The refurbishment of existing roofs is always challenging and therefore requires well thought-out planning and effective preparation. Precise preliminary planning is essential in order not to impair ongoing operations and to minimise safety risks.

This means that a inspection of the roof must first be carried out to determine the exact substrate and establish which fastening methods are possible. It must be analysed in advance where and how static loads can be safely transferred into the building and what effects this will have. Existing contaminated sites must also be identified, removed and disposed of. The logistics and storage of materials during ongoing operations is another challenge that needs to be overcome.

Diverse substrates require customised solutions

Existing roofs can have a variety of materials and constructions, from old reinforced concrete ceilings to stretch ceilings from the 60s and 70s. Thanks to decades of experience, we at BEMO are able to develop customised refurbishment solutions for every challenge. Refurbishments and the development of customised refurbishment solutions are one of our long-standing strengths. In view of the growing importance of existing buildings in the construction sector, we have successfully and comprehensively positioned ourselves in this area for many years, be it in the renovation of roofs or façades.

Combining historical heritage and modern requirements

We faced a particular challenge when renovating a historic shed roof in Switzerland. In addition to the classic requirements for thermal and weather protection, the preservation of the historical character also played a decisive role.

The existing roof consisted of an approx. 8-10 cm thick reinforced concrete ceiling, which was only insulated on the inside with an approx. 5 cm thick cement-bonded wood wool board. This structure is around 60-70 years old and was in urgent need of renovation due to problems with thermal insulation in winter and extreme heat in summer. In addition, there were leaks and there was a desire to install a photovoltaic system. Due to the historical protection of the building, close coordination with the authorities and the submission of samples were therefore essential.

