BEMO profile façades with corrugated & trapezoidal profiles

The classics: cost-effective and reliable

BEMO profile façades are an interesting design alternative that give a special look to particularly large surfaces. Corrugated profiles and trapezoidal profiles are particularly economical façade solutions and are mainly used in commercial and industrial buildings.

BEMO corrugated and trapezoidal profiles not only offer a high degree of individualisation possibilities due to different profile geometries. In combination with a wide range of options for colours, surfaces, and materials, they give every building a lively appearance.

-

Lively appearance

due to different profile geometries -

Laying of the profiles

horizontal, vertical or diagonal -

Substructure without thermal bridges

for optimum energy efficiency -

Particularly economical façade solution

especially for commercial and industrial buildings

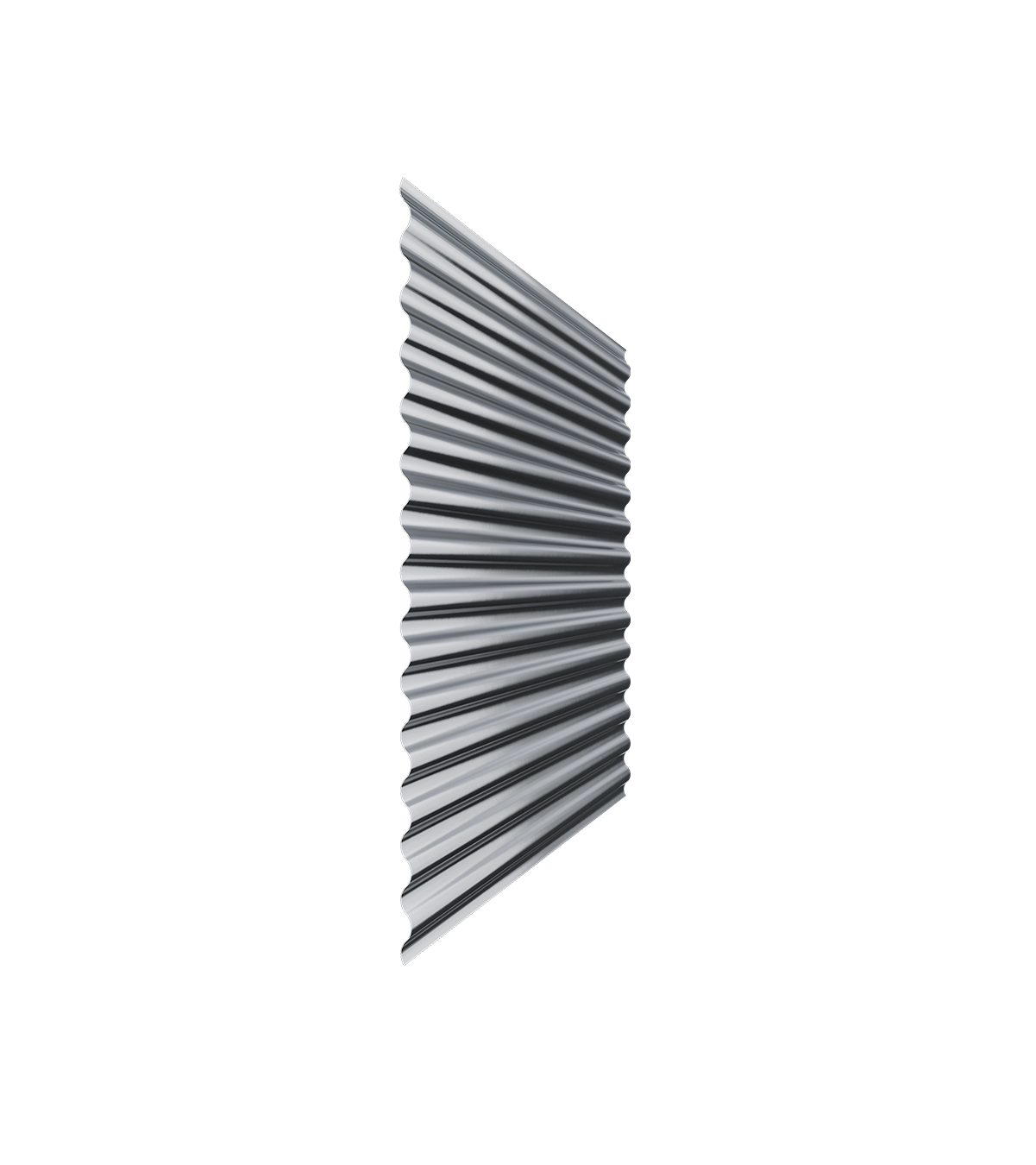

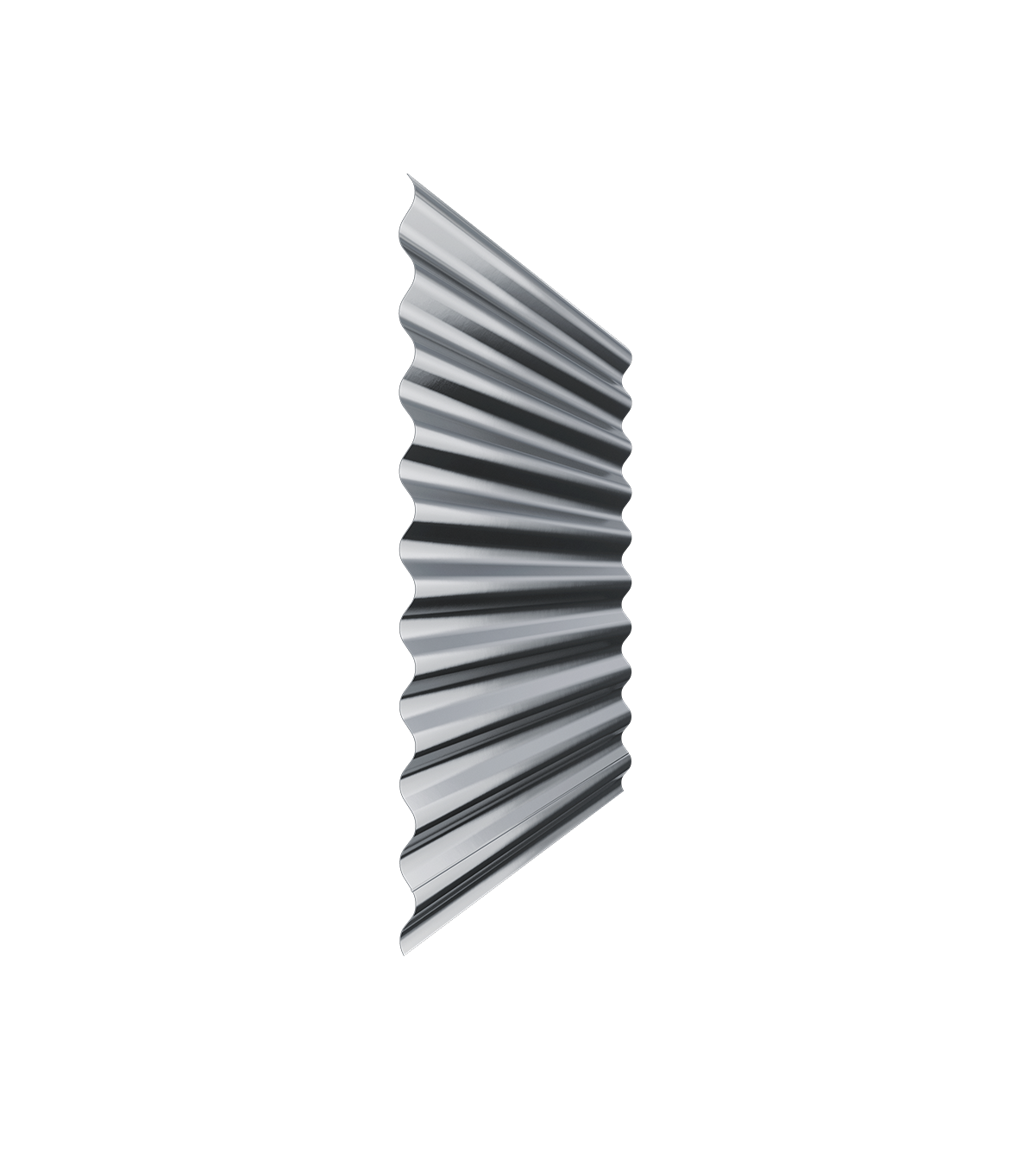

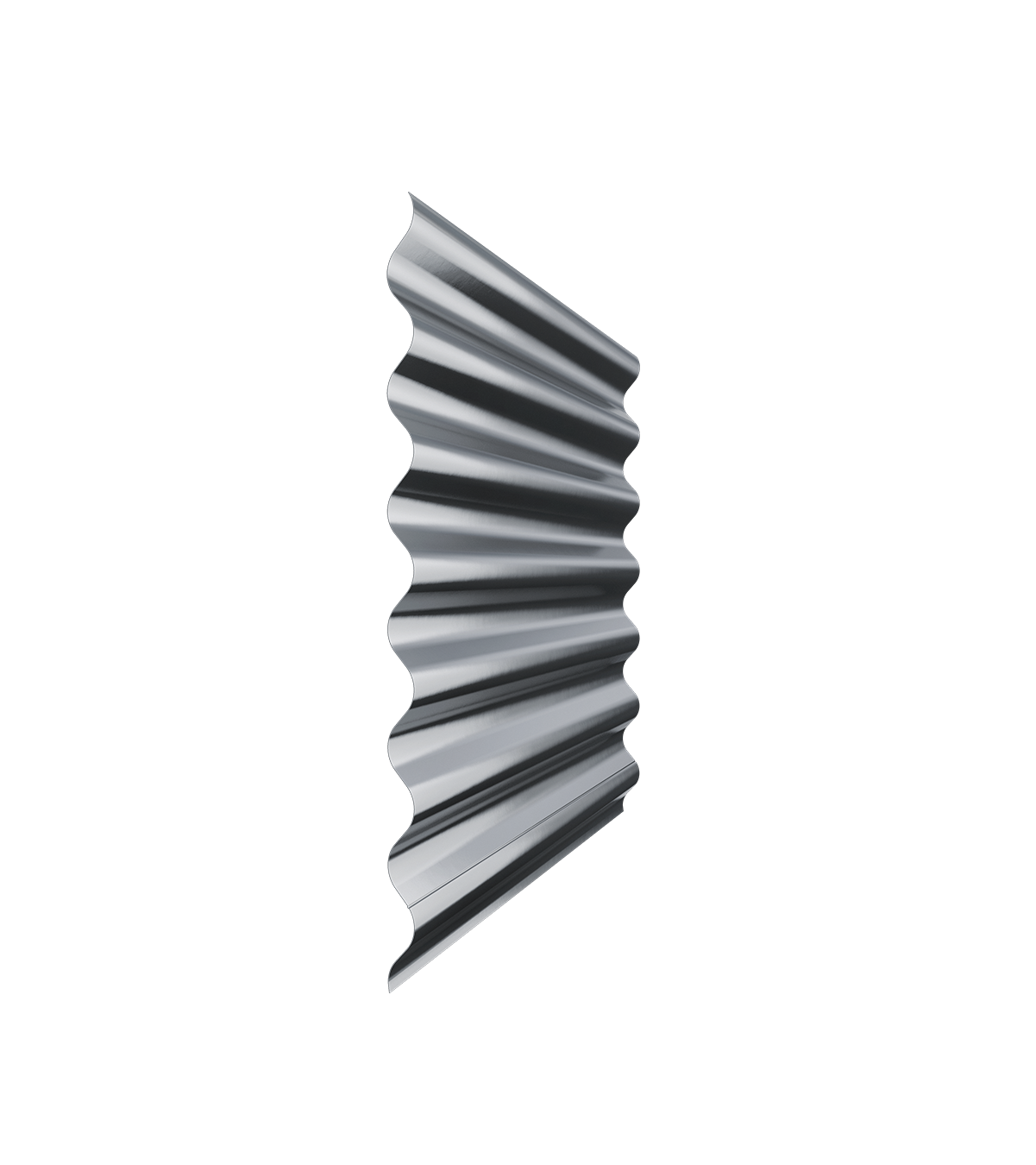

