In swimming pools, unusual architecture can provide special bathing fun. However, it is not only a question of unique architecture, but also of the right construction. Because with swimming pools special conditions have to be met in the construction of the building envelope. A thermal building envelope is required, which plays a central role in addition to the system and building technology – especially on the swimming pool roof.

What requirements does a thermal building envelope in swimming pools have to meet?

Swimming pools have increased requirements – especially in the area of plant and building technology, but also in the area of building physics. The building has to be kept warm in winter and cool in summer – so that it doesn’t get “too tropical” for bathing fun. In other words, the thermal building envelope is another essential concept in addition to the system technology with ventilation.

In addition, there is the fact that a swimming pool is subject to high hygric loads – i.e. a permanently increased indoor temperature combined with high humidity. The requirements for the building envelope – and especially for the swimming pool roof – are particularly high in winter. Extremely low U-values of the thermal building envelope (roof and facade construction) are therefore of great importance.

How can this be implemented and which options of the superstructures are suitable for this?

The roof structure should consist of a material on the inside (on the primary side exposed to heat and moisture) that has a good regulating effect and must not corrode under any circumstances. timber is suitable for this in combination with a structure that is free of and / or has reduced thermal bridges. Alternatively, hybrid structures with a supporting shell as a supporting structure and a suspended ceiling are also suitable for the thermal building envelope.

The swimming pool roof can then be built on top of it, depending on the requirements, with thermal insulation of almost any height and specification. In order to keep the thermal insulation at an almost perfect level, GRP halters are suitable, which are not only passivhouse certified, but also do not represent a significant thermal bridge. Depending on the requirements for summer heat insulation and sound insulation, the insulation can be tread-resistant or soft.

Building materials and construction methods of the thermal building envelope – How do you improve energy consumption?

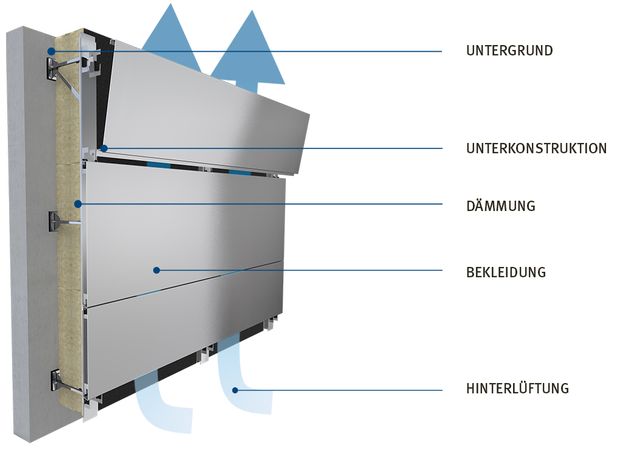

In the wall or facade, curtain-wall, rear-ventilated constructions offer the highest level of security. This means that conventional supporting structures made of reinforced concrete, masonry or timber structures can be used for the thermal building envelope. In the case of timber, it is particularly important that a functioning vapour barrier is used on the warm side of the insulation, since leaks can quickly lead to damage due to the high level of moisture.

Despite this latent danger with timber, rear ventilation offers extreme safety. Because moisture, which may diffuse through the component, can dry off again and there is no damage to the construction. Here, too, U-values play a central role – above all, effective U-values including punctual or linear thermal bridges. Only then can a swimming pool be operated economically on a long-term and sustainable basis.

Why is a standing seam roof ideal as a swimming pool roof?

For various reasons, a standing seam roof is the ideal roof for the construction of a thermal building envelope:

- Due to the very low and tested SD value, it brings a significantly higher level of security than, for example, seals.

- It allows any structures on the roof to be installed sustainably, safely and economically (double security).

- If there are leaks in the vapour barrier or if they are created during installation, some of the moisture can still diffuse out through the upstands of the standing seam.

There is also another point: Regardless of whether it is photovoltaic, solar thermal or snow guard – everything can be set up and permanently attached without a single penetration. This creates a functioning roof system from the inside to the outside and from the outside to the inside.

Which facade claddings are suitable for a VHF construction?

After the high humidity is extracted via exhaust air systems, you should primarily pay attention to the suitable materials in the area of the air outlets. Accordingly, durable materials such as stainless steel or aluminum should be used in these areas. The cladding can, for example, be an aluminum composite panel (attached visibly or invisibly). Alternatively, special panels or sidings can also be used – perforated or closed over a large area, depending on the architecture or design. It is important that the rear ventilation and the connections used work.

Refurbishment of Mittweida municipal library

Germersheim Fire Department

Car wash Mr. Wash

Nothing should stand in the way of your thermal building envelope: We will find the right solution with you. Contact us! We clarify your questions, advise you comprehensively and support you as experts for individual project solutions for building envelopes.