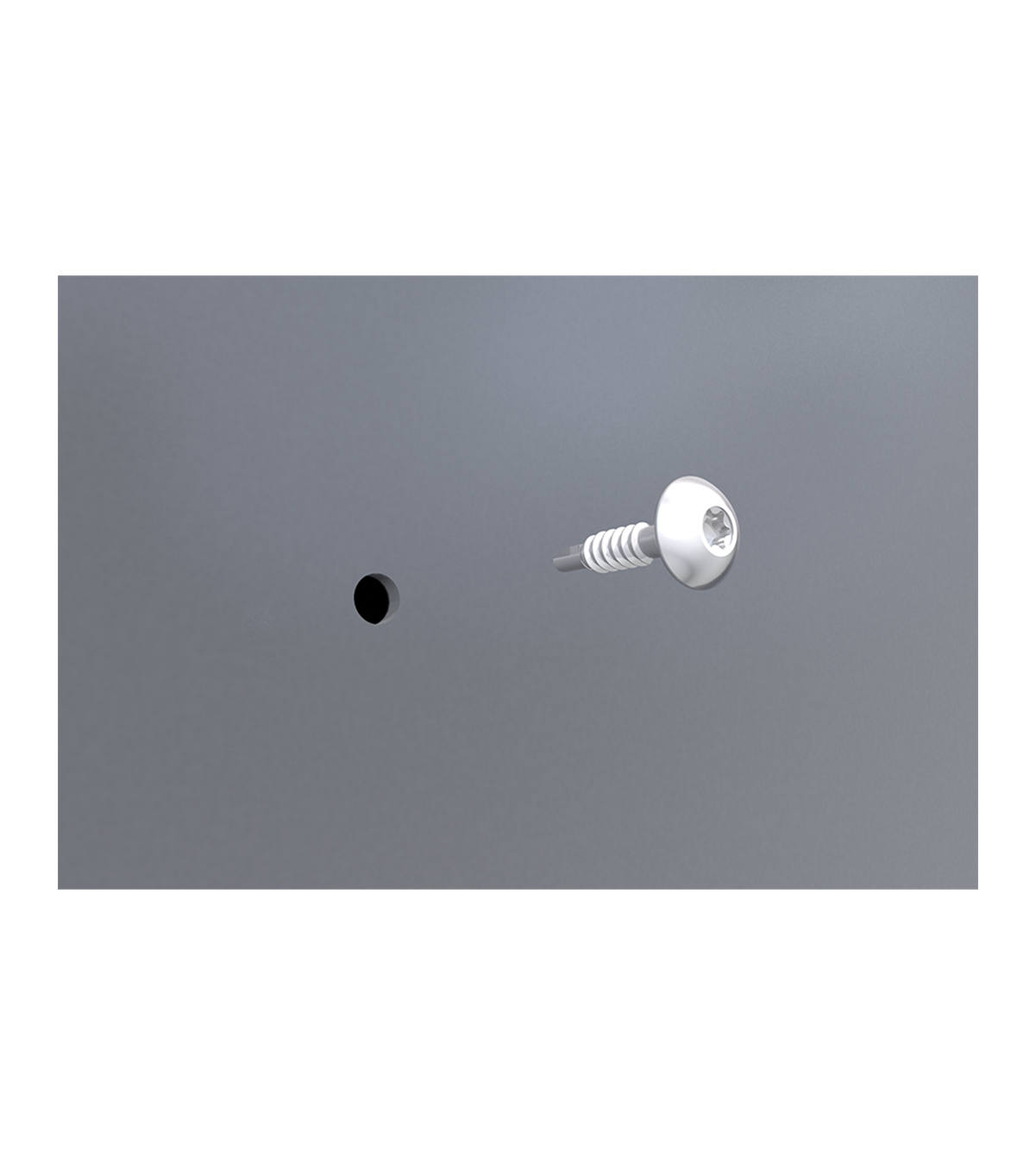

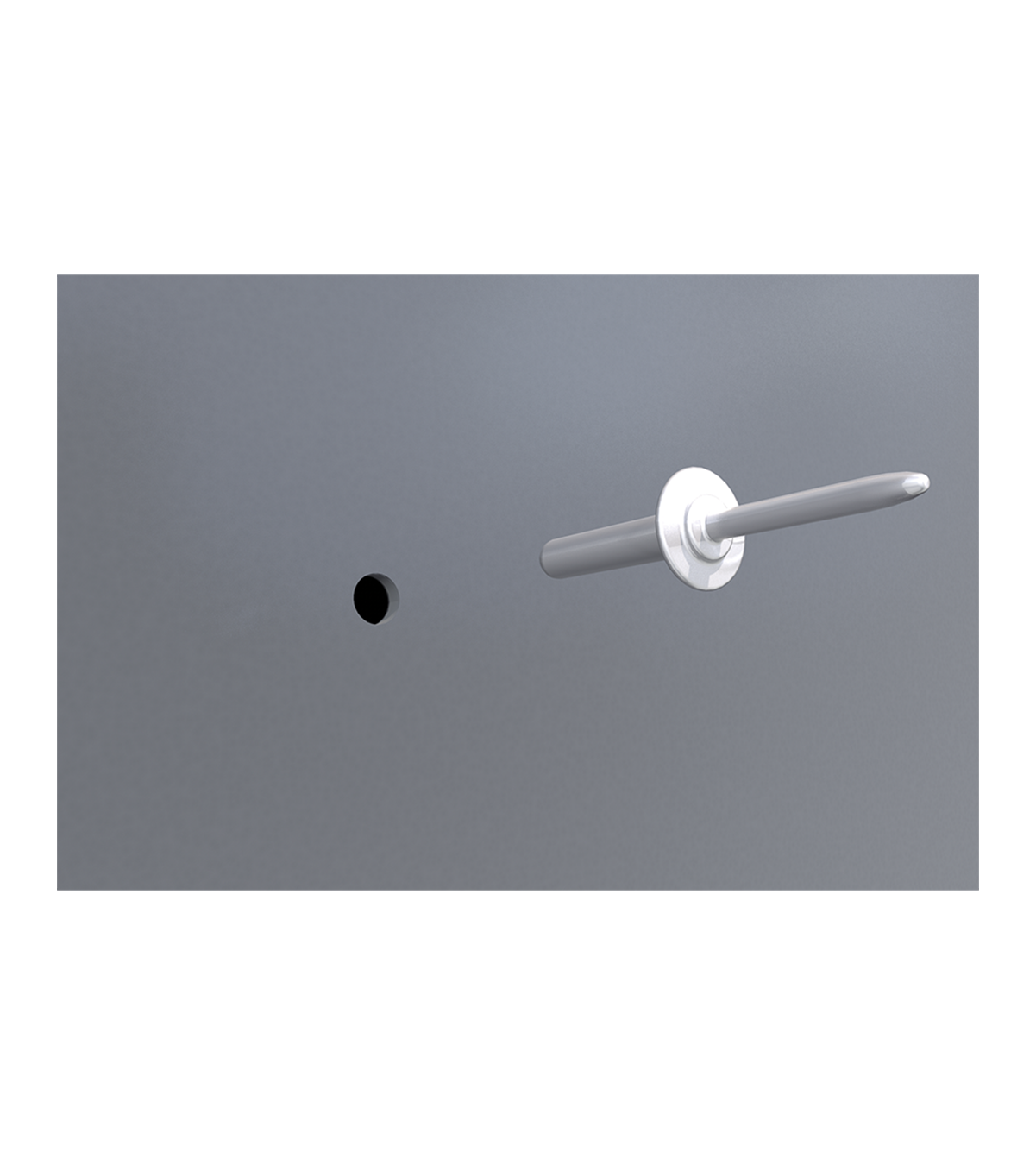

Visible and non-visible fastening

by means of screws or rivets -

Closed cut edges possible

and in surface colour feasible -

Fire classifications include B-S1, dO and A2-S1, dO

or as non-combustible composite panel in aluminium A2 -

Countless design possibilities

also with perforated and backlit elements -

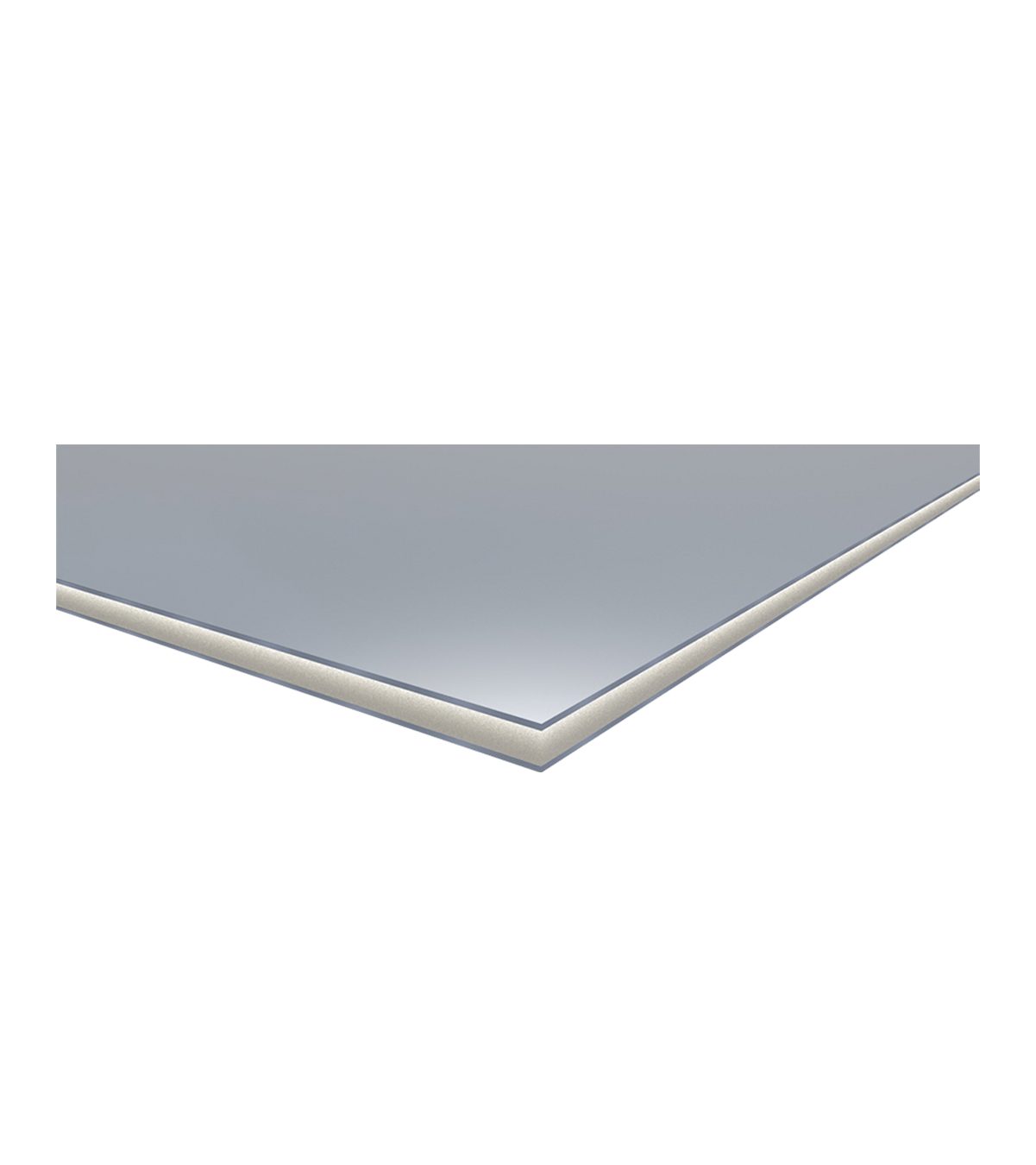

4mm or 6mm

Panel thickness

Aluminium composite panels individually manufactured at our own production facilities

BEMO-BOND aluminium composite panels come in the complete BEMO colour palette. You can also mix your own colour preferences in the BEMO colour laboratory. Matching connecting and edging parts can be ordered and supplied from the same batch. Panel fastening can be done visibly, e.g. by means of screws or rivets, in panel colours. Concealed or invisible fastenings can be designed as a cassette system or with the innovative BEMO-BOND INVISIO system. Optional sealed edges close the panel core and give the panel the same surface colour all round.

Processing of the aluminium composite panels is done in our own processing centre, on the basis of the BEMO execution design. The panels are pre-processed according to requirements and delivered to the project just-in-time. The fire classifications are B-s1,d0 and A2-s1,d0. The panel thickness can be 4 mm or 6 mm.