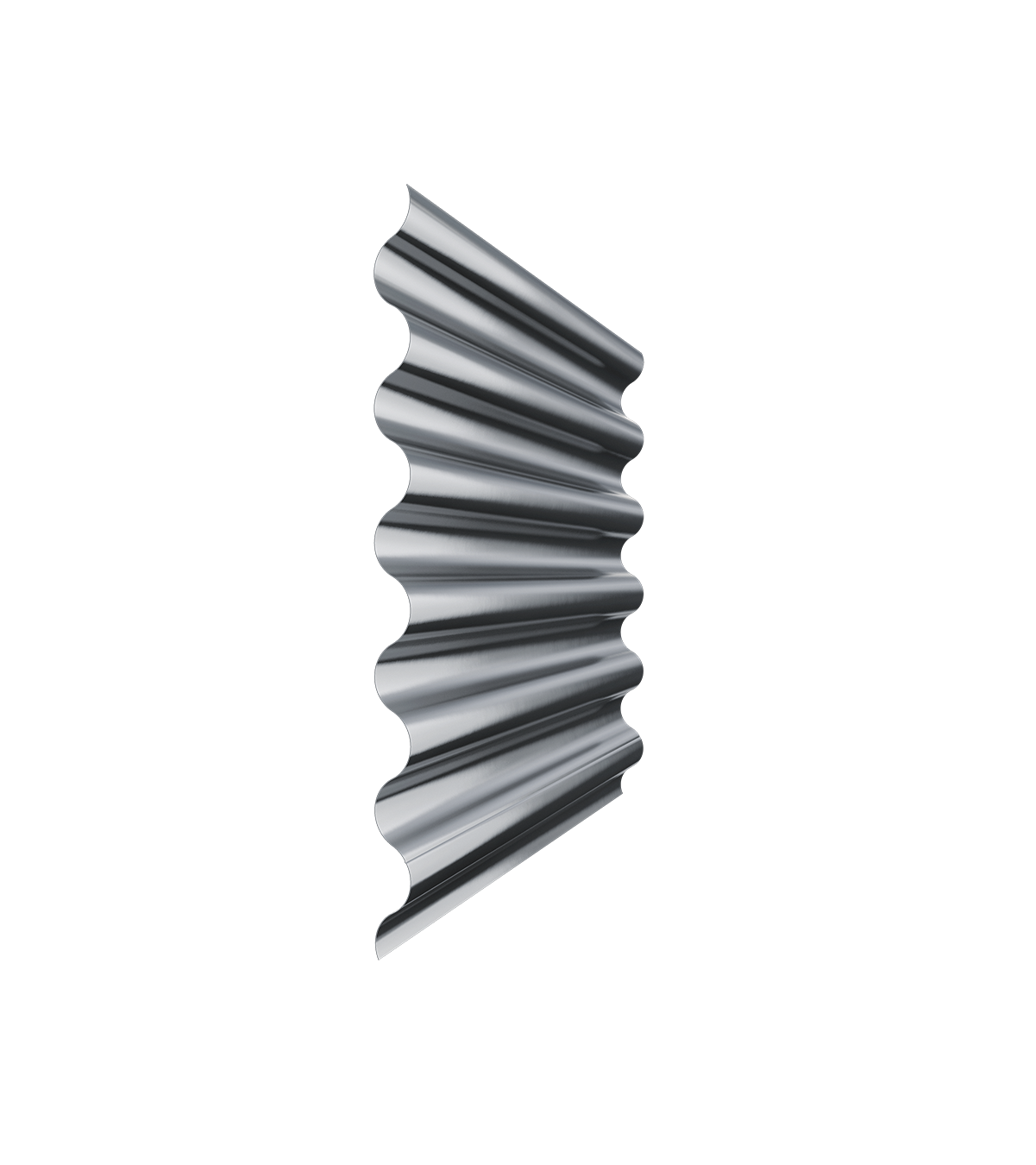

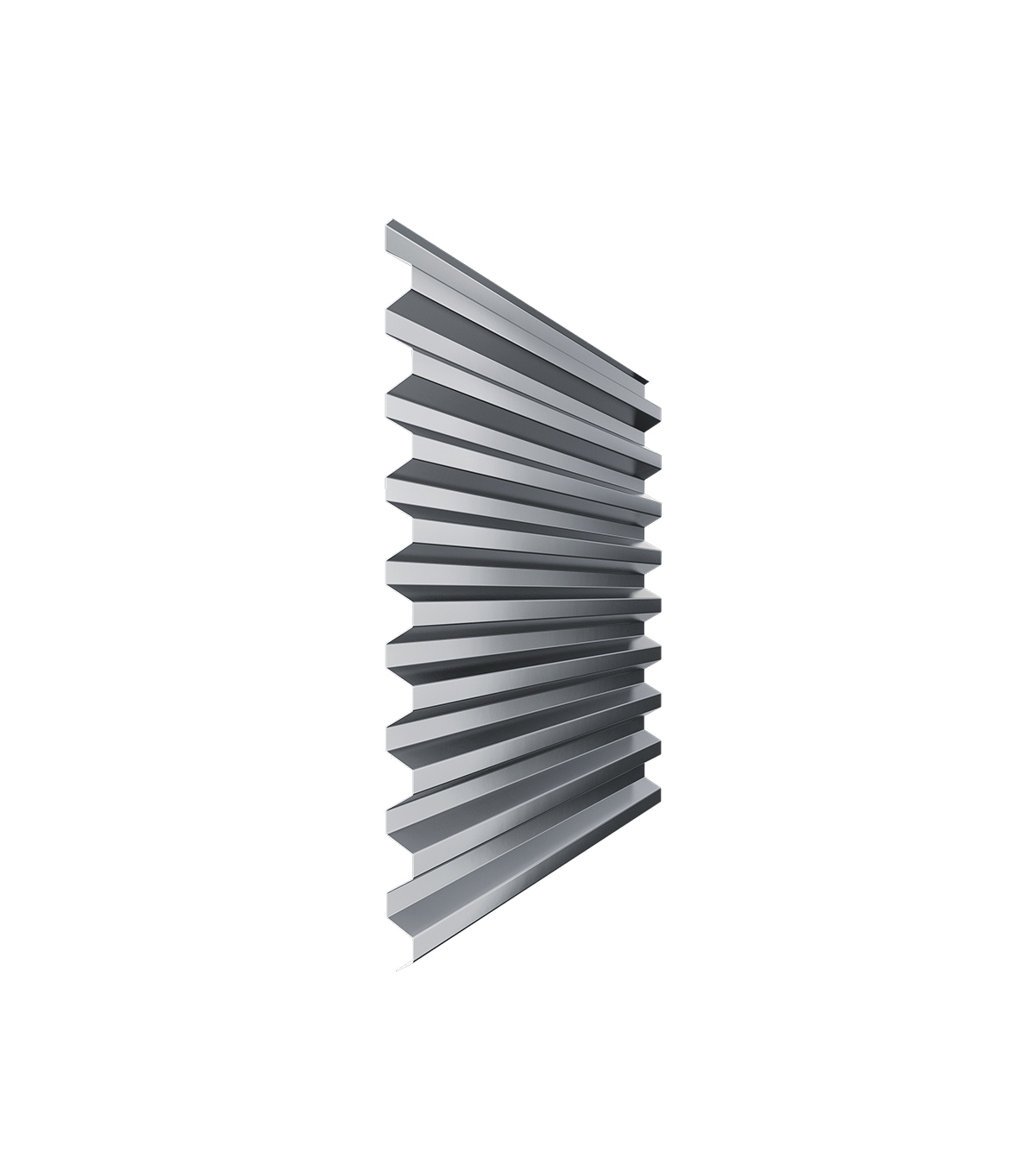

Corrugated profiles from BEMO in many variations

Countless possibilities in façade design with corrugated profiles

Depending on the size of the façade area, you can choose between four different sine waves. Each profile can be used both horizontally and vertically. Rainscreens are preferably installed using thermal bridge-free BEMO thermal brackets. An extensive range of system accessories rounds off our range of corrugated profiles.