Innovation and precision in timber construction

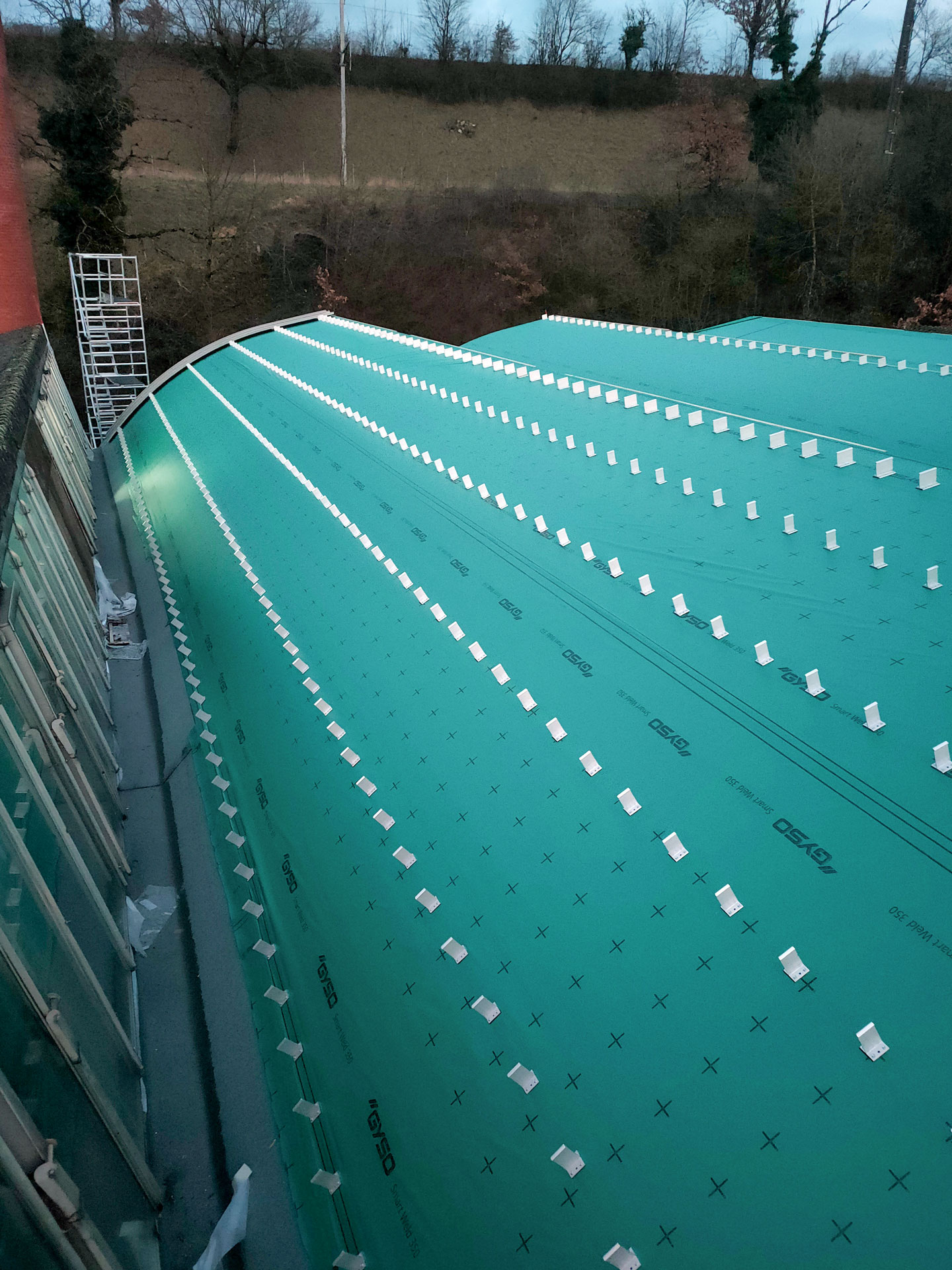

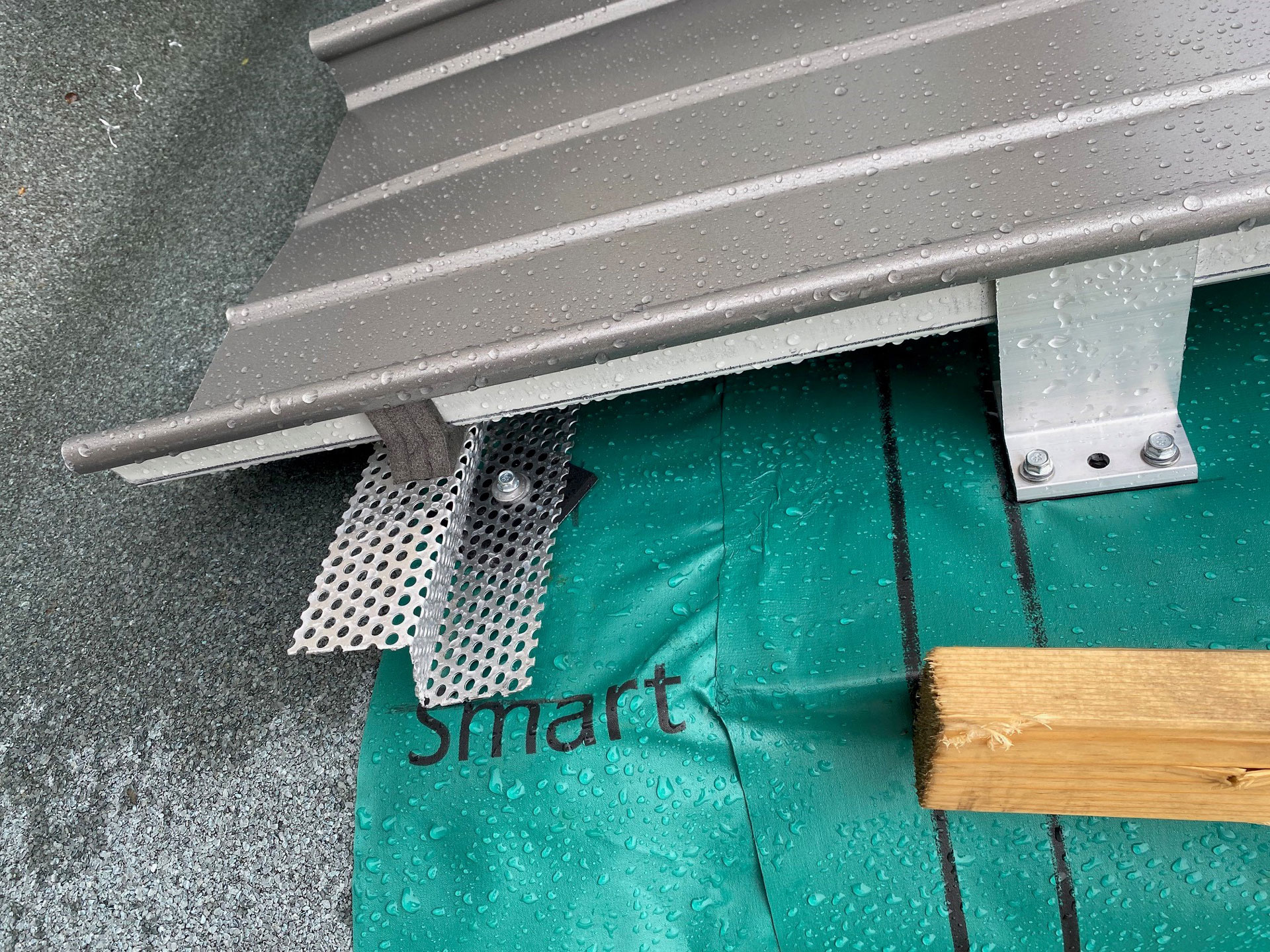

The new structural build-up of the roof was realised with a timber construction using curved beams to compensate for the large unevenness in the concrete. Prefabrication took place in the workshop using a template. During installation, the beams were underlaid and firmly bolted to the old existing ceiling using timbers. Plastic dowels were deliberately avoided to ensure a stable connection between the existing structure and the new one. The wooden formwork on top was protected from the weather by a underlay membrane. Cellulose was blown into the gaps for insulation. Alternatively, hat profiles and pre-assembled halters can be used, which can be adapted and aligned to the existing structure using short pieces.

BEMO standing seam system: durability and sustainability

At the heart of the refurbishment was the BEMO standing seam system, which not only offered a non-penetrative solution, but also guaranteed a long service life and high resistance to the elements. A curved BEMO standing seam roof was used for the new weatherproof structure, matching the uneven, straight roof shape that already existed at the beginning and end. The curving was carried out in the factory using plans and a template, using the exact shape of the timber beams as a guide to ensure the standing seam sheets fitted perfectly with the new structure. The client was delighted with the penetration-free solution and recognised the advantage of the clamp-on PV substructure solution, which does not require screws in the water-bearing layer. The roof system is also characterised by a life expectancy of well over 50 years. During realisation, the height of the rear ventilation was adjusted to ensure a better fit for connections and transitions. For existing buildings and renovation projects, customised and flexible systems that can adapt to the circumstances are essential.

Simplicity, speed and tightness

Thanks to precise planning and careful execution, the renovation of the shed roof was completed in a short time and with minimal disruption to ongoing operations. Fitted with a weather-protective underlay membrane and rebated with standing seam sheets, the historic building now shines in new splendour and offers its residents a modern, energy-efficient living space.