Closed Edge

Perforated

Corner Lipping

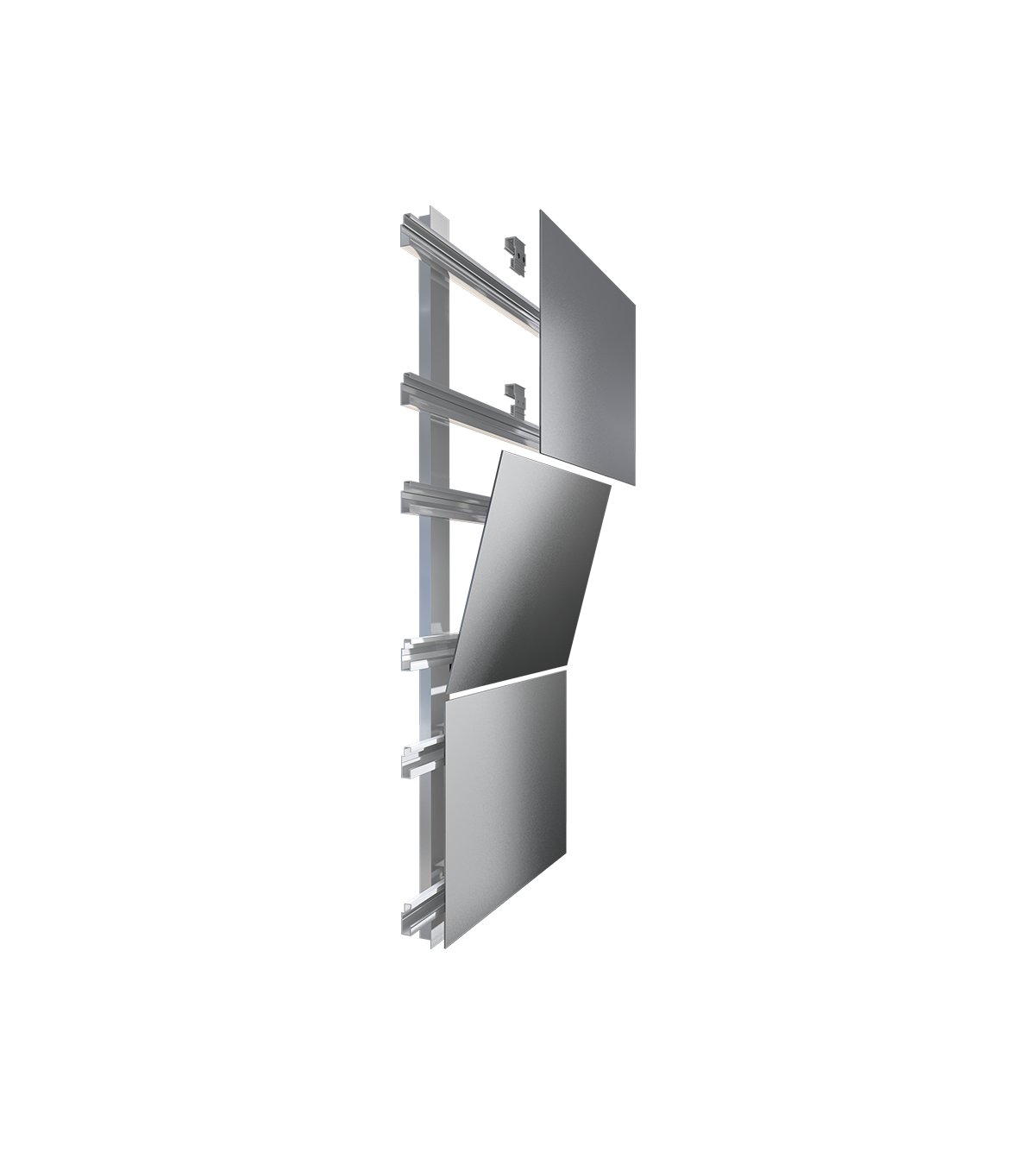

BEMO-BOND INVISIO

Rounded Panels

Screwed plate

Plate riveted

Open edges

Closed edges

BEMO-BOND INVISIO aluminium composite panels for façades

High-quality appearance thanks to concealed mounting

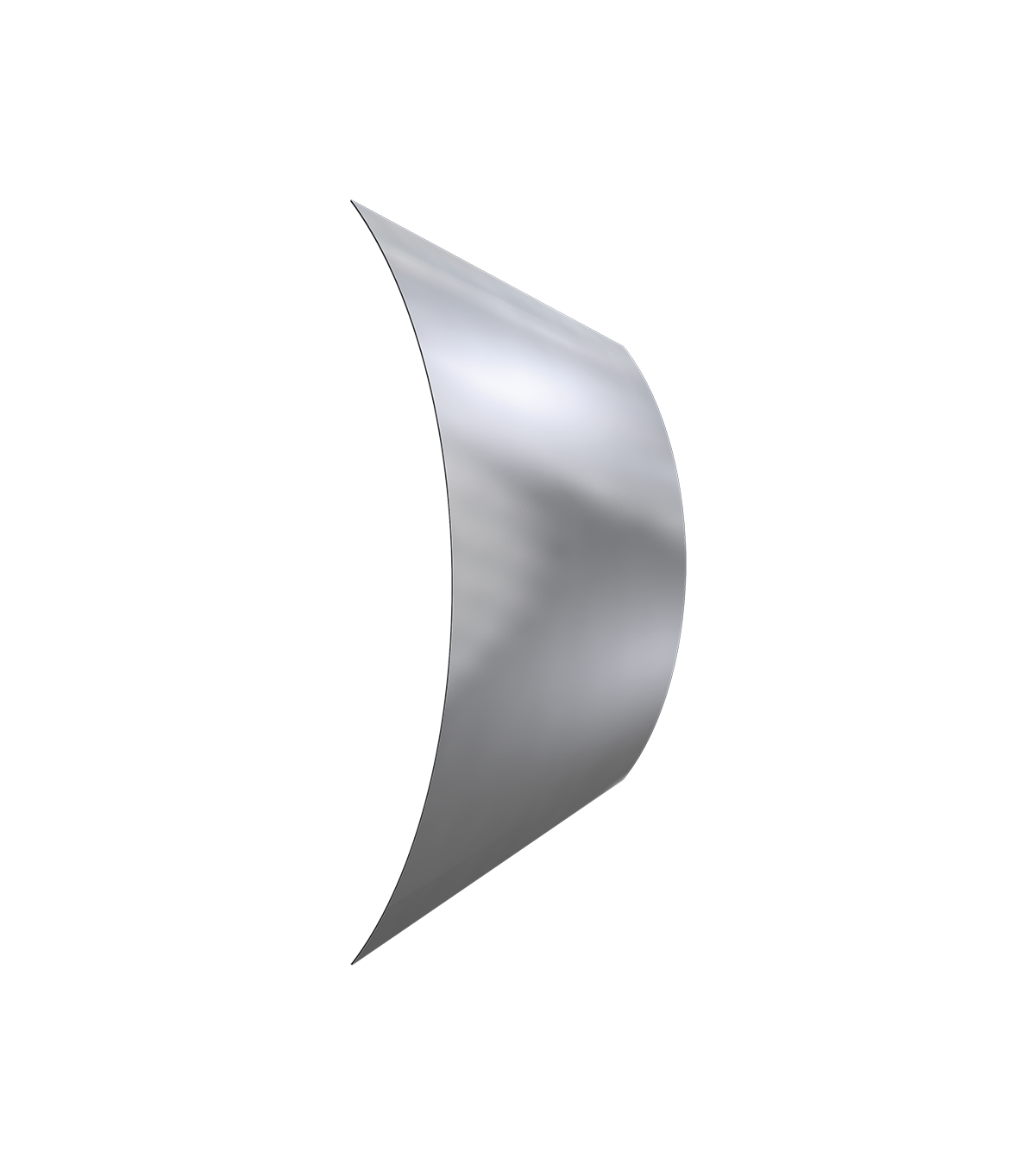

The system gives architects and designers the possibility to use very large panel sizes (up to 6,000 mm x 2,000 mm) and make the joints almost invisible. The linear expansion of the composite panels for the façade takes place via the sliding suspension on the substructure rails. Grout can be used with the panels in the same colour tone that surrounds them and is permanent and secure. High-quality perforated finishes and closed cut edges as well as perfect corner and reveal formations complement the high-quality appearance of the BEMO-BOND INVISIO façade. Of course, BEMO-BOND INVISIO can also be curved in large radii.