WP 18-76

WP 27-111

WP 42-160

WP 55-177

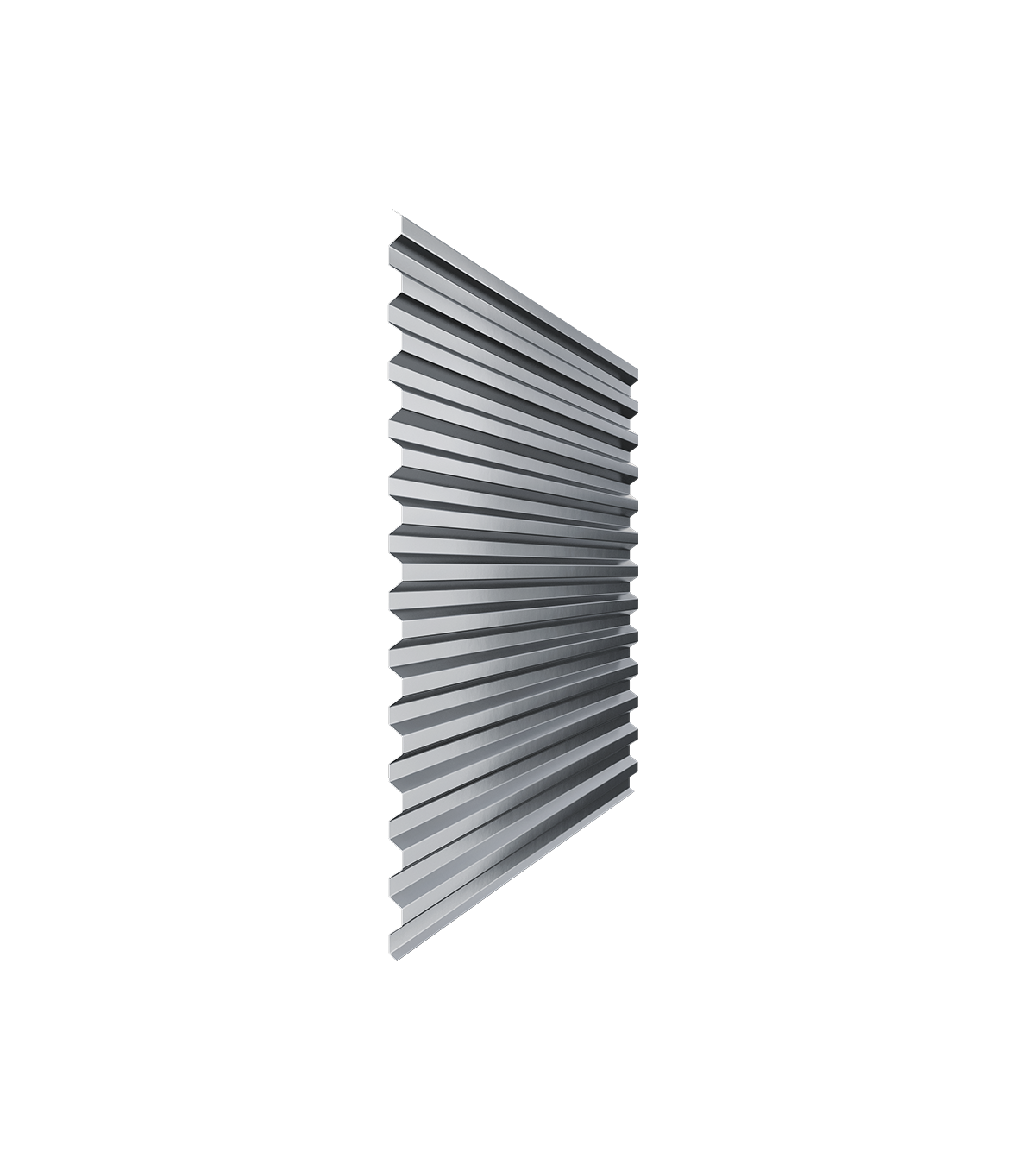

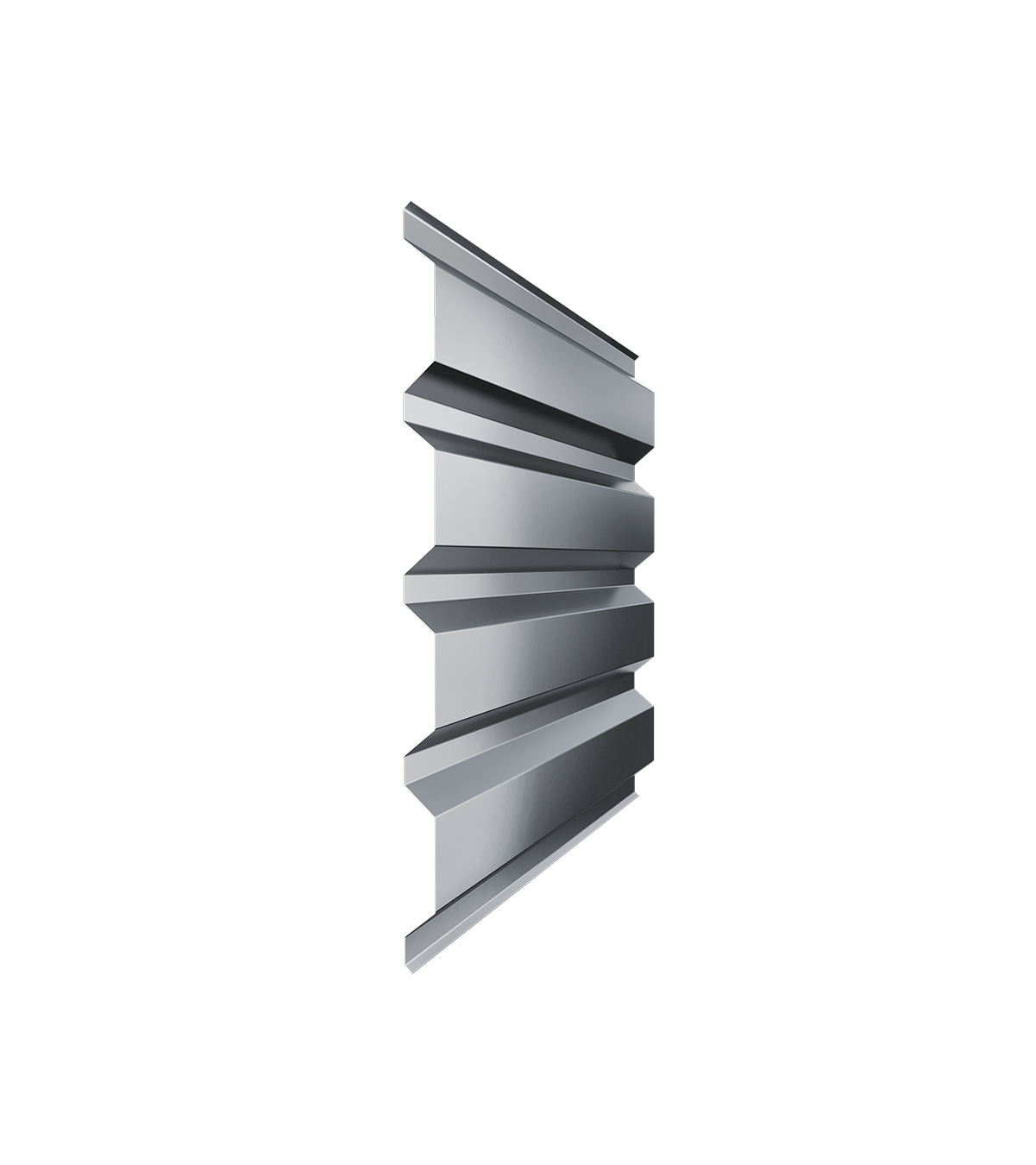

BEMO trapezoidal profiles with design variation

Design and functional diversity for façades

TP 20-75

TP 37-207

TP 40-100

TP 50-250

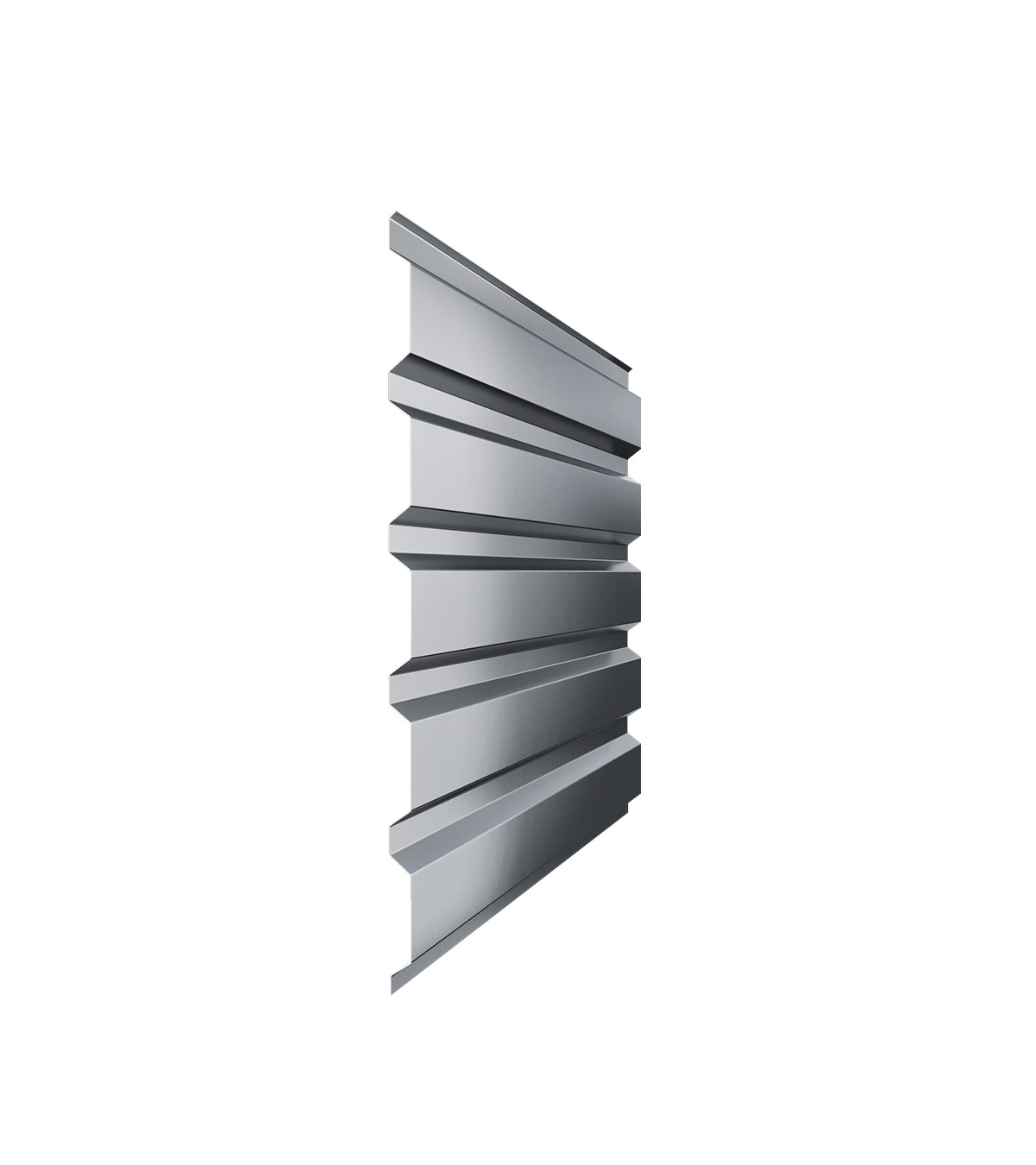

BEMO-UNIKO façade profiles

High-quality façade design with individual designs

BEMO-UNIKO panels all have one thing in common: they are made of metal. Starting from this basis, there is almost unlimited freedom of design in terms of materials, colours and grid widths. As a shady, functional building envelope, BEMO-UNIKO profiles made of metal can also be supplied in a perforated version.