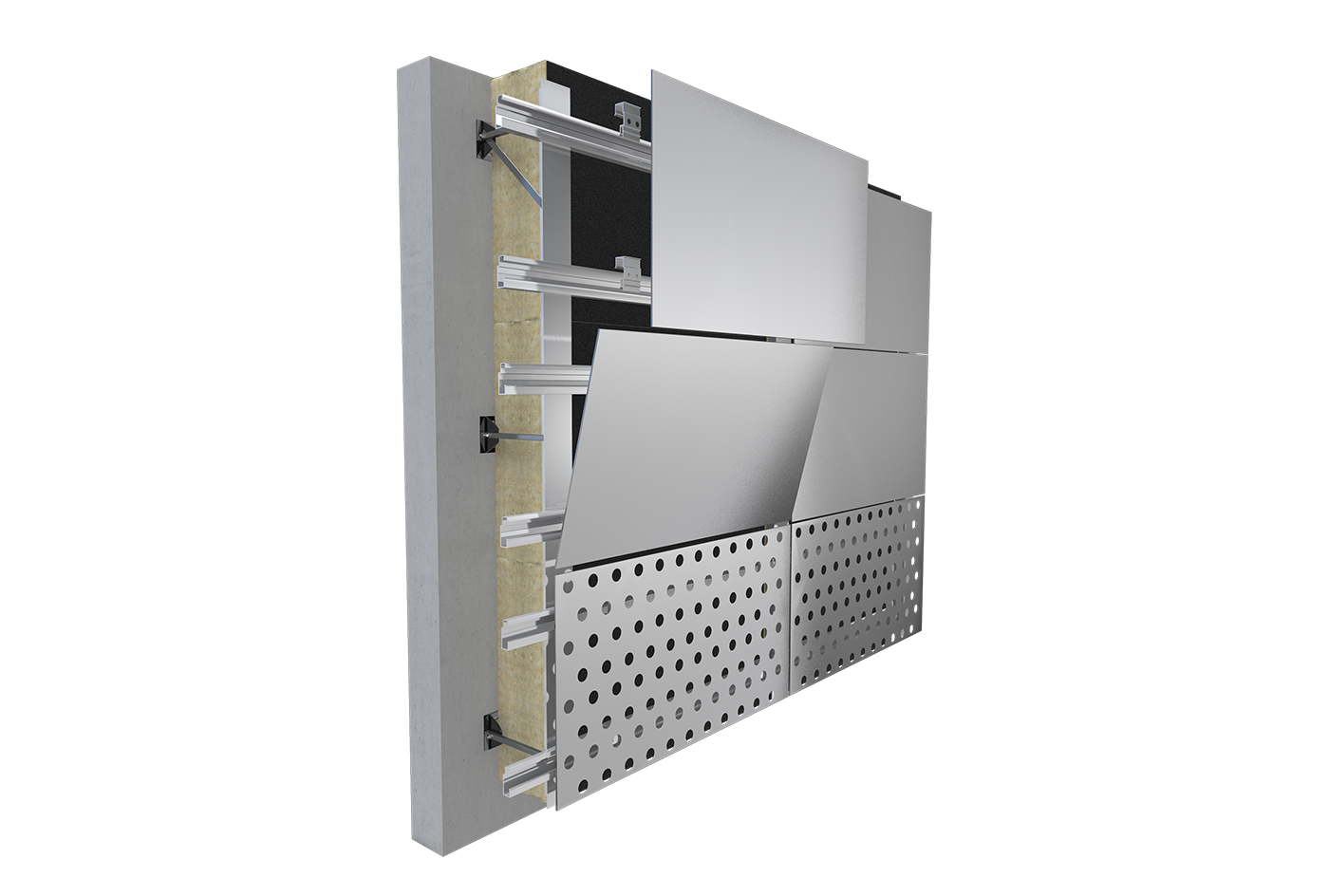

Substructure systems and façade systems with composite panels

Compensate for tolerances – avoid thermal bridges

The substructure is the link between the load-bearing wall and the façade cladding. It is anchored in the exterior wall and therefore transfers the weight of the façade cladding to the structure of the building. BEMO offers innovative substructure systems for rainscreen façades and aluminium composite panels that compensate for tolerances and are free of thermal bridges. We are happy to work with you to determine which substructure fits your requirements, taking all circumstances into account.

Inspiration

Car wash Mr. Wash

Manching airfield maintenance hangar

Koblenz Chamber of Handicrafts (HwK) Canteen

Mo.Ki Centre

Rheinfelden Industrial School

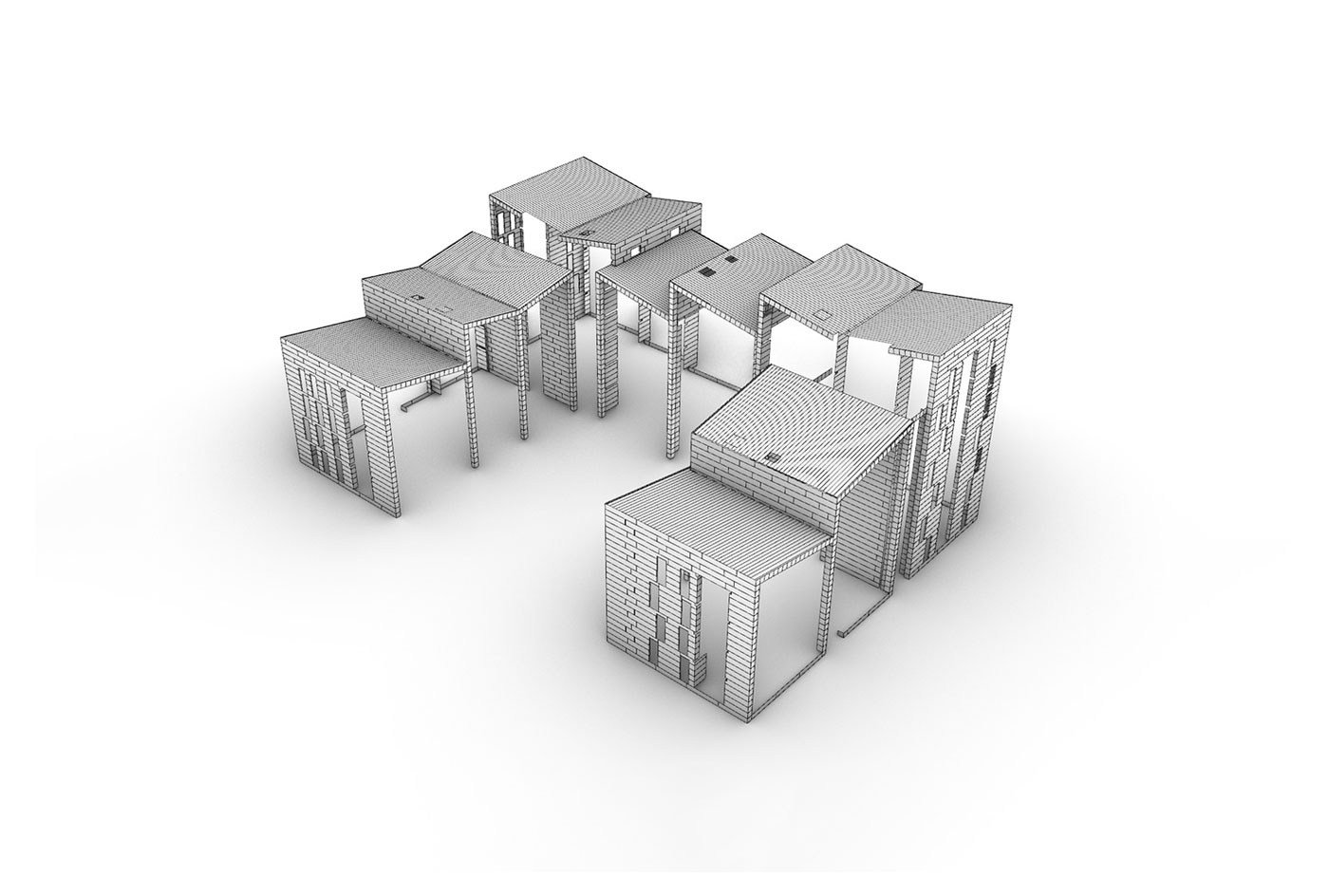

360° Service

Best technical support

In BEMO’s own planning office, you can expect system-experienced technicians and engineers – equipped with innovative and, in some cases, specially developed planning technology with 3D. From the initial consultation to the implementation of your design ideas, the design and choice of materials, the first technical details and static preliminary measurements through to holistic implementation and workshop planning.

This also includes cost estimates, technical optimizations and variant calculations that help you to optimize your project economically. The optimal basis is the 3D measurements for our proven and easy-to-assemble systems and the implementation in 3D planning. For us, all of this is part of a comprehensive partnership with BEMO.