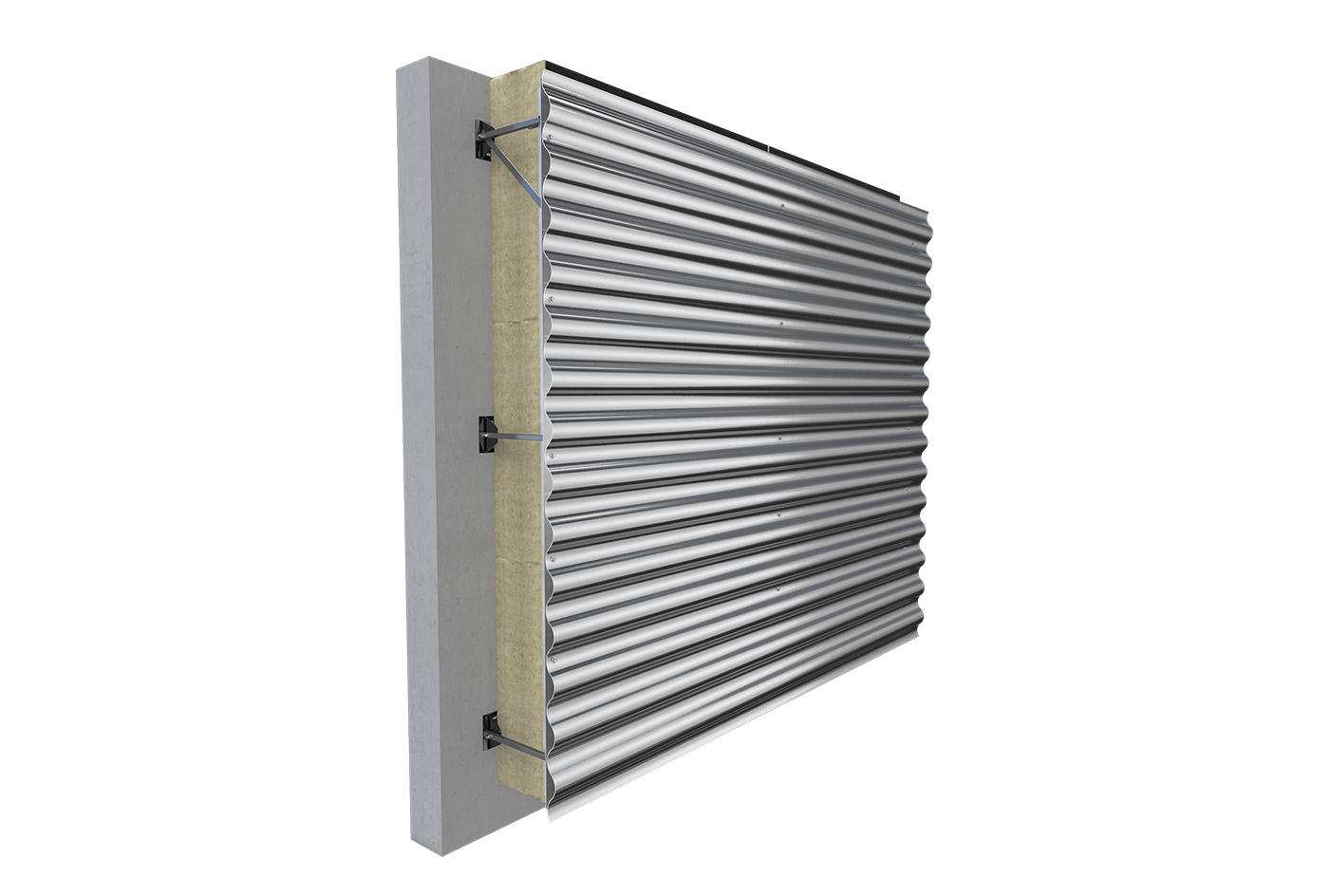

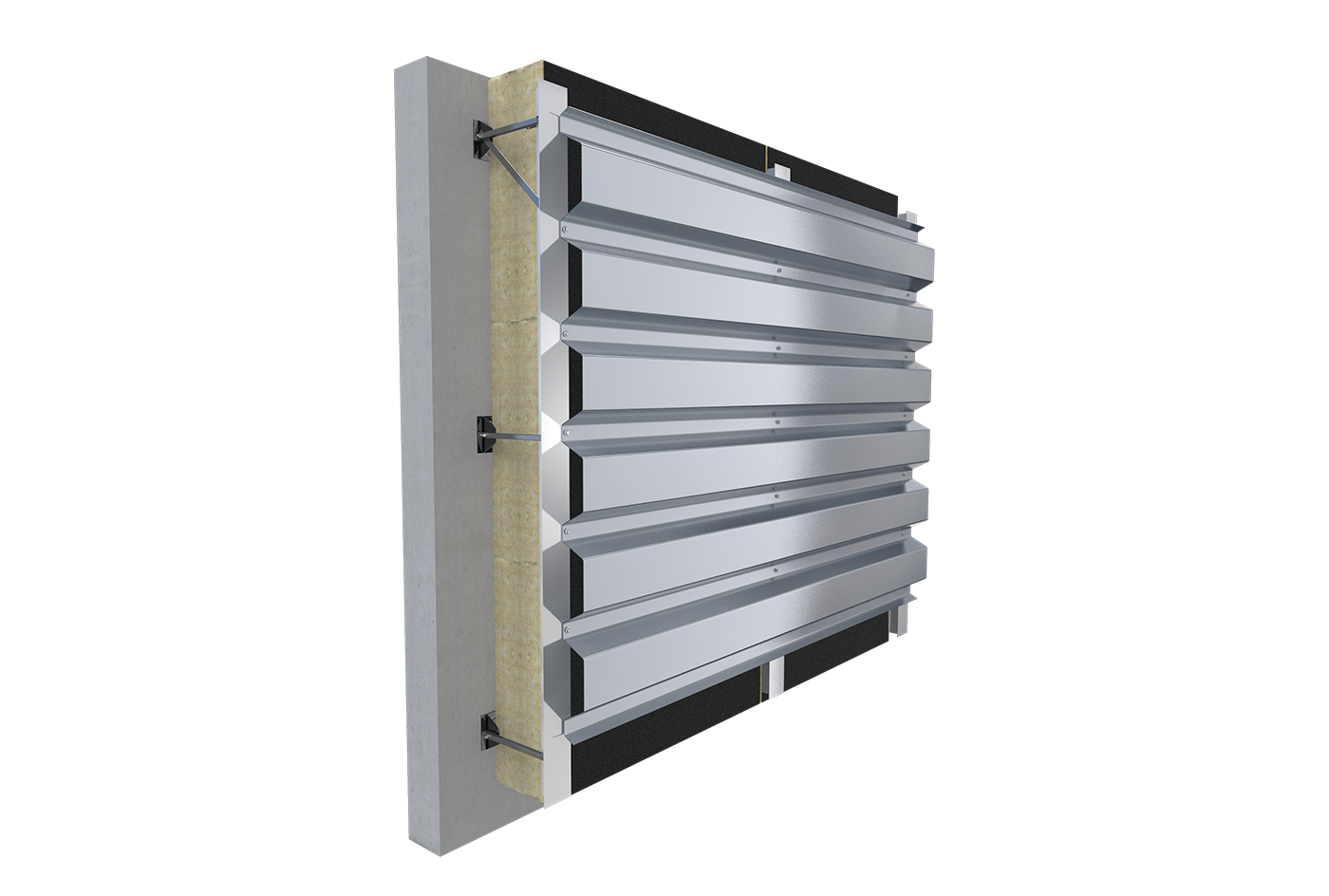

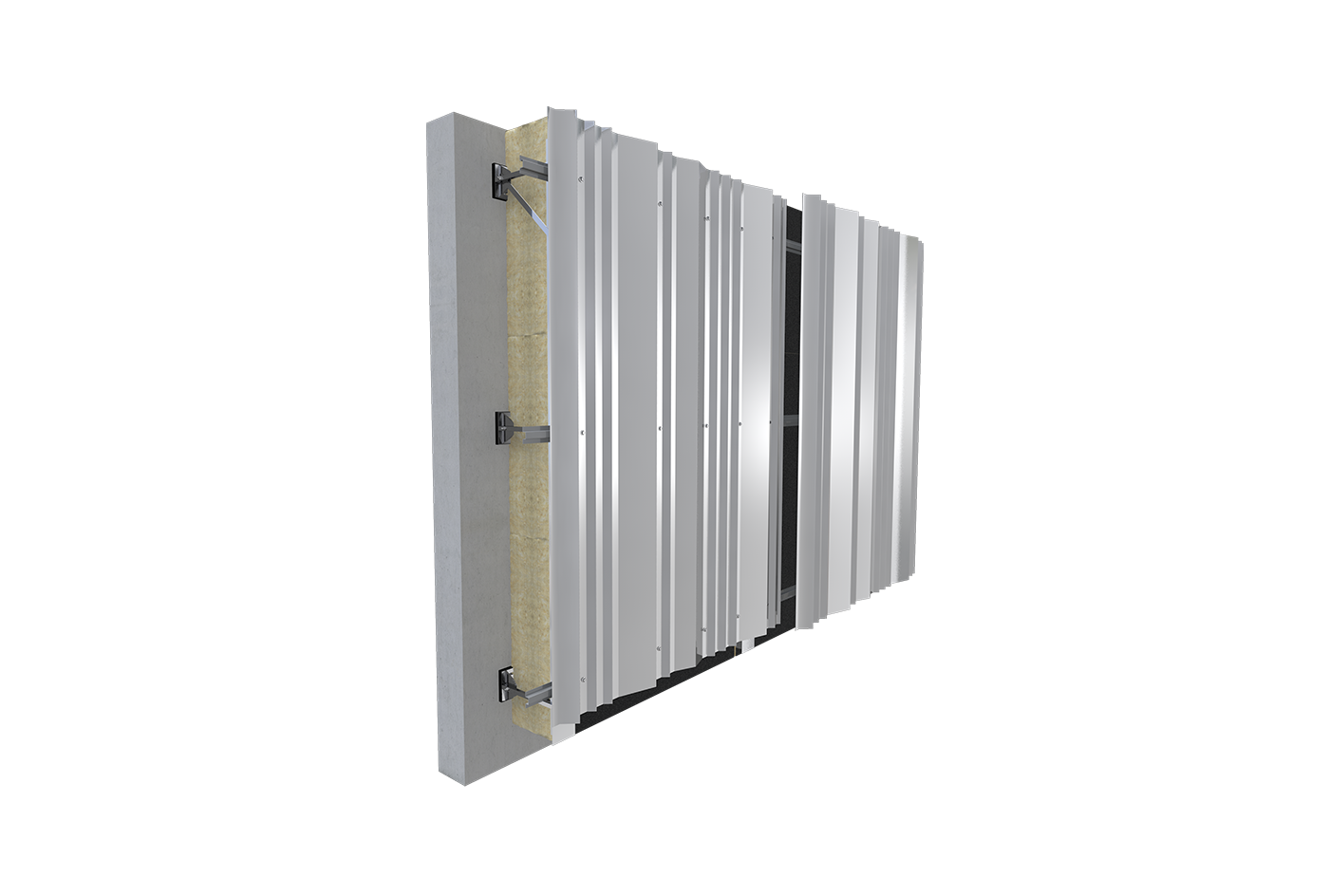

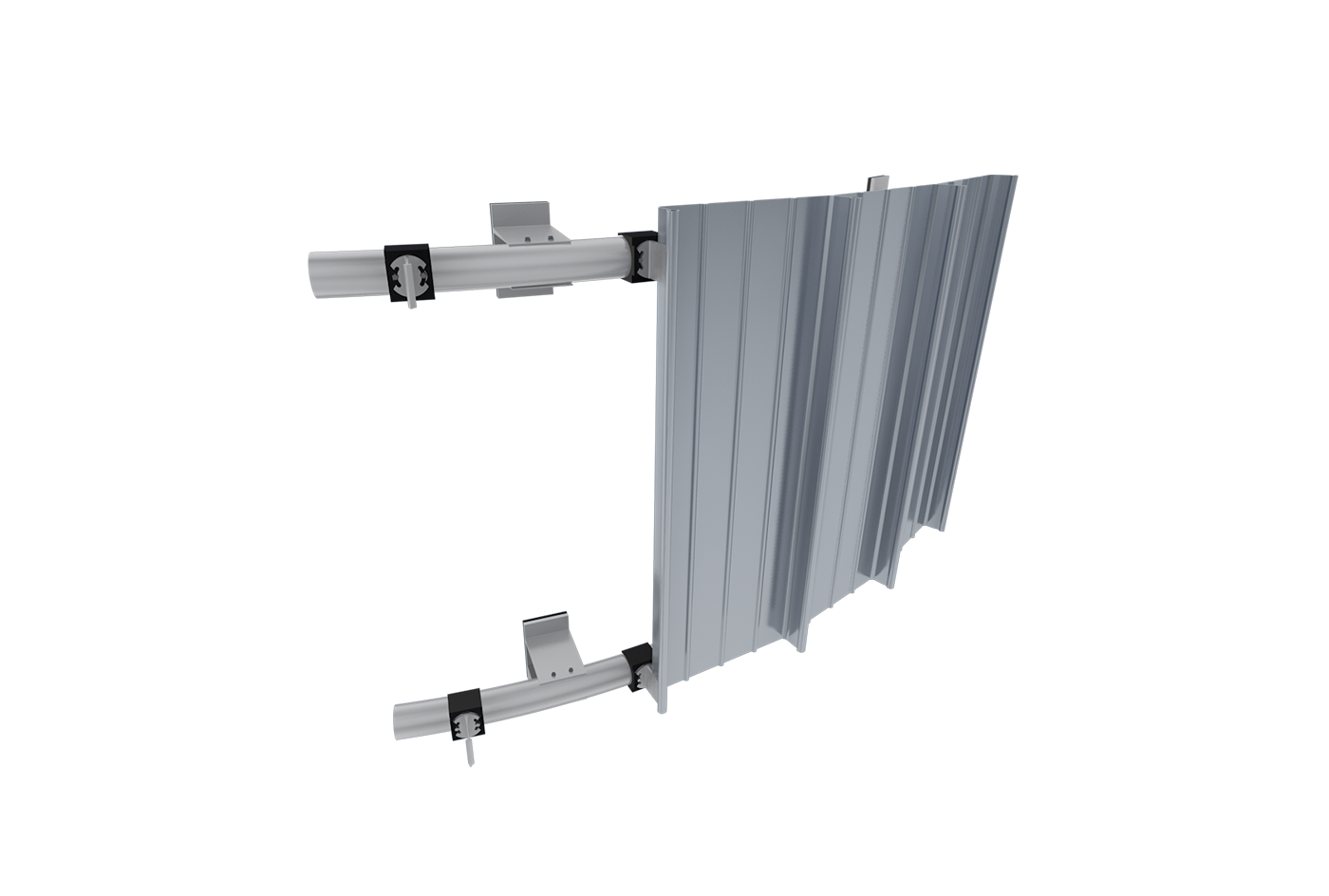

Substructure systems and façade systems with corrugated and trapezoidal profiles

For tolerance compensation and to avoid thermal bridges

The substructure is anchored in the outer wall as a link between the load-bearing wall and the façade cladding. In this way, it transfers the weight of the façade cladding to the structure of the building. BEMO offers innovative substructure systems to compensate for tolerances, especially for rear-ventilated façades, and at the same time ensures a construction free of thermal bridges. We will be happy to work with you to find the right substructure for your individual requirements, taking all circumstances into account.

Inspiration

Manching airfield maintenance hangar

Rheinfelden Industrial School

Eislingen gym

Emser Thermenhotel

Apartment building in Münchenstein

360° Service

Professional technical support

In the BEMO design office system-experienced technicians and engineers work all equipped with the latest 3D design technology. Some of it is developed in-house. Your project benefits from an initial consultation on the implementation of the desired design, a wide choice of materials and shaping, an overview of all technical details and static preliminary measurements. On top of that, BEMO takes care of the complete implementation and workshop planning.

To optimise your project economically, cost estimates, technical optimisations or even variant calculations are aimed at any project stage. 3D measurements build the foundation for our well thought-out and assembly-friendly systems and implementation in 3D design. This is what we understand a comprehensive partnership.